-

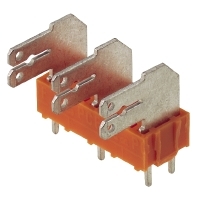

SL-SMT 5.08HC/270 High-temperature-resistant, straight, open pin header. Packed in box or tape. On tape and with 1.5 mm solder pin, optimised for automatic assembly. 3.2 mm solder pin suitable for reflow and wave soldering. The pin headers provide space for labelling and can be coded. HC = High Current.

SL-SMT 5.08HC/270 High-temperature-resistant, straight, open pin header. Packed in box or tape. On tape and with 1.5 mm solder pin, optimised for automatic assembly. 3.2 mm solder pin suitable for reflow and wave soldering. The pin headers provide space for labelling and can be coded. HC = High Current. -

The SC pin header has a perpendicular (standing) plugging direction in relation to the PCB. It is available in closed (G) and screw flange (F) versions. Weidmüller's 3.81-mm-pitch (0.15 inch) plug-in connectors are compatible with the layouts of standard connectors and offer space for labelling and coding.

The SC pin header has a perpendicular (standing) plugging direction in relation to the PCB. It is available in closed (G) and screw flange (F) versions. Weidmüller's 3.81-mm-pitch (0.15 inch) plug-in connectors are compatible with the layouts of standard connectors and offer space for labelling and coding. -

Two-row female plug with PUSH IN spring connection · the wire-entry area and handling area are clearly separated · Integrated push-buttons for opening the terminal point · High component density because of low heights · Optional: locking and releasing require no tools when using Weidmüller's · release latch (LR) or release lever (LH)

Two-row female plug with PUSH IN spring connection · the wire-entry area and handling area are clearly separated · Integrated push-buttons for opening the terminal point · High component density because of low heights · Optional: locking and releasing require no tools when using Weidmüller's · release latch (LR) or release lever (LH) -

'PUSH IN - Weidmüller's innovative connection system simplifies the wire connection process. The benefits for users and applications: High component density because of small pitch. Simply insert the prepared wire - and you're done Simplified processing, thanks to integrated push buttons for opening the terminal point Intuitive handling – since the conductor entry and handling areas are clearly separated

'PUSH IN - Weidmüller's innovative connection system simplifies the wire connection process. The benefits for users and applications: High component density because of small pitch. Simply insert the prepared wire - and you're done Simplified processing, thanks to integrated push buttons for opening the terminal point Intuitive handling – since the conductor entry and handling areas are clearly separated -

The pluggable PCB connection is the established standard in process and manufacturing automation as well as the measurement and control industry.

The pluggable PCB connection is the established standard in process and manufacturing automation as well as the measurement and control industry.- The wide line with many product series, provides design flexibility, efficient processing and safe, intuitive handling: 36 connections at 3.50 mm pitch, highest level of power reserves in 3.81 mm pitch and the largest application area in 5.08 mm pitch

- Application-oriented connection systems, from clamping-yoke screw connections to PUSH-IN spring connections

- A wide range of reflow compatible products for automated SMT processes

- Multi-row and multi-layer designs up to 48-pole

-

Accessories Integrate, expand and customise: the perfect supplement to every application. Universal system accessories enable easy adaptation of the interfaces to fulfil specific requirements for the relevant application. The following options are available depending on the system: installing and fastening components Signalling and checking statuses Marking and labelling components Potential distribution and separation Only the right high-quality tools will ensure professional working standards. All in all: ease of operation, maximum functionality and safety for the application and the user. Industrial

Accessories Integrate, expand and customise: the perfect supplement to every application. Universal system accessories enable easy adaptation of the interfaces to fulfil specific requirements for the relevant application. The following options are available depending on the system: installing and fastening components Signalling and checking statuses Marking and labelling components Potential distribution and separation Only the right high-quality tools will ensure professional working standards. All in all: ease of operation, maximum functionality and safety for the application and the user. Industrial- Electronic

- Other

-

Flat-blade connection The traditional single-wire connection – versatile, simple and cost-effective: PCB terminals with cable-lug connection – the PCF system. High current-carrying capacity up to 24 A (IEC) or 15 A (UL) 3 pitches (5.0 / 7.5 / 10.0 mm) for voltages up to 1000 V (IEC) or 300 V (UL) 3 outlet directions in relation to the PCB (90 / 135 / 180°) For mounting side by side or fixed number of poles, between 2 and 19 connector lugs Can be used with 2.8 and 6.3 mm flat blade receptacles Suitable for insulated and uninsulated receptacles For applications requiring the quick and easy connection of pre-assembled conductors to PCBs. A simple solution for simple connections: inexpensive Faston connection system for PCBs. Industrials

