Features

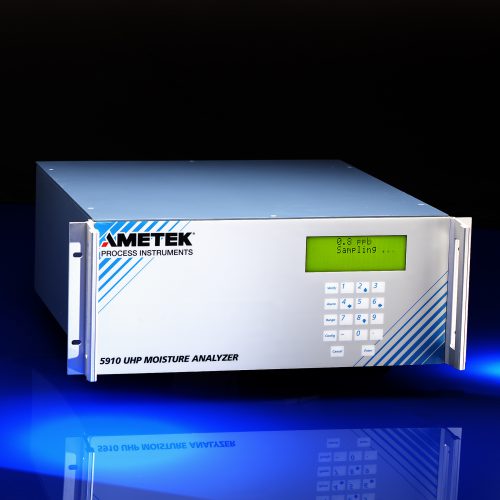

The 5910 analyzer provides a quantum leap forward in performance across all measurable parameters. The 5910 is sensitive to changes in moisture concentration of less than 500 pptv. We know this because the nominal noise level is below 50 pptv. The result of these phenomenal abilities is an accuracy of better than ±100 pptv or ±10% of reading.

Typical Applications

Continuous Monitoring : Continuous moisture analysis is a valuable tool for quality assurance and process monitoring. As a quality assurance analyzer, the 5910 verifies that specified gas purity levels are maintained at on‑site separation, bulk delivery and distribution system transfer points, and ultimately, at points-of-use. The 5910 satisfies all the demands of continuous monitoring principally low detection limit, high measurement accuracy, and internal verification.

Analytical Carts : The 5910 is the perfect analyzer for temporary monitoring applications for verifying installation, maintenance, or repair of gas distribution systems. Such temporary or spot testing makes excellent use of the unique combination of capabilities provided by the 5910—very fast response speed, especially to decreasing moisture concentrations for monitoring system dry-down; complete compatibility with O2, H and inerts; rapid start-up response; and the ability to quickly change from one gas to another.

Industrials

- Oil & Gas

- Chemical & Petrochemical