-

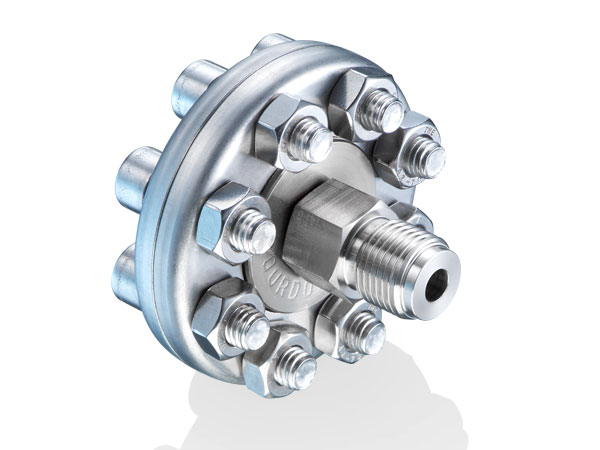

· Size mm. : 63 · For corrosive gasses and liquids · Class 1.6 according to EN 837-1 · Wetted parts: Stainless steel · Case with crimped bezel ring · Lloyds Register Approval · Option: Liquid-filled for applications with pulsations or vibrations · Option: Case material 1.4404 (316L) for aggressive atmosphere

· Size mm. : 63 · For corrosive gasses and liquids · Class 1.6 according to EN 837-1 · Wetted parts: Stainless steel · Case with crimped bezel ring · Lloyds Register Approval · Option: Liquid-filled for applications with pulsations or vibrations · Option: Case material 1.4404 (316L) for aggressive atmosphere -

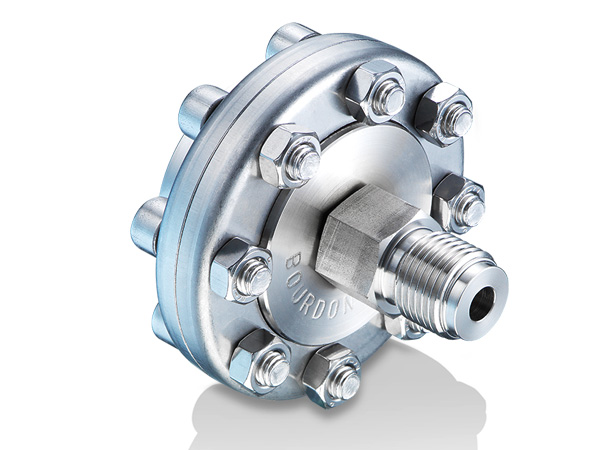

· Size mm. : 63 · For corrosive gasses and liquids · Class 1.6 according to EN 837-1 · Wetted parts Stainless steel (MEX) or Monel (MEM) · Lloyd`s Register approval · Option : liquid-filled for applications with pulsations or vibrations · Option : case material 1.4404 (316L) for aggressive atmosphere

· Size mm. : 63 · For corrosive gasses and liquids · Class 1.6 according to EN 837-1 · Wetted parts Stainless steel (MEX) or Monel (MEM) · Lloyd`s Register approval · Option : liquid-filled for applications with pulsations or vibrations · Option : case material 1.4404 (316L) for aggressive atmosphere -

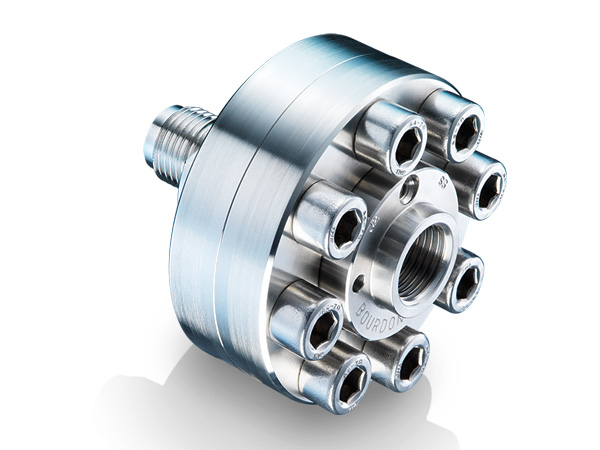

- Series: MEP5 - Size 100 mm - For corrosive gasses and liquids - Class 1 according to EN 837-1 - Wetted parts Stainless steel (MEP) or Monel (MMN) - Lloyds Register Approval - Safety version S3 according to EN 837-1 - Option : liquid-filled for applications with pulsations or vibrations - Option : case material 1.4404 (316L) for aggressive atmosphere

- Series: MEP5 - Size 100 mm - For corrosive gasses and liquids - Class 1 according to EN 837-1 - Wetted parts Stainless steel (MEP) or Monel (MMN) - Lloyds Register Approval - Safety version S3 according to EN 837-1 - Option : liquid-filled for applications with pulsations or vibrations - Option : case material 1.4404 (316L) for aggressive atmosphere -

- Series: MMN5 - Size 100 mm - For corrosive gasses and liquids - Class 1 according to EN 837-1 - Wetted parts Stainless steel (MEP) or Monel (MMN) - Lloyds Register Approval - Safety version S3 according to EN 837-1 - Option : liquid-filled for applications with pulsations or vibrations - Option : case material 1.4404 (316L) for aggressive atmosphere

- Series: MMN5 - Size 100 mm - For corrosive gasses and liquids - Class 1 according to EN 837-1 - Wetted parts Stainless steel (MEP) or Monel (MMN) - Lloyds Register Approval - Safety version S3 according to EN 837-1 - Option : liquid-filled for applications with pulsations or vibrations - Option : case material 1.4404 (316L) for aggressive atmosphere -

Pressure gauge with contact Series: MG5 (With inductive contact) Size 100 mm - For corrosive gasses and liquids - Class 1 according to EN 837-1 - Inductive contacts with sensor according to EN 60947-5-6 (NAMUR) - Option : liquid-filled for applications with pulsations or vibrations - Option: case material 1.4404 (316L) for aggressive atmosphere