Flat-blade connection The traditional single-wire connection – versatile, simple and cost-effective: PCB terminals with cable-lug connection – the PCF system. High current-carrying capacity up to 24 A (IEC) or 15 A (UL) 3 pitches (5.0 / 7.5 / 10.0 mm) for voltages up to 1000 V (IEC) or 300 V (UL) 3 outlet directions in relation to the PCB (90 / 135 / 180°) For mounting side by side or fixed number of poles, between 2 and 19 connector lugs Can be used with 2.8 and 6.3 mm flat blade receptacles Suitable for insulated and uninsulated receptacles For applications requiring the quick and easy connection of pre-assembled conductors to PCBs. A simple solution for simple connections: inexpensive Faston connection system for PCBs. Industrials- Electronic

- Other

-

Tension clamp spring connection Weidmüller tension-clamp connections - simple, quick and proven reliable: The universal screw-free connection with steel spring – ideal for PCB installation terminals. Wiring with demanding requirements for cost-effective connections with contact stability. Industrial

Tension clamp spring connection Weidmüller tension-clamp connections - simple, quick and proven reliable: The universal screw-free connection with steel spring – ideal for PCB installation terminals. Wiring with demanding requirements for cost-effective connections with contact stability. Industrial- Electronic

- Other

-

PUSH IN spring connection The innovative quick connector - simple, safe and economical: PCB terminals with spring connection and direct PUSH IN technology. A milestone in connection technology. Amazingly simple and simply amazing in practice: Connect and easily detach solid wires or wires with wire-end ferrules without using tools Processed automatically in the reflow or vapour phase Potentials and clamping points marked clearly by coloured push buttons World-class design-in and processing phases, and suitable for a vast range of applications. Industrial

PUSH IN spring connection The innovative quick connector - simple, safe and economical: PCB terminals with spring connection and direct PUSH IN technology. A milestone in connection technology. Amazingly simple and simply amazing in practice: Connect and easily detach solid wires or wires with wire-end ferrules without using tools Processed automatically in the reflow or vapour phase Potentials and clamping points marked clearly by coloured push buttons World-class design-in and processing phases, and suitable for a vast range of applications. Industrial- Electronic

- Other

-

TOP-screw connection Screw connection with optimised design - easy to use and minimum space requirements br /> TOP GS PCB terminal system with TOP screw connection. Operated from one side only. Optional: ATEX approval. Operated from one side and extremely versatile: · High current-carrying capacity up to 32 A (IEC) or 30 A (UL) · 3 pitches (5.08 / 6.35 / 7.62 mm) for voltages up to 1000V (IEC) or 300 V (UL) · Enormous connection capacity, cross-sections up to 6 mm² · 2 outlet directions in relation to the PCB (90 / 180°) · For mounting side by side or fixed number of poles, up to 24 connections · Explosion-protected variations for ATEX zones · Attachment profile for Dekafix markers Sophisticated design and user-friendly wiring - conductor connected and the clamping point accessed from the same direction (TOP) TOP GS: the special terminal for special applications. Industrial

TOP-screw connection Screw connection with optimised design - easy to use and minimum space requirements br /> TOP GS PCB terminal system with TOP screw connection. Operated from one side only. Optional: ATEX approval. Operated from one side and extremely versatile: · High current-carrying capacity up to 32 A (IEC) or 30 A (UL) · 3 pitches (5.08 / 6.35 / 7.62 mm) for voltages up to 1000V (IEC) or 300 V (UL) · Enormous connection capacity, cross-sections up to 6 mm² · 2 outlet directions in relation to the PCB (90 / 180°) · For mounting side by side or fixed number of poles, up to 24 connections · Explosion-protected variations for ATEX zones · Attachment profile for Dekafix markers Sophisticated design and user-friendly wiring - conductor connected and the clamping point accessed from the same direction (TOP) TOP GS: the special terminal for special applications. Industrial- Electronic

- Other

-

Clamping yoke screw connection The undisputed no. 1 in screw connection technology - billions of tried and tested, internationally recognised, completely maintenance-free components: Circuit board terminals with clamping yoke screw connection - the market standard by Weidmüller. Continually growing: the most extensive range of terminals on the market: 6 connection cross-sections from 0.08 to 25mm² Maximum current-carrying capacity of 101A at ambient temperatures of 40° (IEC) 3 conductor outlet directions (90 / 135 / 180°) Single level and multi level enclosure Reliability personified: 100% versatile - clamping range < 0,2mm ...>15 mm² 100% flexible - for solid or flexible conductors, also without AEH 100% maintenance-free due to self-locking screw retention device 100% reliable contact - gas-tight and vibration-proof Specific material selection: steel for strength and copper for conductivity. Widely recognised and guaranteed reliability - the indispensable connection system compatible with every device series. Industrial

