Features

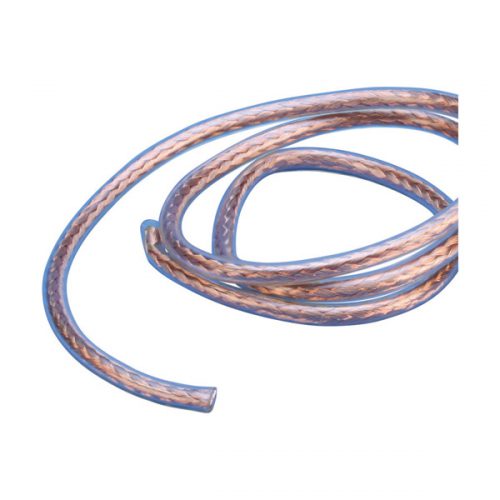

CPI Grounding and Bonding Braid, Stainless Steel

High-quality CPI stainless steel grounding and bonding braids can be installed in extremely corrosive environments, like offshore applications or coastal applications. The full range of CPI braids are ideal for applications using stainless steel pipe or tanks, like the food and beverage industry, building industry, transportation, oil and chemical industry. nVent ERIFLEX offers 316L stainless steel braids and lugs, one of the highest resistant stainless steel options on the market. Our proprietary manufacturing process has been optimized to provide the best braiding, crimping, cutting and punching

- Superior abrasion, corrosion, chemical and UV resistance make CPI braids ideal for outdoor applications

- Great for expansion joints where constant movement requires a flexible and durable solution

- Ready to use out of the box, eliminates the need for cutting, stripping, crimping and punching

- Quick and easy to install

- Resistant to vibration and fatigue, reducing maintenance

- Will not rust or discolor, so the appearance will never fade or change

- Excellent electrical contact

- No additional lugs or terminals needed

- Non-magnetic material

- Recommended by the EMC/EMI directives

- Performs to the class C5 (very high) category as per ISO® 12944-2

- EAC compliant

- RoHS compliant

4.4 CPI