Pressure gauge with contact Series: MG5 (With inductive contact) Size 100 mm - For corrosive gasses and liquids - Class 1 according to EN 837-1 - Inductive contacts with sensor according to EN 60947-5-6 (NAMUR) - Option : liquid-filled for applications with pulsations or vibrations - Option: case material 1.4404 (316L) for aggressive atmosphere -

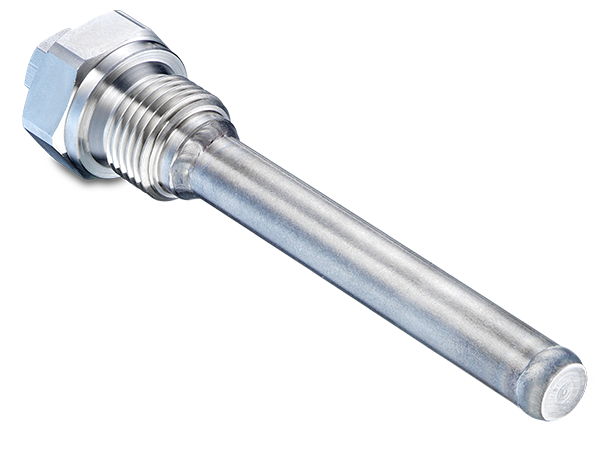

Thermowells Series: T8416, T8916, T9144, T9357 (Welded connection) Series: T8410, T8911, T9093, T9143, T9346 (Screwed connection) Size Max. 250 bar - 360° positioning of the thermometer dial - For thermometers with smooth immersion tube without process connection - Welded or threaded - Brass, steel & stainless steel (1.4571 / 316Ti)

Thermowells Series: T8416, T8916, T9144, T9357 (Welded connection) Series: T8410, T8911, T9093, T9143, T9346 (Screwed connection) Size Max. 250 bar - 360° positioning of the thermometer dial - For thermometers with smooth immersion tube without process connection - Welded or threaded - Brass, steel & stainless steel (1.4571 / 316Ti) -

Gas filled thermometer Series: TSFE (Remote measurement with contact) Size 100, 160 mm. - For corrosive gasses and liquids - Class 1 according to EN 13190 - Capillary 0.5 to 30 m - Mechanical or inductive contacts - Wetted parts and case material stainless steel - Option : case material 1.4404 (316L) for aggressive atmosphere

Gas filled thermometer Series: TSFE (Remote measurement with contact) Size 100, 160 mm. - For corrosive gasses and liquids - Class 1 according to EN 13190 - Capillary 0.5 to 30 m - Mechanical or inductive contacts - Wetted parts and case material stainless steel - Option : case material 1.4404 (316L) for aggressive atmosphere -

Features Size 2" to 72" (50 mm to 1800 mm) ASME Class Class 150 to 2500 Design Standard API 600, API 603, ASME B 16.34 Special Features & Benefit Gate Valve design complies to API 600, Edition 13 Offered with API 600 monogram Fugitive Emissions - Complies to API 624 and ISO 15848-1 (<50 ppm / Class AH leakage levels, optional) Gate Valves tested to API 624 at Yarmouth Research Lab, Maine, USA Body gasket leakage <100 ppm observed on eight sizes tested as per API 624 Annexure A Fire Safe - By design and tested to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design Examination Certificate (certified by DNV) available Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL 3 Safety Integrity Level for Automated Valves Gate valves successfully tested to Shell Design Validation Test Procedure 77/300 and witnessed by Shell Inspectors Robust stem-wedge design connection successfully tested as per API RP 591 Annex B Hardfaced body guides and wedge slots (sizes >24”) Inconel overlay/ cladded options offered

Features Size 2" to 72" (50 mm to 1800 mm) ASME Class Class 150 to 2500 Design Standard API 600, API 603, ASME B 16.34 Special Features & Benefit Gate Valve design complies to API 600, Edition 13 Offered with API 600 monogram Fugitive Emissions - Complies to API 624 and ISO 15848-1 (<50 ppm / Class AH leakage levels, optional) Gate Valves tested to API 624 at Yarmouth Research Lab, Maine, USA Body gasket leakage <100 ppm observed on eight sizes tested as per API 624 Annexure A Fire Safe - By design and tested to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design Examination Certificate (certified by DNV) available Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL 3 Safety Integrity Level for Automated Valves Gate valves successfully tested to Shell Design Validation Test Procedure 77/300 and witnessed by Shell Inspectors Robust stem-wedge design connection successfully tested as per API RP 591 Annex B Hardfaced body guides and wedge slots (sizes >24”) Inconel overlay/ cladded options offered -

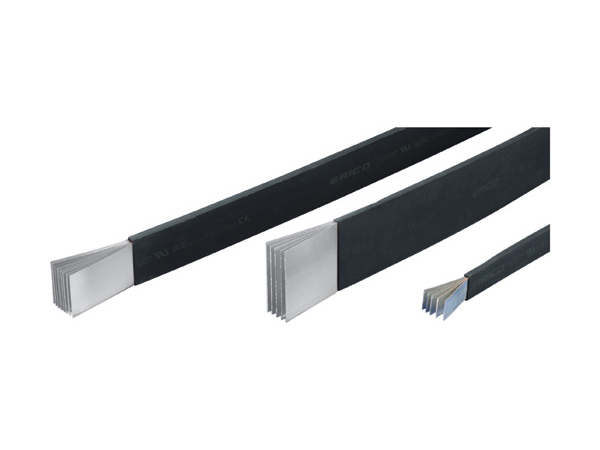

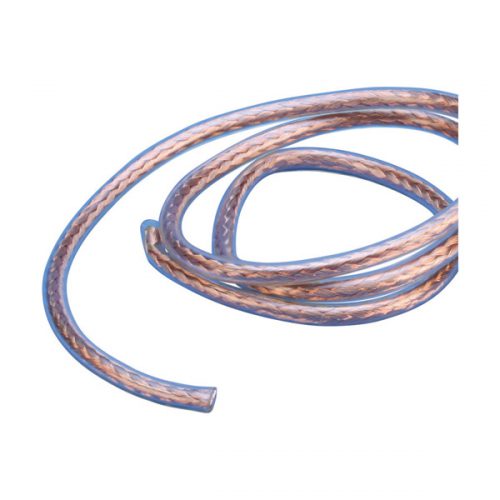

Features IBS Advanced Round Insulated Braided Conductor, Halogen Free

Features IBS Advanced Round Insulated Braided Conductor, Halogen Free- Resistant to vibration, improving reliability and performance