Clamping yoke screw connection The undisputed no. 1 in screw connection technology - billions of tried and tested, internationally recognised, completely maintenance-free components: Circuit board terminals with clamping yoke screw connection - the market standard by Weidmüller. Continually growing: the most extensive range of terminals on the market: 6 connection cross-sections from 0.08 to 25mm² Maximum current-carrying capacity of 101A at ambient temperatures of 40° (IEC) 3 conductor outlet directions (90 / 135 / 180°) Single level and multi level enclosure Reliability personified: 100% versatile - clamping range < 0,2mm ...>15 mm² 100% flexible - for solid or flexible conductors, also without AEH 100% maintenance-free due to self-locking screw retention device 100% reliable contact - gas-tight and vibration-proof Specific material selection: steel for strength and copper for conductivity. Widely recognised and guaranteed reliability - the indispensable connection system compatible with every device series. Industrial- Electronic

- Other

-

USB plug-in connectors Universal serial bus 2.0 and 3.0 (SuperSpeed); Type A connectors meet the requirements for high resistance and provide reliable connectivity. • Up to 5000 plugging cycles • THT, THR or SMD soldering processes • Available in design types 180° (vertical/upright) or 90° (horizontal/flat-lying) • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Reinforced gold layer for improved corrosion protection

USB plug-in connectors Universal serial bus 2.0 and 3.0 (SuperSpeed); Type A connectors meet the requirements for high resistance and provide reliable connectivity. • Up to 5000 plugging cycles • THT, THR or SMD soldering processes • Available in design types 180° (vertical/upright) or 90° (horizontal/flat-lying) • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Reinforced gold layer for improved corrosion protection -

RJ45 sockets – transformer RJ45 transmitter sockets (magnetics) for gigabit applications (1000 base-T) with integrated compensation actively counteracts inductive and capacitive couplings and saves space on the PCB. • THT or THR soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s Industrial

RJ45 sockets – transformer RJ45 transmitter sockets (magnetics) for gigabit applications (1000 base-T) with integrated compensation actively counteracts inductive and capacitive couplings and saves space on the PCB. • THT or THR soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s Industrial- Electronic

- Other

-

RJ45 sockets Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s Industrial

RJ45 sockets Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s Industrial- Electronic

- Other

-

Description Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s

Description Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s -

Description Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s

Description Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s -

Description Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s

Description Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s -

Description TS 35X7.5/LL 2M/ST/ZN

Description TS 35X7.5/LL 2M/ST/ZN- Mounting rail, TS 35, TS 35 x 7.5, with slot, Steel, galvanized, chromium-plated

- Mounting rail, TS 35, TS 35 x 15, with slot, Steel, galvanized, chromium-platedTS

- Mounting rail, TS 35, TS 35 x 7.5, without slot, Stainless steel, untreated

-

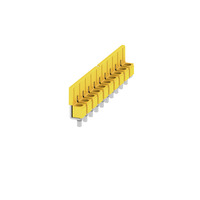

Description WQV 2.5/10 GE

Description WQV 2.5/10 GE- W-Series, Cross-connector, For the terminals WDU 2.5,WTR 2.5,WDK 2.5 No. of poles: 10

- W-Series, Cross-connector, For the terminals WDU 4, WTR 4, No. of poles: 10

- W-Series, Cross-connector, For the terminals WDU 6, No. of poles: 10

- W-Series, Cross-connector, For the terminals WDU 10, WDK 10, No. of poles: 10

- W-Series, Cross-connector, For the terminals WDU 16 No. of poles: 10

- W-Series, Cross-connector, For the terminals WDU 35, No. of poles: 10

- W-Series, Cross-connector, For the terminals WDU50N, No. of poles: 2

- W-Series, Cross-connector, For the terminals WDU70/95, No. of poles: 2

- W-Series, Cross-connector, For the terminals WDU95N/120N, No. of poles: 2

- W-Series, Cross-connector, For the terminals WDU 120/150, No. of poles: 2

-

Description WAP 2.5-10

Description WAP 2.5-10- W-Series, End plate for WDU 2.5 TO WDU 10, WTR 2.5,WSI 2.5/SI,WSI 6

- W-Series, End plate blue for WDU 2.5 BL TO WDU 10 BL, WTR 2.BL,WSI 6 BL

- W-Series, End plate for WDU 16 TO WDU35, WPE 16 TO WPE 35/ partition plate for WDU 2.5 TO WDU 10, WTR 2.5,WSI 6

- W-Series, End plate blue for WDU 16 TO WDU35, WPE 16 TO WPE 35/ partition plate for WDU 2.5 TO WDU 10, WTR 2.5,WSI 6

