- Oil & Gas

- Chemical & Petrochemical

-

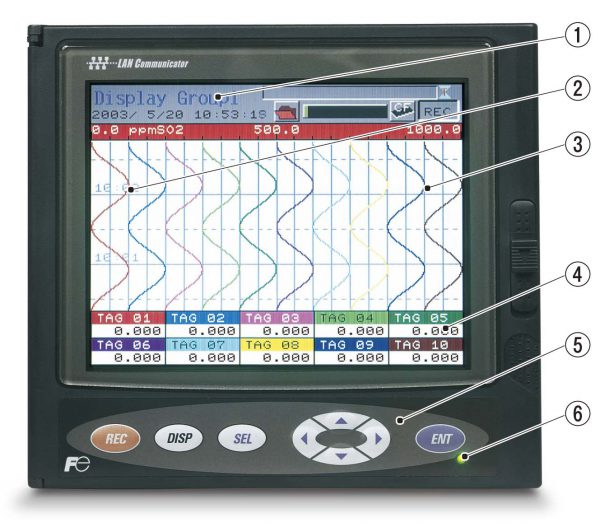

Features The 3050 Moisture Analyzer series measures trace levels of moisture in a gas through the use of a quartz-crystal oscillator sample cell. AMETEK is the leader in quartz-crystal technology, which for thirty years has offered significant advantages over other measurement techniques: • Most accurate trace moisture measurement technology available • Responds far faster to both increasing and decreasing moisture levels • Specific to moisture in most applications • Provides a much more rugged sensor Because of these advantages, the quartz-crystal oscillator has become the industry standard for applications ranging from ultrahigh purity semiconductor gases to natural gas streams containing 30% H2S. Now, the 3050 analyzers bring the benefits of quartz-crystal technology to a broad spectrum of moisture applications. AME Vision Display Unit AMEVision allows users to continually monitor the measurement and diagnostic information from up to eight 3050 series moisture analyzers. AMEVision provides real-time moisture measurements, trend data, and details a variety of maintenance and troubleshooting information from the 3050. Users can communicate with AMEVision via Modbus RS485 and Ethernet LAN. • Compatible with 3050 models OLV, SLR, DO, and TE • Connect up to eight analyzers on one unit • Trend history • Automatic data capture and logging • Calibration history • Alarm history Industrial

Features The 3050 Moisture Analyzer series measures trace levels of moisture in a gas through the use of a quartz-crystal oscillator sample cell. AMETEK is the leader in quartz-crystal technology, which for thirty years has offered significant advantages over other measurement techniques: • Most accurate trace moisture measurement technology available • Responds far faster to both increasing and decreasing moisture levels • Specific to moisture in most applications • Provides a much more rugged sensor Because of these advantages, the quartz-crystal oscillator has become the industry standard for applications ranging from ultrahigh purity semiconductor gases to natural gas streams containing 30% H2S. Now, the 3050 analyzers bring the benefits of quartz-crystal technology to a broad spectrum of moisture applications. AME Vision Display Unit AMEVision allows users to continually monitor the measurement and diagnostic information from up to eight 3050 series moisture analyzers. AMEVision provides real-time moisture measurements, trend data, and details a variety of maintenance and troubleshooting information from the 3050. Users can communicate with AMEVision via Modbus RS485 and Ethernet LAN. • Compatible with 3050 models OLV, SLR, DO, and TE • Connect up to eight analyzers on one unit • Trend history • Automatic data capture and logging • Calibration history • Alarm history Industrial -

Features 5100 Based on Tunable Diode Laser Absorption Spectroscopy (TDLAS) The 5100 hosts a single laser platform to measure a single gas analyte. The device can measure any one of the following gas analytes: water vapor, methane, hydrogen sulfide, carbon dioxide, and oxygen in process or flue gas. If water vapor is the measured gas analyte, methane can be monitored additionally at percent levels using the same laser. A key feature of the 5100 is the use of a sealed reference cell, which contains a known amount of analyte gas measured, for referencing the emission wavelength of the laser. The use of a reference cell enables both the ability to line-lock the lasers and to continuously verify the instrument calibration. The 5100 is designed to handle sample gases with dew points as high as 55ºC. For higher temperature dew point applications the 5100HD is recommended.