- Insulated by high-resistance, halogen free, flame retardant and low smoke material

- Tinned copper provides superior corrosion resistance• Improves assembly flexibility and aesthetics

- Quick and easy installation

- No additional cutting, stripping, crimping and punching needed

- Conforms to NF EN 45545 obtaining an HL2 classification for chapters R22 and R23

- Small wire diameter provides maximum flexibility

- Dramatically smaller and more flexible than comparable cable based on ampacity

- Better power density than cable with lower skin effect ratio

- Reduces total installation cost

- RoHS compliant

- Suitable for all main molded case circuit breakers

- Resistant to vibration, improving reliability and performance

- Insulated by high-resistance, halogen free, flame retardant and low smoke material

- Tinned copper provides superior corrosion resistance

- Improves assembly flexibility and aesthetics

- Quick and easy installation

- No additional cutting, stripping, crimping and punching needed

- Integral palm without lugs or terminals reduces material and assembly weight

- Conforms to NF EN 45545 obtaining an HL2 classification for chapters R22 and R23

- DNV GL® and Bureau Veritas certified for marine and offshore applications

- Small wire diameter provides maximum flexibility

- Dramatically smaller and more flexible than comparable cable based on ampacity

- Better power density than cable with lower skin effect ratio

- Reduces total installation cost

- RoHS compliant

- Tinned copper allows for copper or aluminum conductor connections

- Suitable for all main 125/160 A electrical devices and specifically molded case circuit breakers

- Resistant to vibration, improving reliability and performance

- Improves assembly flexibility and aesthetics

- Quick and easy installation

- No additional cutting, stripping, crimping and punching needed

- Small wire diameter provides maximum flexibility

- Halogen free solution for applications requiring a low smoke solution

- Conforms to NF EN 45545 obtaining an HL2 classification for chapters R22 and R23

- DNV GL® certified for marine and offshore applications

- High working temperature

- RoHS compliant

-

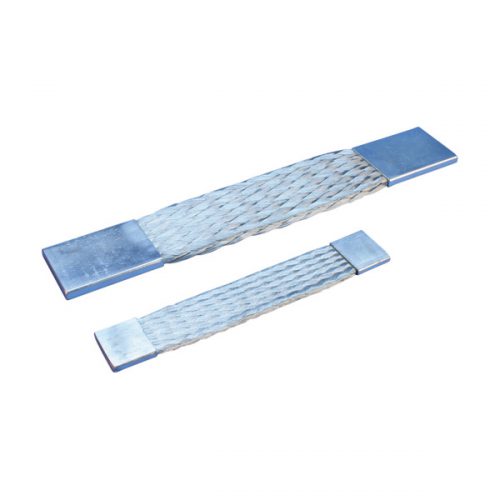

Features PBC Braided Power Shunt

Features PBC Braided Power Shunt- Ideal for transformer-busduct link

- Solid palms can be drilled to fit customer specific designs

- Extra flexible power connection and good resistance to vibration

- Press welded laminations are welded to each other through direct current applied to pieces under pressure

- Press welding forms a solid palm with the properties of a plain bar

- Smaller cross section for same capacity

- Runs cooler than equal section

-

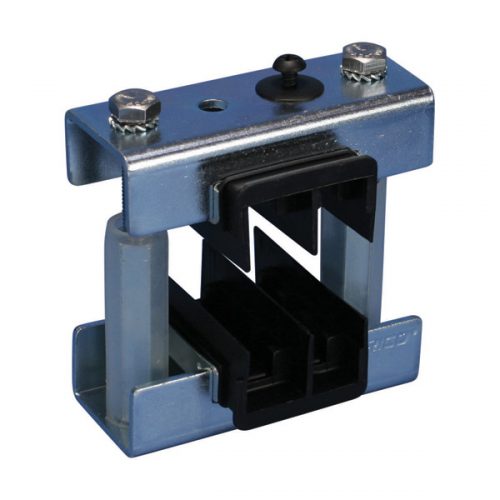

Features HCBC High Current Busbar Clamp

Features HCBC High Current Busbar Clamp- Connects copper busbar to copper busbar, nVent ERIFLEX Flexibar or power shunt

- Made with non-magnetic materials for high current connections between nVent ERIFLEX Flexibar and rigid busbars such as transformer terminals

- Rigid design assures even contact pressure

- Installs quickly and easily

- Ideal for on site modifications

- RoHS compliant

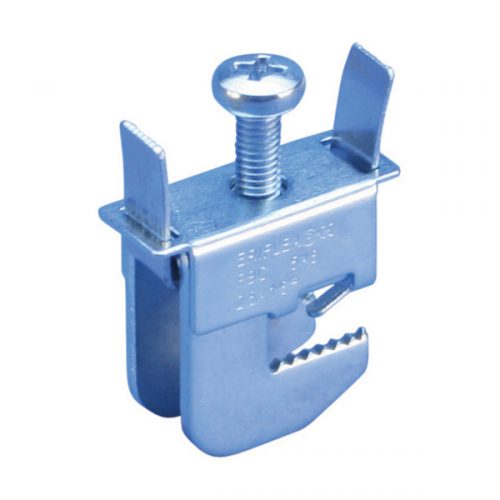

- Very compact clamp for connecting cable conductors or nVent ERIFLEX Flexibar to busbar without drilling