- W-Series, End plate for WDK 2.5, WDK 2.5 PE

- W-Series, End plate for WDK 2.5 BL

- W-Series, Seperation plate

- W-Series, End plate for WDK 10

- W-Series, End plate for WDK 10 BL

-

WTR 2.5

WTR 2.5- Test-disconnect terminal, Screw connection, 2.5 mm², 500 V, 24 A, Pivoting, Dark Beige

- Test-disconnect terminal, Screw connection, 2.5 mm², 500 V, 24 A, Pivoting, Blue

- Test-disconnect terminal, Screw connection, 4 mm², 400 V, 32 A, Pivoting, Dark Beige

- Test-disconnect terminal, Screw connection, 4 mm², 400 V, 32 A, Pivoting, Blue

-

Description WTR 2.5/SI

Description WTR 2.5/SI- W-Series, Fuse terminal, Rated cross-section: 2.5 mm², Screw connection

- W-Series, Fuse terminal, Rated cross-section: 4 mm², Screw connection

- W-Series, Fuse terminal with LED 10-36 VDC/AC, Rated cross-section: 4 mm², Screw connection

- W-Series, Fuse terminal with LED 140-250 VDC/AC, Rated cross-section: 4 mm², Screw connection

- W-Series, Fuse terminal, Rated cross-section: 6 mm², Screw connection, FUSE 5X20 mm

- W-Series, Fuse terminal with LED 10-36 VDC/AC, Rated cross-section: 6 mm², Screw connection, FUSE 5X20 mm

- W-Series, Fuse terminal with LED 250 AC, Rated cross-section: 6 mm², Screw connection, FUSE 5X20 mm

-

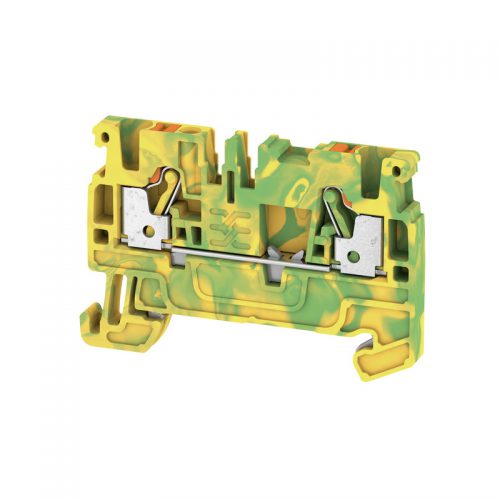

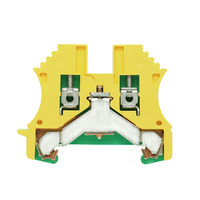

Description WPE 2.5

Description WPE 2.5- PE terminal, Screw connection, 2.5 mm², 300 A (2.5 mm²), green / yellow

- PE terminal, Screw connection, 4 mm², 480 A (4 mm²), green / yellow

- PE terminal, Screw connection, 6 mm², 720 A (6 mm²), green / yellow

- PE terminal, Screw connection, 10 mm², 1200 A (10 mm²), green / yellow

- PE terminal, Screw connection, 16 mm², 1920 A (16 mm²), green / yellow

- PE terminal, Screw connection, 35 mm², 4200 A (35 mm²), green / yellow

- PE terminal, Screw connection, 50 mm², 6000 A (50 mm²), green / yellow

- PE terminal, Screw connection, 95 mm², 11400 A (95 mm²), green / yellow

- PE terminal, Screw connection, 95 mm², 11400 A (95 mm²), green / yellow

- PE terminal, Screw connection, 120 mm², 14400 A (120 mm²), green / yellow

-

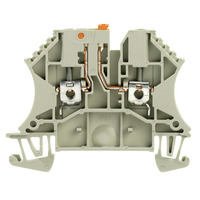

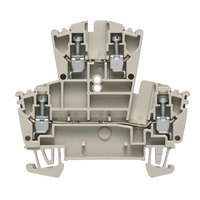

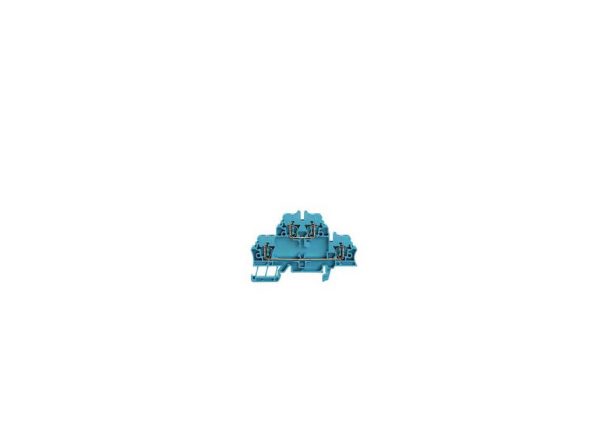

Description WDK 2.5

Description WDK 2.5- Feed-through terminal, Double-tier terminal, Screw connection, 2.5 mm², 400 V, 24 A, Dark Beige