Features 5100 Based on Tunable Diode Laser Absorption Spectroscopy (TDLAS) The 5100 hosts a single laser platform to measure a single gas analyte. The device can measure any one of the following gas analytes: water vapor, methane, hydrogen sulfide, carbon dioxide, and oxygen in process or flue gas. If water vapor is the measured gas analyte, methane can be monitored additionally at percent levels using the same laser. A key feature of the 5100 is the use of a sealed reference cell, which contains a known amount of analyte gas measured, for referencing the emission wavelength of the laser. The use of a reference cell enables both the ability to line-lock the lasers and to continuously verify the instrument calibration. The 5100 is designed to handle sample gases with dew points as high as 55ºC. For higher temperature dew point applications the 5100HD is recommended.- All digital signal processing

- Web-based interface

- Connectivity by modbus, ethernet and analog

- Real-time performance monitoring

- Fully integrated sample handling

- Resistant to contamination

- Reference Cell enables Line Lock and Span Verification The 5100 offers high specificity, selectivity, speed of response and great reliability

- Oil & Gas

- Chemical & Petrochemical

-

Features The 241CE II Hydrocarbon Dew Point Analyzer is a quality control tool for natural gas processing, distribution and consumption. Detection and measurement of hydrocarbon dewpoint is achieved in a single cell, single cycle operation. The dew point analyzer uses patented chilled-mirror technology. With the 241CE II Hydrocarbon Dew Point Analyzer, all monitoring and measuring of dew points is done automatically under control of an onboard computer, rather than by an operator. The dew point analyzer was designed for unattended operation. Accurate and objective direct measurement of hydrocarbon dew point temperature at pipeline pressure or Cricondentherm

Features The 241CE II Hydrocarbon Dew Point Analyzer is a quality control tool for natural gas processing, distribution and consumption. Detection and measurement of hydrocarbon dewpoint is achieved in a single cell, single cycle operation. The dew point analyzer uses patented chilled-mirror technology. With the 241CE II Hydrocarbon Dew Point Analyzer, all monitoring and measuring of dew points is done automatically under control of an onboard computer, rather than by an operator. The dew point analyzer was designed for unattended operation. Accurate and objective direct measurement of hydrocarbon dew point temperature at pipeline pressure or Cricondentherm- Proprietary three-stage filter provides superior protection

- Designed for unattended operation with low maintenance

- Compact design allows mounting in optional enclosures

- Digital communications vis Modbus RTU protocol

- Fully integrated sample system

- Hydrocarbon dew point temperature current output

- Oil & Gas

- Chemical & Petrochemical

-

Features AMETEK’s 2850 Moisture Analyzer establishes a new standard in clean gas moisture analyzers: ultrafast response speed, exceptional accuracy, virtually no interferences, multigas compatibility, and on-board measurement verification. This unique combination of capabilities makes the 2850 the moisture analyzer of choice for monitoring process desiccant dryers, instrument air dryers, or air separators, and for industrial gas production and quality assurance. Typical Applications

Features AMETEK’s 2850 Moisture Analyzer establishes a new standard in clean gas moisture analyzers: ultrafast response speed, exceptional accuracy, virtually no interferences, multigas compatibility, and on-board measurement verification. This unique combination of capabilities makes the 2850 the moisture analyzer of choice for monitoring process desiccant dryers, instrument air dryers, or air separators, and for industrial gas production and quality assurance. Typical Applications- Industrial gas production and quality assurance

- Cryogenic air separation

- Process dryers

- Oil & Gas

- Chemical & Petrochemical

-

Features The 3050 Moisture Analyzer series measures trace levels of moisture in a gas through the use of a quartz-crystal oscillator sample cell. AMETEK is the leader in quartz-crystal technology, which for thirty years has offered significant advantages over other measurement techniques:

Features The 3050 Moisture Analyzer series measures trace levels of moisture in a gas through the use of a quartz-crystal oscillator sample cell. AMETEK is the leader in quartz-crystal technology, which for thirty years has offered significant advantages over other measurement techniques:- Most accurate trace moisture measurement technology available

- Responds far faster to both increasing and decreasing moisture levels

- Specific to moisture in most applications

- Provides a much more rugged sensor Because of these advantages, the quartz-crystal oscillator has become the industry standard for applications ranging from ultrahigh purity semiconductor gases to natural gas streams containing 30% H2S. Now, the 3050 analyzers bring the benefits of quartz-crystal technology to a broad spectrum of moisture applications. AME Vision Display Unit AMEVision allows users to continually monitor the measurement and diagnostic information from up to eight 3050 series moisture analyzers. AMEVision provides real-time moisture measurements, trend data, and details a variety of maintenance and troubleshooting information from the 3050. Users can communicate with AMEVision via Modbus RS485 and Ethernet LAN.