- Conductor is clamped with a pressure plate

- Clamps can be mounted and slid into position on busbar prior to connecting conductors

- Connections can be added after busbar has been mounted

- Single screw locks clamp and makes connection

- EAC compliant

- RoHS compliant

- Connects nVent ERIFLEX Flexibar to punched busbar

- Allows for excellent electrical contact

- Compact, space saving design

- Installs quickly and easily

- Ideal for on site modifications

- Connects two copper busbars together or nVent ERIFLEX Flexibar to copper busbar

- Two ribbed plates complete with screws

- Allows for excellent electrical contact

- Installs quickly and easily

- Ideal for on site modifications

- RoHS complian

- Connects nVent ERIFLEX Flexibar to copper busbar

- Two plates complete with screws

- Allows for excellent electrical contact

- Installs quickly and easily

- Ideal for on site modifications

- RoHS compliant

-

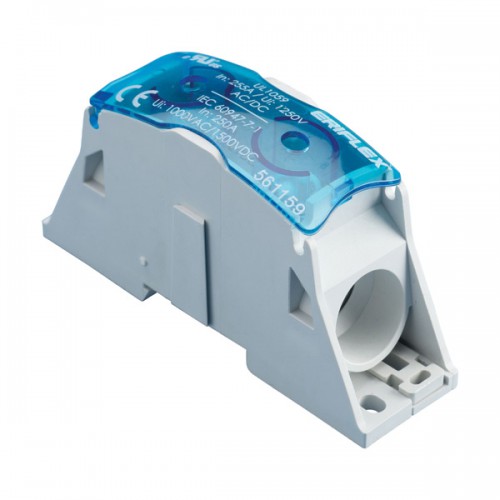

nVent ERIFLEX offers a wide selection of compact halogen free single pole, two pole, and four pole distribution blocks and a complete range of assembly support products for easy fastening to DIN rails or steel sheet. The blocks offer easy assembly with visual inspection to allow for confirmation of connections to a wide range of conductors including nVent ERIFLEX Flexibar Advanced and IBS/IBSB Advanced. The high fill ratio ensures optimal electrical connectivity even in tight assemblies. Features UD-80A Single Pole Distribution Block

nVent ERIFLEX offers a wide selection of compact halogen free single pole, two pole, and four pole distribution blocks and a complete range of assembly support products for easy fastening to DIN rails or steel sheet. The blocks offer easy assembly with visual inspection to allow for confirmation of connections to a wide range of conductors including nVent ERIFLEX Flexibar Advanced and IBS/IBSB Advanced. The high fill ratio ensures optimal electrical connectivity even in tight assemblies. Features UD-80A Single Pole Distribution Block- Increase the number of outputs with one input using a jumper wire

- Tinned copper block allows for copper or aluminum conductor connections

- Screw retaining cover is hinged and removable

- Design allows for visual inspection of conductor and confirmation of connection

- Modular snap-together blocks for building multi-pole power blocks

- Easily clips onto DIN rail or mounts to panel with screws

- 95% fill ratio

- Halogen free

- RoHS compliant

- Increase the number of outputs with one input using a jumper

- Tinned copper block allows for copper or aluminum conductor connections

- Screw retaining cover is hinged and removable

- Design allows for visual inspection of conductor and confirmation of connection

- Modular snap-together blocks for building multi-pole power blocks

- Easily clips onto DIN rail or mounts to panel with screws

- 95% fill ratio

- Halogen free

- RoHS compliant

- Increase the number of outputs with one input using a jumper

- Tinned copper block allows for copper or aluminum conductor connections

- Screw retaining cover is hinged and removable

- Design allows for visual inspection of conductor and confirmation of connection

- Modular snap-together blocks for building multi-pole power blocks

- Easily clips onto DIN rail or mounts to panel with screws

- 95% fill ratio

- Halogen free

- RoHS complian

- Connects nVent ERIFLEX Flexibar on line side using FLG-250 Flat Terminal Connection

- Tinned copper block allows for copper or aluminum conductor connections

- Screw retaining cover is hinged and removable

- Design allows for visual inspection of conductor and confirmation of connection

- Modular snap-together blocks for building multi-pole power blocks

- Easily clips onto DIN rail or mounts to panel with screws

- 95% fill ratio

- Halogen free

- RoHS compliant

- Connects nVent ERIFLEX Flexibar on line side using FLG-400 Flat Terminal Connection

- Tinned copper block allows for copper or aluminum conductor connections

- Screw retaining cover is hinged and removable

- Design allows for visual inspection of conductor and confirmation of connection

- Modular snap-together blocks for building multi-pole power blocks

- Easily clips onto DIN rail or mounts to panel with screws

- 95% fill ratio

- Halogen free

- RoHS compliant

- Ideal for solar applications

- Tinned aluminium block allows for copper or aluminum cable

- Screw retaining cover is hinged and removable

- Design allows for visual inspection of conductor and confirmation of connection

- Modular snap-together blocks for building multi-pole power blocks

- Easily clips onto DIN rail or mounts to panel with screws

- 95% fill ratio

- Halogen free

- RoHS compliant

- Ideal for solar applications

- Tinned copper block allows for copper or aluminum conductor connections

- Screw retaining cover is hinged and removable

- Design allows for visual inspection of conductor and confirmation of connection

- Modular snap-together blocks for building multi-pole power blocks

- Easily clips onto DIN rail or mounts to panel with screws

- 95% fill ratio

- Halogen free

- RoHS compliant

- Ideal for solar applications

- Increase the number of outputs with one input using a jumper

- Tinned aluminium block allows for copper or aluminum cable

- Screw retaining cover is hinged and removable

- Design allows for visual inspection of conductor and confirmation of connection

- Easily clips onto DIN rail or mounts to panel with screws

- 95% fill ratio

- Halogen free

- RoHS compliant

- Ideal for solar applications

- Increase the number of outputs with one input using a jumper

- Tinned copper block allows for copper or aluminum conductor connections

- Screw retaining cover is hinged and removable

- Design allows for visual inspection of conductor and confirmation of connection