- Feed-through terminal, Double-tier terminal, Screw connection, 2.5 mm², 400 V, 24 A, Blue

- Feed-through terminal, Double-tier terminal, Screw connection, 10 mm², 800 V, 57 A, Dark Beige

- Feed-through terminal, Double-tier terminal, Screw connection, 10 mm², 800 V, 57 A, Blue

-

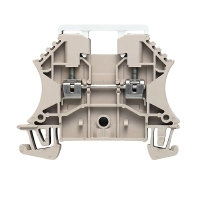

Description WDU 2.5

Description WDU 2.5- Feed-through terminal, Screw connection, 2.5 mm², 800 V, 24 A, Dark Beige

- Feed-through terminal, Screw connection, 2.5 mm², 800 V, 24 A, Blue

- W-Series, Feed-through terminal, Thermocouple TYPE K, Rated cross-section: 2.5 mm², Screw connection

- Feed-through terminal, Screw connection, 4 mm², 800 V, 32 A, Dark Beige

- Feed-through terminal, Screw connection, 4 mm², 800 V, 32 A, Blue

- Feed-through terminal, Screw connection, 6 mm², 800 V, 41 A, Dark Beige

- Feed-through terminal, Screw connection, 6 mm², 800 V, 41 A, Blue

- Feed-through terminal, Screw connection, 10 mm², 1000 V, 57 A, Dark Beige

- Feed-through terminal, Screw connection, 10 mm², 1000 V, 57 A, Blue

- Feed-through terminal, Screw connection, 16 mm², 1000 V, 76 A, Dark Beige

- Feed-through terminal, Screw connection, 16 mm², 1000 V, 76 A, Blue

- Feed-through terminal, Screw connection, 35 mm², 1000 V, 125 A, Dark Beige

- Feed-through terminal, Screw connection, 35 mm², 1000 V, 125 A, Blue

- Feed-through terminal, Screw connection, 50 mm², 1000 V, 150 A, Dark Beige

- Feed-through terminal, Screw connection, 50 mm², 1000 V, 150 A, Blue

- Feed-through terminal, Screw connection, 70 mm², 1000 V, 192 A, Dark Beige

- Feed-through terminal, Screw connection, 70 mm², 1000 V, 192 A, Blue

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Dark Beige

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Blue

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Dark Beige

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Blue

- Feed-through terminal, Screw connection, 240 mm², 1000 V, 415 A, Dark Beige

- Feed-through terminal, Screw connection, 240 mm², 1000 V, 415 A, Blue

-

Description TS 35X7.5/LL 2M/ST/ZN

Description TS 35X7.5/LL 2M/ST/ZN- Mounting rail, TS 35, TS 35 x 7.5, with slot, Steel, galvanized, chromium-plated

- Mounting rail, TS 35, TS 35 x 15, with slot, Steel, galvanized, chromium-plated

- Mounting rail, TS 35, TS 35 x 7.5, without slot, Stainless steel, untreated

-

Description ZQV 2.5/10 GE

Description ZQV 2.5/10 GE- Z-series, Accessories,cross connection for ZDU 2.5, ZDK 2.5, ZTR 2.5 (10 poles)

- Z-series, Accessories,cross connection for ZDU 4(10 poles)

- Z-series, Accessories,cross connection for ZDU 6(24 poles)

- Z-series, Accessories,cross connection for ZDU 10(24poles)

- Z-series, Accessories,cross connection for ZDU 10( 2 poles)

- Z-series, Accessories,cross connection for ZDU 35 ( 2 poles)

-

Description ZAP/TW1

Description ZAP/TW1- Z-series, Accessories, End plate, Seperation plate for ZDU 2.5,ZPE 2.5,ZTR2.5

- Z-series, Accessories, End plate, Seperation plate for ZDU 2.5 BL,ZTR 2.5 BL

- Z-series, Accessories, End plate, Seperation plate for ZSI 2.5, ZSI 2.5/LD 28 AC, ZSI 2.5/LD 120 AC, ZSI 2.5/LD250 AC,ZDU 2.5/2X2AN/D+,ZDU 2.5/2X2AN/D-

- Z-series, Accessories, End plate, Seperation plate for ZDU 4

- Z-series, Accessories, End plate, Seperation plate for ZDU 4 BL

- Z-series, Accessories, End plate, Seperation plate for ZDU 6, ZPE 6

- Z-series, Accessories, End plate, Seperation plate for ZDU 6 BL

- Z-series, Accessories, End plate, Seperation plate for ZDU 10, ZPE 10

- Z-series, Accessories, End plate, Seperation plate for ZDU 10 BL

- series, Accessories, End plate for ZDU 16, ZPE 16

- Z-series, Accessories, End plate for ZDU 16 BL

- Z-series, Accessories, End plate, Seperation plate for ZDK 2.5

- Z-series, Accessories, End plate, Seperation plate for ZDK 2.5 BL

-

DescriptionZSI ZSI 2.5

DescriptionZSI ZSI 2.5- Z-series, Fuse terminal, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