- Compatible with 3050 models OLV, SLR, DO, and TE

- Connect up to eight analyzers on one unit

- Trend history

- Automatic data capture and logging

- Calibration history

- Alarm history

- Oil & Gas

- Chemical & Petrochemical

-

Features Critical moisture measurement applications include high purity gas production; olefin manufacture, storage, and transmission; semiconductor gases; and industrial gas production and quality assurance. For these applications and more, turn to the 5800 Moisture Analyzer. This analyzer offers a truly remarkable combination of performance benefits: exceptional accuracy, multi-gas compatibility, fast response speed, and wide measurement range. Industrial

Features Critical moisture measurement applications include high purity gas production; olefin manufacture, storage, and transmission; semiconductor gases; and industrial gas production and quality assurance. For these applications and more, turn to the 5800 Moisture Analyzer. This analyzer offers a truly remarkable combination of performance benefits: exceptional accuracy, multi-gas compatibility, fast response speed, and wide measurement range. Industrial- Oil & Gas

- Chemical & Petrochemical

-

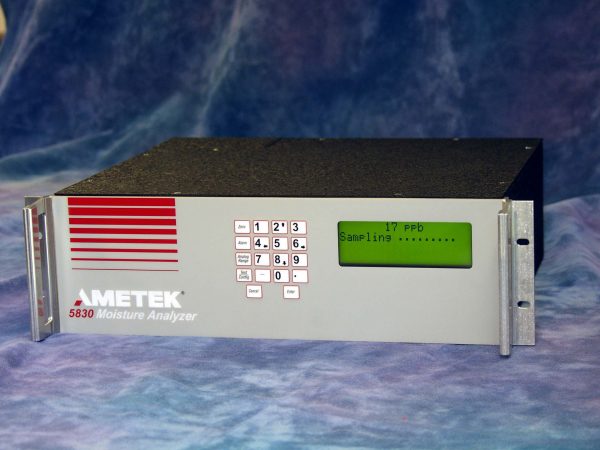

Features Building upon the success of our quartz-crystal moisture measurement technology, the 5830 is an easy-to-use process moisture analyzer that offers a truly remarkable combination of performance features: exceptional accuracy, multi-gas compatibility, fast response speed, and wide measurement range. The 5830 is ideal for critical moisture measurement applications including high purity gas production, semiconductor gases, and industrial gas production and quality assurance. Equipped with an on-line verification system, this state-of-the-art analyzer is designed to rapidly build and maintain operator confidence in its analyses. The verification system allows you to challenge the analyzer’s sensor at will with either a zero gas or an actual NIST-traceable moisture concentration to check both its baseline stability and responsiveness to real moisture. No other manufacturer offers these exclusive abilities in their moisture analyzers. Industrial

Features Building upon the success of our quartz-crystal moisture measurement technology, the 5830 is an easy-to-use process moisture analyzer that offers a truly remarkable combination of performance features: exceptional accuracy, multi-gas compatibility, fast response speed, and wide measurement range. The 5830 is ideal for critical moisture measurement applications including high purity gas production, semiconductor gases, and industrial gas production and quality assurance. Equipped with an on-line verification system, this state-of-the-art analyzer is designed to rapidly build and maintain operator confidence in its analyses. The verification system allows you to challenge the analyzer’s sensor at will with either a zero gas or an actual NIST-traceable moisture concentration to check both its baseline stability and responsiveness to real moisture. No other manufacturer offers these exclusive abilities in their moisture analyzers. Industrial- Oil & Gas