- Easily clips onto DIN rail or mounts to panel with screws

- 95% fill ratio

- Halogen free

- RoHS compliant

- Directly connect nVent ERIFLEX Flexibar on line side

- Tinned copper block allows for copper or aluminum conductor connections

- Screw retaining cover is hinged and removable

- Design allows for visual inspection of conductor and confirmation of connection

- Modular snap-together blocks for building multi-pole power blocks

- Easily clips onto DIN rail or mounts to panel with screws

- 95% fill ratio

- Halogen free

- RoHS compliant

- Connects nVent ERIFLEX Flexibar or IBSB/IBSBR Power Braid to UD-250A/400A Single Pole Distribution Block

- Provides direct link between blocks and switch or circuit breakers

-

Features BD Two Pole Distribution Block

Features BD Two Pole Distribution Block- Minimum space for maximum power

- Protection cover and insulating screens are transparent

- Insulating screen between each row

- Easy and safe connections

- Easily clips onto DIN rail or mounts to panel with screws

- Halogen free

- RoHS compliant

-

Features TD Compact Four Pole Distribution Block

Features TD Compact Four Pole Distribution Block- Minimum space for maximum power

- Protection cover and insulating screens are transparent

- Insulating screen between each row

- Easy and safe connections

- Easily clips onto DIN rail or mounts to panel with screws

- Solid bars provide reliability

- Wiring with or without terminal

- Halogen free

- RoHS compliant

- Connect nVent ERIFLEX Flexibar, insulated braided conductor or cable with lug on line side

- Tinned copper bars allows for copper or aluminum cable

- Transparent protection covers

- Easy and safe connections

- Easily clips onto DIN rail or mounts to panel with screws

- Solid bars provide reliability

- Input separated from outputs

- Supports wiring from both sides

- Design allows for visual inspection of conductor and confirmation of connection

- Large end terminals

- High percentange of fill ratio

- Wiring with or without terminal

- Halogen free

- RoHS compliant

- Attaches to four pole distribution blocks for increased wire capacity

- Direct electrical connection

- Strong mechanical assembly

- Transparent protection cover

- Halogen free

- RoHS compliant

-

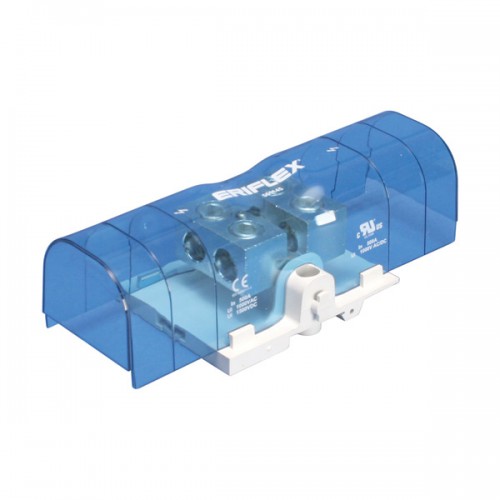

nVent ERIFLEX Power Blocks are the main DIN mounted output/input devices for connection between primary and secondary switchboard, or main input/output connection for machine or industrial equipment (such as invertor, air conditioning machines, etc.). The high short circuit rated large cross section blocks offer time savings and reliability in every panel configuration. The complete Power Blocks range offers multiple connection types with up to four cables, nVent ERIFLEX Flexibar Advanced, or IBS/IBSB Advanced power braids. Features

nVent ERIFLEX Power Blocks are the main DIN mounted output/input devices for connection between primary and secondary switchboard, or main input/output connection for machine or industrial equipment (such as invertor, air conditioning machines, etc.). The high short circuit rated large cross section blocks offer time savings and reliability in every panel configuration. The complete Power Blocks range offers multiple connection types with up to four cables, nVent ERIFLEX Flexibar Advanced, or IBS/IBSB Advanced power braids. Features- Can be connected with round cross section cable or flat connection system like nVent ERIFLEX Flexibar Advanced or IBS/IBSB Advanced Insulated Braided Conductor

- Compact power block with high short circuit current rating

- Tinned copper or aluminum block allows for copper or aluminum conductor direct connections, or using ferrule

- Screw retaining cover is hinged and removable

- Design allows for visual inspection of conductor and confirmation of connection

- Modular snap-together blocks for building multi-pole power blocks

- Easily clips onto DIN rail or mounts to panel with screws

- Voltage detection and measurement connection

- 95% fill ratio

- Halogen free

- RoHS compliant

-

nVent ERICO offers a wide range of halogen free lug-to-lug, lug-to-tunnel, and tunnel-to-tunnel power terminals and fixing assemblies. The tinned copper block design allows for connections using copper or aluminum conductors while the accessible tunnels and studs allow for easy connections that can be visually inspected through the adjustable finger safe transparent cover. Conveniently gangable to allow for the construction of multi-pole power blocks, the power terminals are easily mounted onto DIN rails or directly to the panel itself using screws. Features Lug-to-Lug Power Terminals (SBLL 250, 500, 800)

nVent ERICO offers a wide range of halogen free lug-to-lug, lug-to-tunnel, and tunnel-to-tunnel power terminals and fixing assemblies. The tinned copper block design allows for connections using copper or aluminum conductors while the accessible tunnels and studs allow for easy connections that can be visually inspected through the adjustable finger safe transparent cover. Conveniently gangable to allow for the construction of multi-pole power blocks, the power terminals are easily mounted onto DIN rails or directly to the panel itself using screws. Features Lug-to-Lug Power Terminals (SBLL 250, 500, 800)- Tinned copper block allows for copper or aluminum conductor connections

- Accessible studs allow for easy connection of sections of nVent ERIFLEX Flexibar or other conductors

- Design allows for visual inspection of conductor and confirmation of connection

