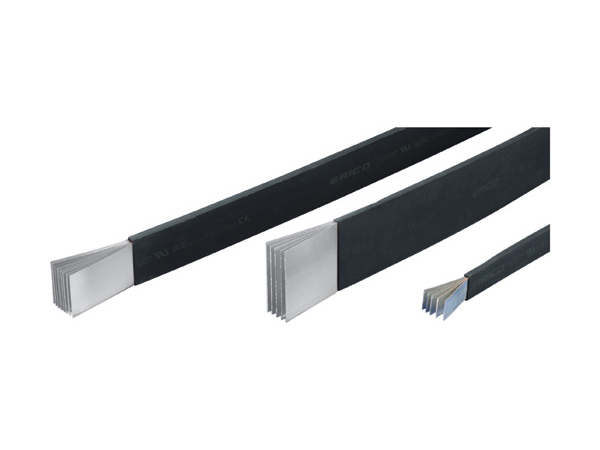

- Thin layers of tinned electrolytic copper formed into a stack

- Full range from 19.5 mm² up to 1200 mm² and 125 A to 2800 A

- Insulated by high-resistance, halogen free, flame retardant and low smoke material with less than 20% contact with conductor for high flexibility

- Easily bent, folded, and twisted, improving assembly flexibility, shortening connections, and decreasing footprint

- Dramatically smaller and more flexible than comparable cable based on ampacity

- Better power density than cable with lower skin effect ratio

- Connections made by punching and bolting directly through the copper laminates or clamping onto the end of the nVent ERIFLEX Flexibar

- No lugs needed, reducing installation time and improving resistance to vibration

- Weight savings and material savings compared to wire alternatives

- Reduces total installation cost

- Traceability codes and designation part numbers printed on insulation

- Conforms to NF EN 45545 obtaining an HL2 classification for chapters R22 and R23

- 100% production dielectric tested

- RoHS compliant

- Tinned copper allows for copper or aluminum conductor connections

- Halogen free solution for applications requiring a low smoke solution

- Thin layers of bare electrolytic copper formed into a stack

- Silver or tinned nVent ERIFLEX Flexibar Summum available on request

- Insulated by halogen-free, high-temperature silicone

- Easily bent, folded, and twisted, improving assembly flexibility, shortening connections, and decreasing footprint

- Dramatically smaller and more flexible than comparable cable based on ampacity

- Better power density than cable with lower skin effect ratio

- Connections made by punching and bolting directly through the copper laminates, clamping onto the end of the nVent ERIFLEX Flexibar, or welding using nVent ERICO Cadweld

- No lugs needed, reducing installation time and improving resistance to vibration

- Weight savings and material savings compared to wire alternatives

- Reduces total installation cost

- Very high resistance to UV and ozone

- Limiting oxygen index (LOI)

- Traceability codes and designation part numbers printed on insulation

- Conforms to NF EN 45545 obtaining an HL2 classification for chapters R22 and R23

- EAC compliant

- RoHS compliant

- Suitable for all main molded case circuit breakers

- Resistant to vibration, improving reliability and performance

- Insulated by high-resistance, halogen free, flame retardant and low smoke material

- Tinned copper provides superior corrosion resistance

- Improves assembly flexibility and aesthetics

- Quick and easy installation

- No additional cutting, stripping, crimping and punching needed

- Integral palm without lugs or terminals reduces material and assembly weight

- Conforms to NF EN 45545 obtaining an HL2 classification for chapters R22 and R23

- DNV GL® and Bureau Veritas certified for marine and offshore applications

- Small wire diameter provides maximum flexibility

- Dramatically smaller and more flexible than comparable cable based on ampacity

- Better power density than cable with lower skin effect ratio

- Reduces total installation cost

- RoHS compliant

- Tinned copper allows for copper or aluminum conductor connections