- Chemical & Petrochemicaly

-

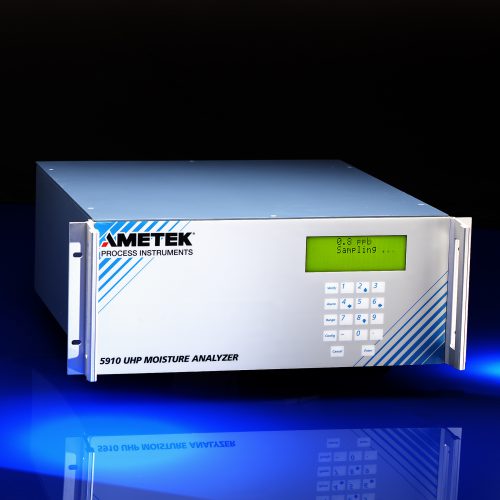

Features The 5910 analyzer provides a quantum leap forward in performance across all measurable parameters. The 5910 is sensitive to changes in moisture concentration of less than 500 pptv. We know this because the nominal noise level is below 50 pptv. The result of these phenomenal abilities is an accuracy of better than ±100 pptv or ±10% of reading. Typical Applications Continuous Monitoring : Continuous moisture analysis is a valuable tool for quality assurance and process monitoring. As a quality assurance analyzer, the 5910 verifies that specified gas purity levels are maintained at on‑site separation, bulk delivery and distribution system transfer points, and ultimately, at points-of-use. The 5910 satisfies all the demands of continuous monitoring principally low detection limit, high measurement accuracy, and internal verification. Analytical Carts : The 5910 is the perfect analyzer for temporary monitoring applications for verifying installation, maintenance, or repair of gas distribution systems. Such temporary or spot testing makes excellent use of the unique combination of capabilities provided by the 5910—very fast response speed, especially to decreasing moisture concentrations for monitoring system dry-down; complete compatibility with O2, H and inerts; rapid start-up response; and the ability to quickly change from one gas to another. Industrials

Features The 5910 analyzer provides a quantum leap forward in performance across all measurable parameters. The 5910 is sensitive to changes in moisture concentration of less than 500 pptv. We know this because the nominal noise level is below 50 pptv. The result of these phenomenal abilities is an accuracy of better than ±100 pptv or ±10% of reading. Typical Applications Continuous Monitoring : Continuous moisture analysis is a valuable tool for quality assurance and process monitoring. As a quality assurance analyzer, the 5910 verifies that specified gas purity levels are maintained at on‑site separation, bulk delivery and distribution system transfer points, and ultimately, at points-of-use. The 5910 satisfies all the demands of continuous monitoring principally low detection limit, high measurement accuracy, and internal verification. Analytical Carts : The 5910 is the perfect analyzer for temporary monitoring applications for verifying installation, maintenance, or repair of gas distribution systems. Such temporary or spot testing makes excellent use of the unique combination of capabilities provided by the 5910—very fast response speed, especially to decreasing moisture concentrations for monitoring system dry-down; complete compatibility with O2, H and inerts; rapid start-up response; and the ability to quickly change from one gas to another. Industrials- Oil & Gas

- Chemical & Petrochemical

-

Features Building upon the success of our quartz-crystal moisture measurement technology, the 5920 is an easy-to-use process moisture analyzer that offers a truly remarkable combination of performance features: multi-gas compatibility, exceptional accuracy, on-line verification, fast response speed, and wide measurement range. The 5920 is ideal for critical moisture measurement applications including high purity gas production and semiconductor gases. Equipped with an on-line verification system, this analyzer is designed to rapidly build and maintain operator confidence in its analyses. The verification system allows you to challenge the analyzer’s sensor at will using a zero gas to check its baseline stability to confirm the sensor’s stability and sensitivity to low ppbv moisture concentrations. Industrial

Features Building upon the success of our quartz-crystal moisture measurement technology, the 5920 is an easy-to-use process moisture analyzer that offers a truly remarkable combination of performance features: multi-gas compatibility, exceptional accuracy, on-line verification, fast response speed, and wide measurement range. The 5920 is ideal for critical moisture measurement applications including high purity gas production and semiconductor gases. Equipped with an on-line verification system, this analyzer is designed to rapidly build and maintain operator confidence in its analyses. The verification system allows you to challenge the analyzer’s sensor at will using a zero gas to check its baseline stability to confirm the sensor’s stability and sensitivity to low ppbv moisture concentrations. Industrial- Oil & Gas

- Chemical & Petrochemical

-

The IPS-4 is a huge step forward in capability and reliability for process spectrophotometers. The analyzer is capable of measuring up to eight wavelengths in a gas or liquid phase sample. Sample handling and conditioning systems are available as an option that is integrated into the IPS-4s sample cell enclosure. Features

