-

Stopless Flow Meter This flow meter is connected directly to feeders, conveyors, shutes, and other equipment and used for the precision measurements of flow rates of fine to bulk solids. The capacity ranges from 0 –1 kg/h to 0 –380 t/h. Decription The Stopless Flow Meter is used for measuring powders and other substanes as with the hopper scale, but differs from the hopper scale in that it is provided with two scale hoppers which permit substances to be charged into the system continuously for substance to be charged into the system continuously for measurements. Also, its installation space is reduced substantially as shown in the diagrams below, and there is no generation of zero drift due to inner dust, as contrated with the hopper scale. Related Market 1. Petrochemical 2. Coal Fire Power 3. Steel 4. Pulp & Paper

Stopless Flow Meter This flow meter is connected directly to feeders, conveyors, shutes, and other equipment and used for the precision measurements of flow rates of fine to bulk solids. The capacity ranges from 0 –1 kg/h to 0 –380 t/h. Decription The Stopless Flow Meter is used for measuring powders and other substanes as with the hopper scale, but differs from the hopper scale in that it is provided with two scale hoppers which permit substances to be charged into the system continuously for substance to be charged into the system continuously for measurements. Also, its installation space is reduced substantially as shown in the diagrams below, and there is no generation of zero drift due to inner dust, as contrated with the hopper scale. Related Market 1. Petrochemical 2. Coal Fire Power 3. Steel 4. Pulp & Paper -

Powder and Bulk Solids Flowmeter When a pukverized material charged from a leader falls naturaly from a fixed height the horizonal component of the impact force exerted on the sensing plate will be proportioner to the instantaneous weight flow of the material. This is the basic principle of operation of the impactline Flowmeter. Related Market 1. Petrochemical 2. Coal fire Power 3. Steel 4. Pulp & Paper

Powder and Bulk Solids Flowmeter When a pukverized material charged from a leader falls naturaly from a fixed height the horizonal component of the impact force exerted on the sensing plate will be proportioner to the instantaneous weight flow of the material. This is the basic principle of operation of the impactline Flowmeter. Related Market 1. Petrochemical 2. Coal fire Power 3. Steel 4. Pulp & Paper -

Impactline Flowmeter When a pukverized material charged from a leader falls naturaly from a fixed height the horizonal component of the impact force exerted on the sensing plate will be proportioner to the instantaneous weight flow of the material. This is the basic principle of operation of the impactline Flowmeter. Related Market 1. Petrochemical 2. Coal fire Power 3. Steel 4. Pulp & Paper

Impactline Flowmeter When a pukverized material charged from a leader falls naturaly from a fixed height the horizonal component of the impact force exerted on the sensing plate will be proportioner to the instantaneous weight flow of the material. This is the basic principle of operation of the impactline Flowmeter. Related Market 1. Petrochemical 2. Coal fire Power 3. Steel 4. Pulp & Paper -

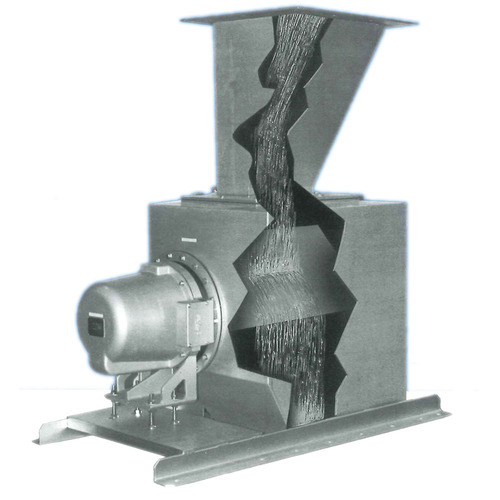

Impact Feeder Convenient, inexpensive precision feeder for bulk solids, whose accuracy is not influenced by changes in the substance’s characteristics. The capacity ranges from 0-3 t/h to 0-60 t/h Description

Impact Feeder Convenient, inexpensive precision feeder for bulk solids, whose accuracy is not influenced by changes in the substance’s characteristics. The capacity ranges from 0-3 t/h to 0-60 t/h Description- The impact Feeder is installed at the hopper's discharge outlet.

- The grain discharged from the hopper is passed through the gate incorprated in the feeder and flows down along the snesing plate.

- The load generated on the sensing plate is converted into an electric signal corresponding to the flow rate by the load cell.

- Based on the control signal, the gate is driven by a built-in motor to control the grain to it's target flow rate.