- Z-series, Fuse terminal with LED 28VAC, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

- Z-series, Fuse terminal with LED 120VAC, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

- Z-series, Fuse terminal with LED 250VAC, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

-

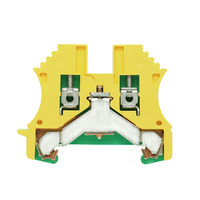

Modular PE terminal blocks 1 tier ZPE 2.5 - PE terminal, Tension clamp connection, 2.5 mm², 300 A (2.5 mm²), green / yellow ZPE 4 - PE terminal, Tension clamp connection, 4 mm², 480 A (4 mm²), green / yellow ZPE 6 - PE terminal, Tension clamp connection, 6 mm², 720 A (6 mm²), green / yellow ZPE 10 - PE terminal, Tension clamp connection, 10 mm², 1200 A (10 mm²), green / yellow ZPE 16 - PE terminal, Tension clamp connection, 16 mm², 1920 A (16 mm²), green / yellow ZPE 35 - PE terminal, Tension clamp connection, 35 mm², 4200 A (35 mm²), green / yellow Modular PE terminal blocks 2 tier ZDK 2.5 - Double-tier terminal, PE terminal, Tension clamp connection, 2.5 mm², 300 A (2.5 mm²), green / yellow

Modular PE terminal blocks 1 tier ZPE 2.5 - PE terminal, Tension clamp connection, 2.5 mm², 300 A (2.5 mm²), green / yellow ZPE 4 - PE terminal, Tension clamp connection, 4 mm², 480 A (4 mm²), green / yellow ZPE 6 - PE terminal, Tension clamp connection, 6 mm², 720 A (6 mm²), green / yellow ZPE 10 - PE terminal, Tension clamp connection, 10 mm², 1200 A (10 mm²), green / yellow ZPE 16 - PE terminal, Tension clamp connection, 16 mm², 1920 A (16 mm²), green / yellow ZPE 35 - PE terminal, Tension clamp connection, 35 mm², 4200 A (35 mm²), green / yellow Modular PE terminal blocks 2 tier ZDK 2.5 - Double-tier terminal, PE terminal, Tension clamp connection, 2.5 mm², 300 A (2.5 mm²), green / yellow -

Feed-through terminal blocks 1-tier ZDU 2.5 - Feed-through terminal, Tension clamp connection, 2.5 mm², 24 A, Dark Beige ZDU 2.5 BL - Feed-through terminal, Tension clamp connection, 2.5 mm², 800 V, 24 A, Blue ZDU 4 - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Dark Beige ZDU 4 BL - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Blue ZDU 6 - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A, Dark Beige ZDU 6 BL - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A,Blue ZDU 10 - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Dark Beige ZDU 10 BL - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Blue ZDU 16 - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Dark Beige ZDU 16 BL - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Blue Feed-through terminal blocks 2-Tier ZDK 2.5 - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Beige ZDK 2.5 BL - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Blue

Feed-through terminal blocks 1-tier ZDU 2.5 - Feed-through terminal, Tension clamp connection, 2.5 mm², 24 A, Dark Beige ZDU 2.5 BL - Feed-through terminal, Tension clamp connection, 2.5 mm², 800 V, 24 A, Blue ZDU 4 - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Dark Beige ZDU 4 BL - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Blue ZDU 6 - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A, Dark Beige ZDU 6 BL - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A,Blue ZDU 10 - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Dark Beige ZDU 10 BL - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Blue ZDU 16 - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Dark Beige ZDU 16 BL - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Blue Feed-through terminal blocks 2-Tier ZDK 2.5 - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Beige ZDK 2.5 BL - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Blue -