- Adjustable transparent cover

- Modular snap-together blocks for building multi-pole power blocks

- Easily clips onto DIN rail or mounts to panel with screws

- SBLEC Power Terminals Fixing Accessory required for direct panel mount

- Halogen free

- RoHS compliant

- Tinned copper block allows for copper or aluminum conductor connections

- Accessible studs and tunnels allow for easy connection of nVent ERIFLEX Flexibar and other conductors

- Design allows for visual inspection of conductor and confirmation of connection

- Voltage detection and measurement connection

- Adjustable transparent cover

- Modular snap-together blocks for building multi-pole power blocks

- Easily clips onto DIN rail or mounts to panel with screws

- SBLEC Power Terminals Fixing Accessory required for direct panel mount

- Halogen free

- RoHS compliant

- Tinned copper block allows for copper or aluminum conductor connections

- Accessible tunnels allow for easy connection of wire

- Design allows for visual inspection of conductor and confirmation of connection

- Adjustable transparent cover

- Modular snap-together blocks for building multi-pole power blocks

- Easily clips onto DIN rail or mounts to panel with screws

- SBLEC Power Terminals Fixing Accessory required for direct panel mount

- Halogen free

- RoHS compliant

- Attach power terminal fixing accessory to back of power terminals for direct panel mounting or DIN rail end cap mounting

- Easily clips onto DIN rail or mounts to panel with screws

- Halogen free

-

Special Features & Benefits Gate Valve design complies to API 600, Edition 13 Offered with API 600 monogram Fugitive Emissions - Complies to API 624 and ISO 15848-1 (<50 ppm / Class AH leakage levels, optional) Gate Valves tested to API 624 at Yarmouth Research Lab, Maine, USA Body gasket leakage <100 ppm observed on eight sizes tested as per API 624 Annexure A Fire Safe - By design and tested to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design Examination Certificate (certified by DNV) available ATEX - Meets requirements of ATEX Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL 3 Safety Integrity Level certificatation is available Gate valves successfully tested to Shell Design Validation Test Procedure 77/300 and witnessed by Shell Inspectors Robust stem-wedge design connection successfully tested as per API RP 591 Annex B Hardfaced body guides and wedge slots (sizes >24”) Inconel overlay/ cladded options offered

Special Features & Benefits Gate Valve design complies to API 600, Edition 13 Offered with API 600 monogram Fugitive Emissions - Complies to API 624 and ISO 15848-1 (<50 ppm / Class AH leakage levels, optional) Gate Valves tested to API 624 at Yarmouth Research Lab, Maine, USA Body gasket leakage <100 ppm observed on eight sizes tested as per API 624 Annexure A Fire Safe - By design and tested to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design Examination Certificate (certified by DNV) available ATEX - Meets requirements of ATEX Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL 3 Safety Integrity Level certificatation is available Gate valves successfully tested to Shell Design Validation Test Procedure 77/300 and witnessed by Shell Inspectors Robust stem-wedge design connection successfully tested as per API RP 591 Annex B Hardfaced body guides and wedge slots (sizes >24”) Inconel overlay/ cladded options offered -

Globe Valves

Globe Valves- Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures.

- In-situ hardfaced seat design for all sizes

- Higher hardfacing thickness (3 mm) to ensure consistent hot hardness

- Body-guided Disc offered in all sizes/classes to provide disc stability and avoids vibration of the disc-disc nut assembly. Disc guides hardfaced for longer life

-

Check Valves

Check Valves- Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures. Customised deposition process in F91/ C12A valves to avoid delamination of hardfaced surfaces Live loading of bonnet bolts for F91/ C12A valves

-

Special Features & Benefits

Fugitive Emissions - Complies to ISO 15848-1: 2006 Class AH leakage

SIL3 Safety Integrity Level for Automated Valves

The bellows lifecycle is designed as per MSS SP-117

Metal bellows seal the moving stem and increase durability of packed stem seal valves

Bellow provide a barrier between the stem at its point of entry through the pressure boundary and the process fluid within the valve, to eliminate stem leakage

An anti-rotation device is provided in the bonnet to ensure bellow does not get twisted during assembly and disassembly or by vibration

Bellow-sealed valves are usually leak tested using a mass spectrometer to detect leakage rates below 1x10E-06 std.cc/sec.

Bellow-sealed bonnets are backed up with a standard stem packing set and a leakage monitoring port between the bellows and the packing in order to prevent catastrophic release of hazardous fluid in the event of a bellows leak.

Special Features & Benefits

Fugitive Emissions - Complies to ISO 15848-1: 2006 Class AH leakage

SIL3 Safety Integrity Level for Automated Valves

The bellows lifecycle is designed as per MSS SP-117

Metal bellows seal the moving stem and increase durability of packed stem seal valves

Bellow provide a barrier between the stem at its point of entry through the pressure boundary and the process fluid within the valve, to eliminate stem leakage

An anti-rotation device is provided in the bonnet to ensure bellow does not get twisted during assembly and disassembly or by vibration

Bellow-sealed valves are usually leak tested using a mass spectrometer to detect leakage rates below 1x10E-06 std.cc/sec.

Bellow-sealed bonnets are backed up with a standard stem packing set and a leakage monitoring port between the bellows and the packing in order to prevent catastrophic release of hazardous fluid in the event of a bellows leak. -

Special Features & Benefits Pressure-seal Gate Valve design conforms to ASME B 16.34. The design was successfully validated by conducting in-house High Pressure High Temperature (HPHT) Gas Tests on ultra-high pressure valve prototypes. Flow Interruption Test successfully conducted on 8" Class 600 Pressure-seal Gate Valve suitable for Main Stream Isolation Valve (MSIV) service in nuclear power plants - at Areva, Germany. Fugitive Emission - 14" Class 2500 Pressure-seal Gate Valve (test pressure of 431 bar at ambient and 289 bar at 400 degree C) has been tested successfully as per ISO 15848-1, endurance Class CO2 and Tightness Class BH CE Marking – Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL3 Safety Integrity Level for Automated Valves Pressure-seal Gate Valves (up to Class 2500) used in Oil & Gas industry tested to ISO 15848-1 Class BH Pressure-seal Gate Valves successfully tested to Shell Design Validation Test 77/300 and witnessed by Shell Inspectors Valves in intermediate classes reduce total cost of ownership Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures. Higher hardfacing thickness (3 mm) to ensure consistent hot hardness Disc guides hardfaced for longer life Customised deposition process in F91/ C12A valves to avoid delamination of hardfaced surfaces Live loading of bonnet bolts for F91/ C12A valves Special high purity graphite packing (seven rings) provided for pressure rating > Class 2500 in Power applications Live loading of bonnet bolts and gland bolts for all valves in F91/ C12A construction