The IPS-4 is a huge step forward in capability and reliability for process spectrophotometers. The analyzer is capable of measuring up to eight wavelengths in a gas or liquid phase sample. Sample handling and conditioning systems are available as an option that is integrated into the IPS-4s sample cell enclosure. Features- Measures up to 8 wavelengths

- Low cost of ownership

- No annual, routine maintenance

- No moving parts

- IP65 (NEMA 4X optional)

- Integrated, customizable sample system

- Ethernet and MODBUS communications

- Oil & Gas

- Chemical & Petrochemical

- Power

-

Features AMETEK Process Instruments has been the leader in tail gas analysis for over 40 years-with more than 1,100 installed 880 NSL analyzers and more than 100 million hours of run time. The 888, the successor of the 880 NSL uses field-proven and highly reliable UV technology to accurately monitor the H2S and SO2 concentrations in sulfur recovery tail gas. This compact, rugged analyzer mounts directly on the process pipe, eliminating the complexity and safety issues of fiber optic coupled photometers. The 888 is the evolution of a well proven formula. All the best elements of the iconic 880 NSL are still there; Four year lamp life, no shelter required and steam blow back for ammonia salts. Building on this success the 888 offers improvements in a number of key areas. Industrial

Features AMETEK Process Instruments has been the leader in tail gas analysis for over 40 years-with more than 1,100 installed 880 NSL analyzers and more than 100 million hours of run time. The 888, the successor of the 880 NSL uses field-proven and highly reliable UV technology to accurately monitor the H2S and SO2 concentrations in sulfur recovery tail gas. This compact, rugged analyzer mounts directly on the process pipe, eliminating the complexity and safety issues of fiber optic coupled photometers. The 888 is the evolution of a well proven formula. All the best elements of the iconic 880 NSL are still there; Four year lamp life, no shelter required and steam blow back for ammonia salts. Building on this success the 888 offers improvements in a number of key areas. Industrial- Oil & Gas

- Chemical & Petrochemical

- Power Plant

-

Features In the past, conventional Claus Sulfur recovery processes were adequately controlled on the basis of ratio or excess process air. The development of new and modified sulfur recovery processes has dramatically changed the analytical requirements placed on the tail gas analyzer. These applications require accurate chemical concentration data over wide dynamic ranges. Selective oxidation processes may require the analyzer to control the H2S/SO2 ratio at values ranging from 1:7 to greater than 10:1. In addition there is an increased need to provide reliable process data during upset conditions to endure correct response to such conditions. Industrial

Features In the past, conventional Claus Sulfur recovery processes were adequately controlled on the basis of ratio or excess process air. The development of new and modified sulfur recovery processes has dramatically changed the analytical requirements placed on the tail gas analyzer. These applications require accurate chemical concentration data over wide dynamic ranges. Selective oxidation processes may require the analyzer to control the H2S/SO2 ratio at values ranging from 1:7 to greater than 10:1. In addition there is an increased need to provide reliable process data during upset conditions to endure correct response to such conditions. Industrial- Oil & Gas

- Chemical & Petrochemical

-

Features The 914 is a built-to-order Continuous Emission Monitor (CEM) that includes all the components needed for a compliance monitoring and reporting project. The system uses dry extractive sampling techniques designed to meet government regulations for all types of compliance monitoring. The sample extraction system of the 914 combines a temperature controlled sample conditioning unit and a heated sampling line to ensure the integrity of the sample gas is reliably maintained. The sample gas is then dried (moisture removed) as required and introduced into the instruments for analysis. Industrial

Features The 914 is a built-to-order Continuous Emission Monitor (CEM) that includes all the components needed for a compliance monitoring and reporting project. The system uses dry extractive sampling techniques designed to meet government regulations for all types of compliance monitoring. The sample extraction system of the 914 combines a temperature controlled sample conditioning unit and a heated sampling line to ensure the integrity of the sample gas is reliably maintained. The sample gas is then dried (moisture removed) as required and introduced into the instruments for analysis. Industrial- Oil & Gas

- Chemical & Petrochemical

- Power Plant

-

Description This flowmeter is a clamp-on type ultrasonic flow meter based ontransit-time measuring method. Making full use of the latest electronics and digital signal processing technologies, we realized a compact and lightweight design, and improved the accuracy and easiness to use while keeping with anti-bubble performance. The communication function (MODBUS : Option) is also applicable. Industrials