End Plate AEP 2C 2.5 - End Plate for A2C 2.5,A2C 2.5 PE AEP 2C 2.5 BL - End Plate for A2C 2.5 BL AEP 2C 4 - End Plate for A2C 4,A2C 4 PE AEP 2C 4 BL - End Plate for A2C 4 BL AEP 2C 6 - End Plate for A2C 6, A2C 6 PE AEP 2C 10/16 - End Plate for A2C 10, A2C 16, A2C 10 PE, A2C 16 PE AEP 2C 10/16 BL - End Plate for A2C 10 BL, A2C 16 BL AEP 2T 2.5 - End Plate for A2T 2.5 AEP 3T 2.5 - End Plate for A3T 2.5 AEP 4C 2.5 - End Plate for AFS 2.5 CF 2C BK, AFS 2.5 CF 2C 12V BK, AFS 2.5 CF 2C 24V BK AEP 3C 4 - End Plate for AFS 4 2C BK, AFS 4 2C 10-36V BK, AFS 4 2C 30-70V BK, AFS 4 2C 100-250V BK End Stopper AEB 35 SC/1 - A-series, End bracket Cross Connection ZQV 2.5N/10 - Cross Connection for 2.5 mm2, 10 poles ZQV 6N/4 - Cross Connection for 6 mm2, 4 poles ZQV 10N/2 - Cross Connection for 10 mm2, 2 poles ZQV 16N/2 - Cross Connection for 16 mm2, 2 poles

End Plate AEP 2C 2.5 - End Plate for A2C 2.5,A2C 2.5 PE AEP 2C 2.5 BL - End Plate for A2C 2.5 BL AEP 2C 4 - End Plate for A2C 4,A2C 4 PE AEP 2C 4 BL - End Plate for A2C 4 BL AEP 2C 6 - End Plate for A2C 6, A2C 6 PE AEP 2C 10/16 - End Plate for A2C 10, A2C 16, A2C 10 PE, A2C 16 PE AEP 2C 10/16 BL - End Plate for A2C 10 BL, A2C 16 BL AEP 2T 2.5 - End Plate for A2T 2.5 AEP 3T 2.5 - End Plate for A3T 2.5 AEP 4C 2.5 - End Plate for AFS 2.5 CF 2C BK, AFS 2.5 CF 2C 12V BK, AFS 2.5 CF 2C 24V BK AEP 3C 4 - End Plate for AFS 4 2C BK, AFS 4 2C 10-36V BK, AFS 4 2C 30-70V BK, AFS 4 2C 100-250V BK End Stopper AEB 35 SC/1 - A-series, End bracket Cross Connection ZQV 2.5N/10 - Cross Connection for 2.5 mm2, 10 poles ZQV 6N/4 - Cross Connection for 6 mm2, 4 poles ZQV 10N/2 - Cross Connection for 10 mm2, 2 poles ZQV 16N/2 - Cross Connection for 16 mm2, 2 poles -

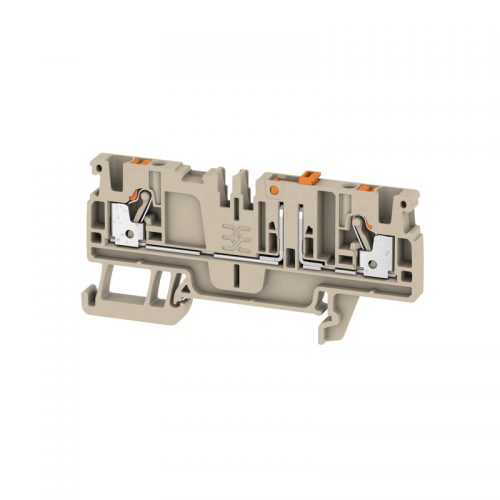

Description ADT 2.5 2C - Test-disconnect terminal, PUSH IN, 2.5 mm², 500 V, 20 A, Dark Beige ADT 2.5 2C BL - Test-disconnect terminal, PUSH IN, 2.5 mm², 500 V, 20 A,Blue ADT 4 2C - Test-disconnect terminal, PUSH IN, 4 mm², 500 V, 20 A, Dark Beige ADT 4 2C BL - Test-disconnect terminal, PUSH IN, 4 mm², 500 V, 20 A,Blue

Description ADT 2.5 2C - Test-disconnect terminal, PUSH IN, 2.5 mm², 500 V, 20 A, Dark Beige ADT 2.5 2C BL - Test-disconnect terminal, PUSH IN, 2.5 mm², 500 V, 20 A,Blue ADT 4 2C - Test-disconnect terminal, PUSH IN, 4 mm², 500 V, 20 A, Dark Beige ADT 4 2C BL - Test-disconnect terminal, PUSH IN, 4 mm², 500 V, 20 A,Blue -

AFS 2.5 CF 2C BK -Fuse terminal, PUSH IN, 2.5 mm², 250 V, 10 A, Black AFS 2.5 CF 2C 12V BK - Fuse terminal, PUSH IN, 2.5 mm², 12 V, 10 A, Black AFS 2.5 CF 2C 24V BK - Fuse terminal, PUSH IN, 2.5 mm², 24 V, 10 A, Black AFS 4 2C BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black AFS 4 2C 10-36V BK - Fuse terminal, PUSH IN, 4 mm², 36 V, 6.3 A, Black AFS 4 2C 30-70V BK - Fuse terminal, PUSH IN, 4 mm², 70 V, 6.3 A, Black AFS 4 2C 100-250V BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black