Special Features & Benefits Pressure-seal Gate Valve design conforms to ASME B 16.34. The design was successfully validated by conducting in-house High Pressure High Temperature (HPHT) Gas Tests on ultra-high pressure valve prototypes. Flow Interruption Test successfully conducted on 8" Class 600 Pressure-seal Gate Valve suitable for Main Stream Isolation Valve (MSIV) service in nuclear power plants - at Areva, Germany. Fugitive Emission - 14" Class 2500 Pressure-seal Gate Valve (test pressure of 431 bar at ambient and 289 bar at 400 degree C) has been tested successfully as per ISO 15848-1, endurance Class CO2 and Tightness Class BH CE Marking – Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL3 Safety Integrity Level for Automated Valves Pressure-seal Gate Valves (up to Class 2500) used in Oil & Gas industry tested to ISO 15848-1 Class BH Pressure-seal Gate Valves successfully tested to Shell Design Validation Test 77/300 and witnessed by Shell Inspectors Valves in intermediate classes reduce total cost of ownership Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures. Higher hardfacing thickness (3 mm) to ensure consistent hot hardness Disc guides hardfaced for longer life Customised deposition process in F91/ C12A valves to avoid delamination of hardfaced surfaces Live loading of bonnet bolts for F91/ C12A valves Special high purity graphite packing (seven rings) provided for pressure rating > Class 2500 in Power applications Live loading of bonnet bolts and gland bolts for all valves in F91/ C12A construction -

Special Features & Benefits Pressure-seal Globe Valve design conforms to ASME B 16.34. CE Marking – Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment Safety Integrity Level for Automated Valves - SIL 3 certification available Pressure-seal Globe Valves (up to Class 2500) used in Oil & Gas industry tested to ISO 15848-1 Class BH Pressure-seal Globe Valves successfully tested to Shell Design Validation Test 77/300 and witnessed by Shell Inspectors Valves in intermediate classes reduce total cost of ownership Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures. In-situ hardfaced seat design for all sizes Higher hardfacing thickness (3 mm) to ensure consistent hot hardness Body-guided Disc offered in Pressure-seal Globe Valves (all sizes/classes) provides disc stability and avoids vibration of the disc-disc nut assembly Disc guides hardfaced for longer life Customised deposition process in F91/ C12A valves to avoid delamination of hardfaced surfaces Live loading of bonnet bolts for F91/ C12A valves Special high purity graphite packing (seven rings) provided for pressure rating > Class 2500 in Power applications

Special Features & Benefits Pressure-seal Globe Valve design conforms to ASME B 16.34. CE Marking – Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment Safety Integrity Level for Automated Valves - SIL 3 certification available Pressure-seal Globe Valves (up to Class 2500) used in Oil & Gas industry tested to ISO 15848-1 Class BH Pressure-seal Globe Valves successfully tested to Shell Design Validation Test 77/300 and witnessed by Shell Inspectors Valves in intermediate classes reduce total cost of ownership Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures. In-situ hardfaced seat design for all sizes Higher hardfacing thickness (3 mm) to ensure consistent hot hardness Body-guided Disc offered in Pressure-seal Globe Valves (all sizes/classes) provides disc stability and avoids vibration of the disc-disc nut assembly Disc guides hardfaced for longer life Customised deposition process in F91/ C12A valves to avoid delamination of hardfaced surfaces Live loading of bonnet bolts for F91/ C12A valves Special high purity graphite packing (seven rings) provided for pressure rating > Class 2500 in Power applications -

Special Features & Benefits Pressure-seal Check Valve conforms to ASME B 16.34. CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment Safety Integrity Level for Automated Valves - SIL 3 certification available Valves in intermediate reduce cost of ownership Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures. Higher hardfacing thickness (3 mm) to ensure consistent hot hardness Customised deposition process in F91/ C12A valves to avoid delamination of hardfaced surfaces Live loading of bonnet bolts for F91/ C12A valves

Special Features & Benefits Pressure-seal Check Valve conforms to ASME B 16.34. CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment Safety Integrity Level for Automated Valves - SIL 3 certification available Valves in intermediate reduce cost of ownership Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures. Higher hardfacing thickness (3 mm) to ensure consistent hot hardness Customised deposition process in F91/ C12A valves to avoid delamination of hardfaced surfaces Live loading of bonnet bolts for F91/ C12A valves -

L&T Valves Limited Trunnion Mounted Ball Valves are of 2-piece / 3-piece design, with flanged or butt-weld ends. As a standard, the valves are manufactured in bolted body designs, where the joint between the body and the connector is bolted. The bolted body design offers flexibility for dismantling during field service in case of an emergency. Welded body designs, where the joint between the body and connector is welded, are also available on request Features Trunnion-mounted Ball Valves Size 2" to 56" | ASME Class Class 150 to 2500 API 6D | API 608 2 Piece/3 Piece Construction | Full/Reduced bore Side Entry & Top Entry | Soft Seat & Metal seat Bolted & Welded | Flanged & Buttweld Design