Description This flowmeter is a clamp-on type ultrasonic flow meter based ontransit-time measuring method. Making full use of the latest electronics and digital signal processing technologies, we realized a compact and lightweight design, and improved the accuracy and easiness to use while keeping with anti-bubble performance. The communication function (MODBUS : Option) is also applicable. Industrials- Oil & Gas

- Pulp & Paper

-

Description This flowmeter is a clamp-on type ultrasonic flow meter based ontransit-time measuring method. Making full use of the latest electronics and digital signal processing technologies, we realized the equipment with improved anti-bubble performance and high accuracy. The communication function (MODBUS : Option) is also applicable. Industrials

Description This flowmeter is a clamp-on type ultrasonic flow meter based ontransit-time measuring method. Making full use of the latest electronics and digital signal processing technologies, we realized the equipment with improved anti-bubble performance and high accuracy. The communication function (MODBUS : Option) is also applicable. Industrials- Oil & Gas

- Pulp & Paper

-

Description Portable type ultrasonic flowmeter consists of a compact and lightweight flow transmitter and a clamp-on detector. With the latest electronics and the digital signal processing technology, it delivers precise measurement while allowing easy operation. New feature : renewed panel design, improved display visibility and connector reliability, and more accessories. Industrials

Description Portable type ultrasonic flowmeter consists of a compact and lightweight flow transmitter and a clamp-on detector. With the latest electronics and the digital signal processing technology, it delivers precise measurement while allowing easy operation. New feature : renewed panel design, improved display visibility and connector reliability, and more accessories. Industrials- Oil & Gas

- Pulp & Paper

-

Description PXF is an extremely compact temperature controller which has 48 x 48 mm, 48 x 96 mm, 96 x 96 mm front panel with a large, white LCD and 58 mm depth behind panel. Develiped as a successor to the standard model PXR, PXF4 features fast sampling speed (50 ms) equal to PXH, highly accurate input indication, and universal input, in addition to various functions of PXG, while achieving a competitive price. Equipped with multiple input/output and sophisticated control function, PXF4 seves as a suitable temperature controller for a wide range of use. Industrials

Description PXF is an extremely compact temperature controller which has 48 x 48 mm, 48 x 96 mm, 96 x 96 mm front panel with a large, white LCD and 58 mm depth behind panel. Develiped as a successor to the standard model PXR, PXF4 features fast sampling speed (50 ms) equal to PXH, highly accurate input indication, and universal input, in addition to various functions of PXG, while achieving a competitive price. Equipped with multiple input/output and sophisticated control function, PXF4 seves as a suitable temperature controller for a wide range of use. Industrials- Oil & Gas

- Pulp & Paper

-

Description This is a paperless recorder that displays measured data on the LCD is real time and stores data in Compact Flash. The type of input such as thermocouple, resistance bulb, D.C. voltage (current), etc. can be arbitrarily set to 6 channels at the maximum. The data stored in Compact Flash can be regenerated on the screen, and the use of supplied support software allows the data to be regenerated on a PC screen. The data recorded in ASCII format can be directly read in a spreadsheet such as Excel, which facilitates the processing on a PC. (The data recorded in binary format cannot be read in.) Industrials

Description This is a paperless recorder that displays measured data on the LCD is real time and stores data in Compact Flash. The type of input such as thermocouple, resistance bulb, D.C. voltage (current), etc. can be arbitrarily set to 6 channels at the maximum. The data stored in Compact Flash can be regenerated on the screen, and the use of supplied support software allows the data to be regenerated on a PC screen. The data recorded in ASCII format can be directly read in a spreadsheet such as Excel, which facilitates the processing on a PC. (The data recorded in binary format cannot be read in.) Industrials- Oil & Gas

- Pulp & Paper

-

Description This is a paperless recorder that displays measured data on the LCD is real time and stores data in Compact Flash. The type of input such as thermocouple, resistance bulb, D.C. voltage (current), etc. can be arbitrarily set to 18 channels at the maximum. The data stored in Compact Flash can be regenerated on the screen, and the use of supplied support software allows the data to be regenerated on a PC screen. The data recorded in ASCII format can be directly read in a spreadsheet such as Excel, which facilitates the processing on a PC. (The data recorded in binary format cannot be read in.) Industrials

