- Connects copper busbar to copper busbar, nVent ERIFLEX Flexibar or power shunt

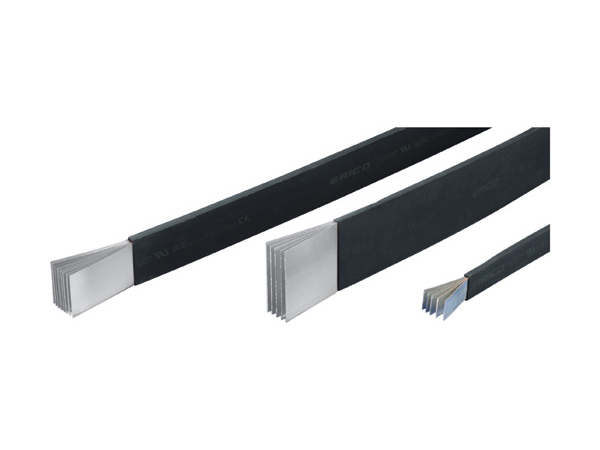

- Made with non-magnetic materials for high current connections between nVent ERIFLEX Flexibar and rigid busbars such as transformer terminals

- Rigid design assures even contact pressure

- Installs quickly and easily

- Ideal for on site modifications

- RoHS compliant

- Very compact clamp for connecting cable conductors or nVent ERIFLEX Flexibar to busbar without drilling

- Conductor is clamped with a pressure plate

- Clamps can be mounted and slid into position on busbar prior to connecting conductors

- Connections can be added after busbar has been mounted

- Single screw locks clamp and makes connection

- EAC compliant

- RoHS compliant

- Connects nVent ERIFLEX Flexibar to punched busbar

- Allows for excellent electrical contact

- Compact, space saving design

- Installs quickly and easily

- Ideal for on site modifications

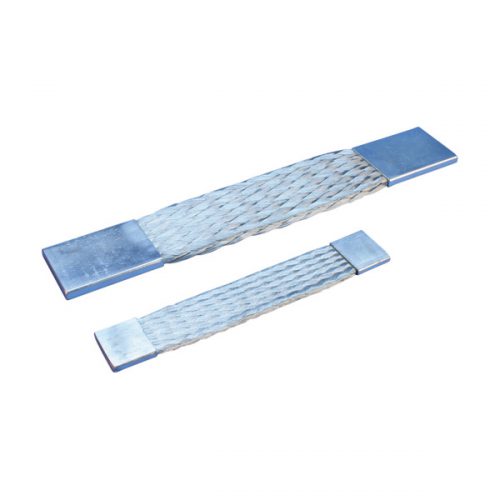

- Connects two copper busbars together or nVent ERIFLEX Flexibar to copper busbar

- Two ribbed plates complete with screws

- Allows for excellent electrical contact

- Installs quickly and easily

- Ideal for on site modifications

- RoHS complian

- Connects nVent ERIFLEX Flexibar to copper busbar

- Two plates complete with screws

- Allows for excellent electrical contact

- Installs quickly and easily

- Ideal for on site modifications

- RoHS compliant