AFS 2.5 CF 2C BK -Fuse terminal, PUSH IN, 2.5 mm², 250 V, 10 A, Black AFS 2.5 CF 2C 12V BK - Fuse terminal, PUSH IN, 2.5 mm², 12 V, 10 A, Black AFS 2.5 CF 2C 24V BK - Fuse terminal, PUSH IN, 2.5 mm², 24 V, 10 A, Black AFS 4 2C BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black AFS 4 2C 10-36V BK - Fuse terminal, PUSH IN, 4 mm², 36 V, 6.3 A, Black AFS 4 2C 30-70V BK - Fuse terminal, PUSH IN, 4 mm², 70 V, 6.3 A, Black AFS 4 2C 100-250V BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black -

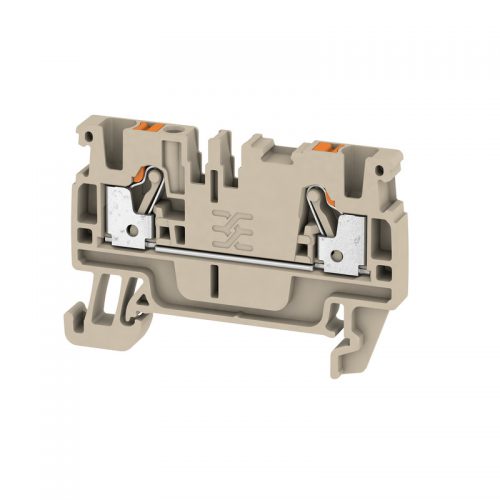

Description Spring connection with PUSH IN Technology. The innovative PUSH IN technology reduces the amount of time you spend on wiring to a minimum. Direct insertion guarantees high conductor pull-out forces and simple handling for all conductor types. Industrial

Description Spring connection with PUSH IN Technology. The innovative PUSH IN technology reduces the amount of time you spend on wiring to a minimum. Direct insertion guarantees high conductor pull-out forces and simple handling for all conductor types. Industrial- Oil & Gas

- Chemical & Petrochemical

- Paper

- Steel

- Pulp & Paper

- Electronic

- Renewable Energy

- Transportation

-

Application Designed to house systems incorporating large components or complex mounting configurations. Three-point latching and sealing provide industry-leading protection from dust, dirt, oil and water. These enclosures are used in machine tool applications for housing motor starters, drives, contactors and PLCs, as well as a wide variety of other electrical and electronic equipment. The addition of 19-in. rack-mounting accessories makes these enclosures ideal for providing rugged protection for sensitive rack-mounted components in harsh industrial environments. These enclosures are used extensively in automotive, pulp and paper, wood products, textile and similar industries. Size 60.06 x 48.06 x 18.06 - 90.06 x 72.06 x 36.06

Application Designed to house systems incorporating large components or complex mounting configurations. Three-point latching and sealing provide industry-leading protection from dust, dirt, oil and water. These enclosures are used in machine tool applications for housing motor starters, drives, contactors and PLCs, as well as a wide variety of other electrical and electronic equipment. The addition of 19-in. rack-mounting accessories makes these enclosures ideal for providing rugged protection for sensitive rack-mounted components in harsh industrial environments. These enclosures are used extensively in automotive, pulp and paper, wood products, textile and similar industries. Size 60.06 x 48.06 x 18.06 - 90.06 x 72.06 x 36.06 -

Application Designed to house systems incorporating large components or complex mounting configurations. Three-point latching and sealing provide industry-leading protection from dust, dirt, oil and water. These enclosures are used in machine tool applications for housing motor starters, drives, contactors and PLCs, as well as a wide variety of other electrical and electronic equipment. The addition of 19-in. rack-mounting accessories makes these enclosures ideal for providing rugged protection for sensitive rack-mounted components in harsh industrial environments. These enclosures are used extensively in automotive, pulp and paper, wood products, textile and similar industries. Four styles are available to provide maximum flexibility Size 60.06 x 24.06 x 18.06 - 90.06 x 36.06 x 36.06

Application Designed to house systems incorporating large components or complex mounting configurations. Three-point latching and sealing provide industry-leading protection from dust, dirt, oil and water. These enclosures are used in machine tool applications for housing motor starters, drives, contactors and PLCs, as well as a wide variety of other electrical and electronic equipment. The addition of 19-in. rack-mounting accessories makes these enclosures ideal for providing rugged protection for sensitive rack-mounted components in harsh industrial environments. These enclosures are used extensively in automotive, pulp and paper, wood products, textile and similar industries. Four styles are available to provide maximum flexibility Size 60.06 x 24.06 x 18.06 - 90.06 x 36.06 x 36.06