- Oil & Gas

- Chemical & Petrochemical

- Power Plant

-

Features AMETEK Process Instruments has been the leader in tail gas analysis for over 40 years-with more than 1,100 installed 880 NSL analyzers and more than 100 million hours of run time. The 888, the successor of the 880 NSL uses field-proven and highly reliable UV technology to accurately monitor the H2S and SO2 concentrations in sulfur recovery tail gas. This compact, rugged analyzer mounts directly on the process pipe, eliminating the complexity and safety issues of fiber optic coupled photometers. The 888 is the evolution of a well proven formula. All the best elements of the iconic 880 NSL are still there; Four year lamp life, no shelter required and steam blow back for ammonia salts. Building on this success the 888 offers improvements in a number of key areas. Industrial

Features AMETEK Process Instruments has been the leader in tail gas analysis for over 40 years-with more than 1,100 installed 880 NSL analyzers and more than 100 million hours of run time. The 888, the successor of the 880 NSL uses field-proven and highly reliable UV technology to accurately monitor the H2S and SO2 concentrations in sulfur recovery tail gas. This compact, rugged analyzer mounts directly on the process pipe, eliminating the complexity and safety issues of fiber optic coupled photometers. The 888 is the evolution of a well proven formula. All the best elements of the iconic 880 NSL are still there; Four year lamp life, no shelter required and steam blow back for ammonia salts. Building on this success the 888 offers improvements in a number of key areas. Industrial -

Features In the past, conventional Claus Sulfur recovery processes were adequately controlled on the basis of ratio or excess process air. The development of new and modified sulfur recovery processes has dramatically changed the analytical requirements placed on the tail gas analyzer. These applications require accurate chemical concentration data over wide dynamic ranges. Selective oxidation processes may require the analyzer to control the H2S/SO2 ratio at values ranging from 1:7 to greater than 10:1. In addition there is an increased need to provide reliable process data during upset conditions to endure correct response to such conditions. Industrial

Features In the past, conventional Claus Sulfur recovery processes were adequately controlled on the basis of ratio or excess process air. The development of new and modified sulfur recovery processes has dramatically changed the analytical requirements placed on the tail gas analyzer. These applications require accurate chemical concentration data over wide dynamic ranges. Selective oxidation processes may require the analyzer to control the H2S/SO2 ratio at values ranging from 1:7 to greater than 10:1. In addition there is an increased need to provide reliable process data during upset conditions to endure correct response to such conditions. Industrial- Oil & Gas

- Chemical & Petrochemical

-

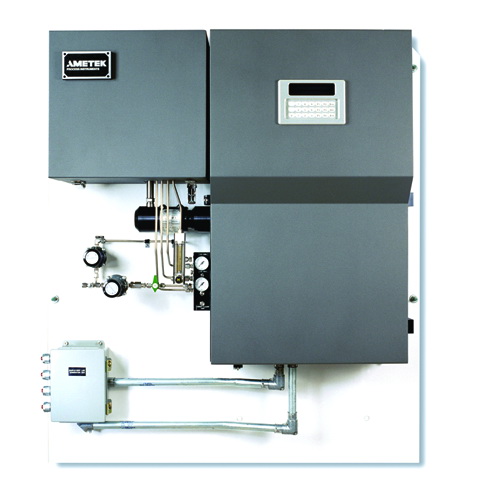

Features The 914 is a built-to-order Continuous Emission Monitor (CEM) that includes all the components needed for a compliance monitoring and reporting project. The system uses dry extractive sampling techniques designed to meet government regulations for all types of compliance monitoring. The sample extraction system of the 914 combines a temperature controlled sample conditioning unit and a heated sampling line to ensure the integrity of the sample gas is reliably maintained. The sample gas is then dried (moisture removed) as required and introduced into the instruments for analysis. Industrial

Features The 914 is a built-to-order Continuous Emission Monitor (CEM) that includes all the components needed for a compliance monitoring and reporting project. The system uses dry extractive sampling techniques designed to meet government regulations for all types of compliance monitoring. The sample extraction system of the 914 combines a temperature controlled sample conditioning unit and a heated sampling line to ensure the integrity of the sample gas is reliably maintained. The sample gas is then dried (moisture removed) as required and introduced into the instruments for analysis. Industrial- Oil & Gas

- Chemical & Petrochemical

- Power Plant

-

The 930 H2S Vapour Space Analyzer was developed for sulfur pit storage applications. The 930 has been field proven as one of the industry’s most reliable instruments for monitoring H2S and SO2. The analyzer uses a proprietary high resolution UV technology in a dual beam, multiple wavelength configuration. Resolution better than 0.02 nm is provided by high intensity, line source lamps. These sources emit at a fixed wavelength, providing great measurement stability, and emit low total power, removing the potential for sample photolysis. The dual beam configuration, combined with the reference measurement, ensures low noise performance, with minimal baseline and span drift. Features

The 930 H2S Vapour Space Analyzer was developed for sulfur pit storage applications. The 930 has been field proven as one of the industry’s most reliable instruments for monitoring H2S and SO2. The analyzer uses a proprietary high resolution UV technology in a dual beam, multiple wavelength configuration. Resolution better than 0.02 nm is provided by high intensity, line source lamps. These sources emit at a fixed wavelength, providing great measurement stability, and emit low total power, removing the potential for sample photolysis. The dual beam configuration, combined with the reference measurement, ensures low noise performance, with minimal baseline and span drift. Features- Simultaneous, accurate measurement of both H2S and SO2

- Output alarms for H2S (LEL) and SO2 (smoldering fire)

- Common design with Model 900 (air demand) and Model 910 (stack gas)

- Exceptional baseline stability

- Improved sample conditioning via ASR Probe

- Oil & Gas

- Chemical & Petrochemical

- Power Plant

-

The 931 uses a sophisticated UV-VIS photometer to measure any single UV-absorbing gas species for process monitoring and control. Additional IR and thermal conductivity sensors capable of detecting non-UV absorbing species, such as CO2 and H2 can be incorporated into the design. The 931 is provided as an explosion-proof package making it suitable for most chemical and petrochemical applications. Features

The 931 uses a sophisticated UV-VIS photometer to measure any single UV-absorbing gas species for process monitoring and control. Additional IR and thermal conductivity sensors capable of detecting non-UV absorbing species, such as CO2 and H2 can be incorporated into the design. The 931 is provided as an explosion-proof package making it suitable for most chemical and petrochemical applications. Features- Class I, Division 1, or ATEX II 2 G Hazardous Area Rating

- Direct measurement

- Provision to return sample to process (with heated acid gas probe option)

- Minimal sample conditioning

- Dual-beam, dual-wavelength design

- Optional detectors available (thermal conductivity-hydrogen and IR-hydrocarbon

- Oil & Gas

- Chemical & Petrochemical

- Power Plant

-

The IPS-4 is a huge step forward in capability and reliability for process spectrophotometers. The analyzer is capable of measuring up to eight wavelengths in a gas or liquid phase sample. Sample handling and conditioning systems are available as an option that is integrated into the IPS-4s sample cell enclosure. Features

The IPS-4 is a huge step forward in capability and reliability for process spectrophotometers. The analyzer is capable of measuring up to eight wavelengths in a gas or liquid phase sample. Sample handling and conditioning systems are available as an option that is integrated into the IPS-4s sample cell enclosure. Features- Measures up to 8 wavelengths

- Low cost of ownership

- No annual, routine maintenance

- No moving parts

- IP65 (NEMA 4X optional)

- Integrated, customizable sample system

- Ethernet and MODBUS communications

- Oil & Gas

- Chemical & Petrochemical

- Power