Description This is a paperless recorder that displays measured data on the LCD is real time and stores data in Compact Flash. The type of input such as thermocouple, resistance bulb, D.C. voltage (current), etc. can be arbitrarily set to 18 channels at the maximum. The data stored in Compact Flash can be regenerated on the screen, and the use of supplied support software allows the data to be regenerated on a PC screen. The data recorded in ASCII format can be directly read in a spreadsheet such as Excel, which facilitates the processing on a PC. (The data recorded in binary format cannot be read in.) Industrials- Oil & Gas

- Pulp & Paper

-

Description This is a paperless recorder that displays measured data on the LCD is real time and stores data in Compact Flash. The type of input such as thermocouple, resistance bulb, D.C. voltage (current), etc. can be arbitrarily set to 18 channels at the maximum. The data stored in Compact Flash can be regenerated on the screen, and the use of supplied support software allows the data to be regenerated on a PC screen. The data recorded in ASCII format can be directly read in a spreadsheet such as Excel, which facilitates the processing on a PC. (The data recorded in binary format cannot be read in.) Industrials

Description This is a paperless recorder that displays measured data on the LCD is real time and stores data in Compact Flash. The type of input such as thermocouple, resistance bulb, D.C. voltage (current), etc. can be arbitrarily set to 18 channels at the maximum. The data stored in Compact Flash can be regenerated on the screen, and the use of supplied support software allows the data to be regenerated on a PC screen. The data recorded in ASCII format can be directly read in a spreadsheet such as Excel, which facilitates the processing on a PC. (The data recorded in binary format cannot be read in.) Industrials- Oil & Gas

- Pulp & Paper

-

Description This is a paperless recorder that displays measured data on the LCD is real time and stores data in Compact Flash. The type of input such as thermocouple, resistance bulb, D.C. voltage (current), etc. can be arbitrarily set to 36 channels at the maximum. The data stored in Compact Flash can be regenerated on the screen, and the use of supplied support software allows the data to be regenerated on a PC screen. The data recorded in ASCII format can be directly read in a spreadsheet such as Excel, which facilitates the processing on a PC. (The data recorded in binary format cannot be read in.) Industrials

Description This is a paperless recorder that displays measured data on the LCD is real time and stores data in Compact Flash. The type of input such as thermocouple, resistance bulb, D.C. voltage (current), etc. can be arbitrarily set to 36 channels at the maximum. The data stored in Compact Flash can be regenerated on the screen, and the use of supplied support software allows the data to be regenerated on a PC screen. The data recorded in ASCII format can be directly read in a spreadsheet such as Excel, which facilitates the processing on a PC. (The data recorded in binary format cannot be read in.) Industrials- Oil & Gas

- Pulp & Paper

-

Description FCX-AIII series transmitters are electronic transmitters which use electrostatic capacitance sensors. They feature compact design, high accuracy, and long-term stability, and offer a variety of diaphragm materials. You can select from: type L housing suited to a vertical pipe, type T housing to horizontal pipe, and direct mount type. Industrials

Description FCX-AIII series transmitters are electronic transmitters which use electrostatic capacitance sensors. They feature compact design, high accuracy, and long-term stability, and offer a variety of diaphragm materials. You can select from: type L housing suited to a vertical pipe, type T housing to horizontal pipe, and direct mount type. Industrials- Oil & Gas

- Pulp & Paper

-

Description This water level transmitter is used for measuring the level of clean water, sewage water, well, river, etc. The detector is placed on the bottom of the water, and the water head pressure acting on the pressure receiving diaphragm is detected, converted into a current signal and then transmitted to a receiving instrument via the connector terminal. Industrial

Description This water level transmitter is used for measuring the level of clean water, sewage water, well, river, etc. The detector is placed on the bottom of the water, and the water head pressure acting on the pressure receiving diaphragm is detected, converted into a current signal and then transmitted to a receiving instrument via the connector terminal. Industrial- Oil & Gas

- Pulp & Paper

-

Description The FCX-AIII level transmitter accurately measures liquid level and transmits a proportional 4 to 20 mA signal. The transmitter utilizes a unique micromachined capacitance silicon sensor with state-of-the-art microprocessor technology to provide exceptional performance and functionality. Industrial