L&T Valves Limited Trunnion Mounted Ball Valves are of 2-piece / 3-piece design, with flanged or butt-weld ends. As a standard, the valves are manufactured in bolted body designs, where the joint between the body and the connector is bolted. The bolted body design offers flexibility for dismantling during field service in case of an emergency. Welded body designs, where the joint between the body and connector is welded, are also available on request Features Trunnion-mounted Ball Valves Size 2" to 56" | ASME Class Class 150 to 2500 API 6D | API 608 2 Piece/3 Piece Construction | Full/Reduced bore Side Entry & Top Entry | Soft Seat & Metal seat Bolted & Welded | Flanged & Buttweld Design- Trunnion-mounted Ball Valve design complies to API 6D and can be offered with API 6D monogram

- Wide range of product portfolio in Side-entry and Top-entry designs

- Valves successfully tested to Shell Design Evaluation Test, Procedure 77/300 for temperature -29 to 150 degree C (O rings) and -50 to 150 degree C (Lip seals)

- Vaves for gas services can be supplied with High pressure gas test (Sniffing & Immersion Method)

- Coil springs used for consistent seat loading and lower operating torque

- Double block and bleed (DBB) feature - Valves are designed and tested for automatic cavity relief

- Lip seals are provided for low temperature services & Cryogenic services

- 2/3 stage Stem and 2 stage Body Joint sealing system; Primary O ring and Secondary graphite (in 3 stage stem, thrust washer is primary)

- Where tight shut off is required, Double piston effect (DPE) seats provided for redundancy in sealing

-

Features Floating Ball Valves Size 1/2" to 8" | ASME Class Class 150 to 2500 ISO 17292 | API 6D | API 608 1 Piece / 2 Piece / 3 Piece Construction Full / Reduced bore Soft Seat & Metal seat | Flanged-Screwed-Socket weld

Features Floating Ball Valves Size 1/2" to 8" | ASME Class Class 150 to 2500 ISO 17292 | API 6D | API 608 1 Piece / 2 Piece / 3 Piece Construction Full / Reduced bore Soft Seat & Metal seat | Flanged-Screwed-Socket weld- Mirror-finished solid stainless ball

- Fine-grained PTFE seats with Cavity Pressure Relief mechanism

- Blowout-proof stem & Antistatic feature

- High integrity stem sealing – Belleville springs compensate for wear and thermal expansions

- Actuator-mounting flange conforms to ISO 5211

-

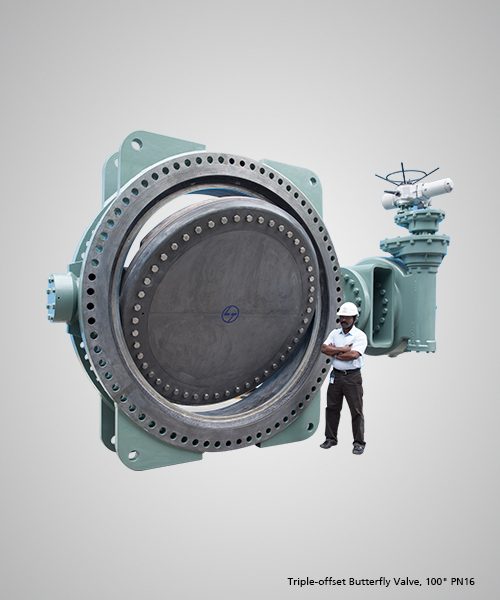

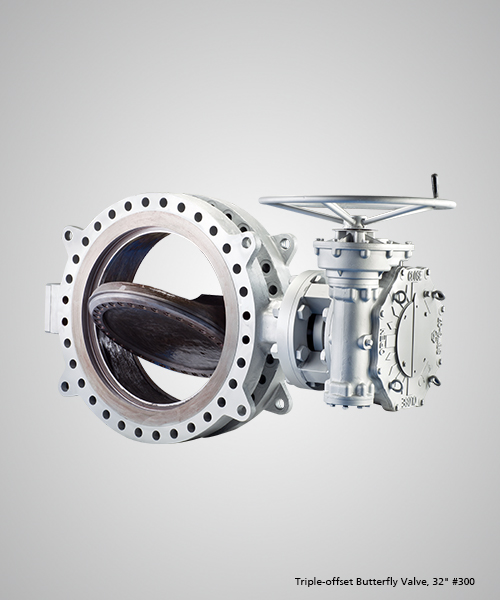

Special Features & Benefits Design complies to API 609 Valves offered with API 609 monogram Wide portfolio of Short-pattern and Long-pattern valves Design Validation Test - 12” Class 150 valve successfully completed 10,000 cycles Fugitive emissions - Complies to ISO 15848-1 Endurance Class CO2 and Tightness class AH Fire safe by design and complies to API 607/ ISO 10497 (preferred and non-preferred direction) API RP 591 test conducted on 12” Class 150 TOBV at Element Lab, USA CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design examination certificate (certified by DNV) available Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL3 Safety Integrity Level to IEC 61508 Triple-offset Geometry minimises seat-seal contact – lower operating torque and cost of ownership Compact and light weight as compared to gate valves of the same size Hard faced in-situ body seat and flexible laminar seal ensure bubble tight sealing Single piece Anti blow out shaft Disc contour ensures mimimum turbulence and pressure drop Retainer bolting complies to ASME Section VIII Div 1 Appendix 2

Special Features & Benefits Design complies to API 609 Valves offered with API 609 monogram Wide portfolio of Short-pattern and Long-pattern valves Design Validation Test - 12” Class 150 valve successfully completed 10,000 cycles Fugitive emissions - Complies to ISO 15848-1 Endurance Class CO2 and Tightness class AH Fire safe by design and complies to API 607/ ISO 10497 (preferred and non-preferred direction) API RP 591 test conducted on 12” Class 150 TOBV at Element Lab, USA CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design examination certificate (certified by DNV) available Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL3 Safety Integrity Level to IEC 61508 Triple-offset Geometry minimises seat-seal contact – lower operating torque and cost of ownership Compact and light weight as compared to gate valves of the same size Hard faced in-situ body seat and flexible laminar seal ensure bubble tight sealing Single piece Anti blow out shaft Disc contour ensures mimimum turbulence and pressure drop Retainer bolting complies to ASME Section VIII Div 1 Appendix 2