Description The FCX-AIII level transmitter accurately measures liquid level and transmits a proportional 4 to 20 mA signal. The transmitter utilizes a unique micromachined capacitance silicon sensor with state-of-the-art microprocessor technology to provide exceptional performance and functionality. Industrial- Oil & Gas

- Pulp & Paper

-

Description DDM-TMA1 (its nick name is Tamaichi) is designed to measure the dust concentration in wet flue gases. The measuring principle of DDM-TMA1 is Non-sampling Light Scattering method. The wet flue gas passes inside of the high performance heater which vanishes the mist in the wet flue gases, and the light scattering dust detector measures just the dust concentration in the wer flue gases. The air curtain prevents the wet flue gas flow around the detection area from interfering with the detection area. DDM-TMA1 can monitor dust concentration even in heavy wet flue gases. Industrials

Description DDM-TMA1 (its nick name is Tamaichi) is designed to measure the dust concentration in wet flue gases. The measuring principle of DDM-TMA1 is Non-sampling Light Scattering method. The wet flue gas passes inside of the high performance heater which vanishes the mist in the wet flue gases, and the light scattering dust detector measures just the dust concentration in the wer flue gases. The air curtain prevents the wet flue gas flow around the detection area from interfering with the detection area. DDM-TMA1 can monitor dust concentration even in heavy wet flue gases. Industrials- Oil & Gas

- Chemical & Petrochemical

- Power

- Steel

- Pulp & Paper

-

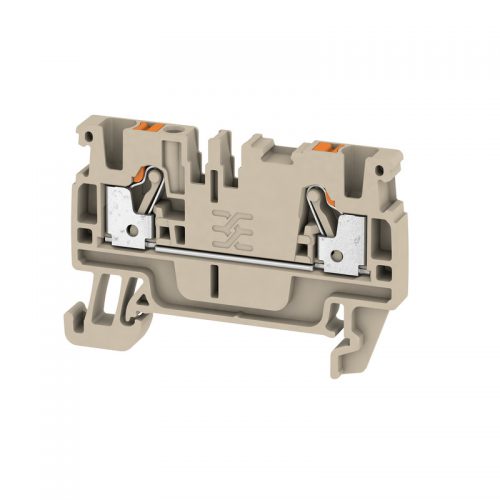

Description Spring connection with PUSH IN Technology. The innovative PUSH IN technology reduces the amount of time you spend on wiring to a minimum. Direct insertion guarantees high conductor pull-out forces and simple handling for all conductor types. Industrial

Description Spring connection with PUSH IN Technology. The innovative PUSH IN technology reduces the amount of time you spend on wiring to a minimum. Direct insertion guarantees high conductor pull-out forces and simple handling for all conductor types. Industrial- Oil & Gas

- Chemical & Petrochemical

- Paper

- Steel

- Pulp & Paper

- Electronic

- Renewable Energy

- Transportation

-

AFS 2.5 CF 2C BK -Fuse terminal, PUSH IN, 2.5 mm², 250 V, 10 A, Black AFS 2.5 CF 2C 12V BK - Fuse terminal, PUSH IN, 2.5 mm², 12 V, 10 A, Black AFS 2.5 CF 2C 24V BK - Fuse terminal, PUSH IN, 2.5 mm², 24 V, 10 A, Black AFS 4 2C BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black AFS 4 2C 10-36V BK - Fuse terminal, PUSH IN, 4 mm², 36 V, 6.3 A, Black AFS 4 2C 30-70V BK - Fuse terminal, PUSH IN, 4 mm², 70 V, 6.3 A, Black AFS 4 2C 100-250V BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black

AFS 2.5 CF 2C BK -Fuse terminal, PUSH IN, 2.5 mm², 250 V, 10 A, Black AFS 2.5 CF 2C 12V BK - Fuse terminal, PUSH IN, 2.5 mm², 12 V, 10 A, Black AFS 2.5 CF 2C 24V BK - Fuse terminal, PUSH IN, 2.5 mm², 24 V, 10 A, Black AFS 4 2C BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black AFS 4 2C 10-36V BK - Fuse terminal, PUSH IN, 4 mm², 36 V, 6.3 A, Black AFS 4 2C 30-70V BK - Fuse terminal, PUSH IN, 4 mm², 70 V, 6.3 A, Black AFS 4 2C 100-250V BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black