-

Description Spring connection with PUSH IN Technology. The innovative PUSH IN technology reduces the amount of time you spend on wiring to a minimum. Direct insertion guarantees high conductor pull-out forces and simple handling for all conductor types. Industrial

Description Spring connection with PUSH IN Technology. The innovative PUSH IN technology reduces the amount of time you spend on wiring to a minimum. Direct insertion guarantees high conductor pull-out forces and simple handling for all conductor types. Industrial- Oil & Gas

- Chemical & Petrochemical

- Paper

- Steel

- Pulp & Paper

- Electronic

- Renewable Energy

- Transportation

-

AFS 2.5 CF 2C BK -Fuse terminal, PUSH IN, 2.5 mm², 250 V, 10 A, Black AFS 2.5 CF 2C 12V BK - Fuse terminal, PUSH IN, 2.5 mm², 12 V, 10 A, Black AFS 2.5 CF 2C 24V BK - Fuse terminal, PUSH IN, 2.5 mm², 24 V, 10 A, Black AFS 4 2C BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black AFS 4 2C 10-36V BK - Fuse terminal, PUSH IN, 4 mm², 36 V, 6.3 A, Black AFS 4 2C 30-70V BK - Fuse terminal, PUSH IN, 4 mm², 70 V, 6.3 A, Black AFS 4 2C 100-250V BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black

AFS 2.5 CF 2C BK -Fuse terminal, PUSH IN, 2.5 mm², 250 V, 10 A, Black AFS 2.5 CF 2C 12V BK - Fuse terminal, PUSH IN, 2.5 mm², 12 V, 10 A, Black AFS 2.5 CF 2C 24V BK - Fuse terminal, PUSH IN, 2.5 mm², 24 V, 10 A, Black AFS 4 2C BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black AFS 4 2C 10-36V BK - Fuse terminal, PUSH IN, 4 mm², 36 V, 6.3 A, Black AFS 4 2C 30-70V BK - Fuse terminal, PUSH IN, 4 mm², 70 V, 6.3 A, Black AFS 4 2C 100-250V BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black -

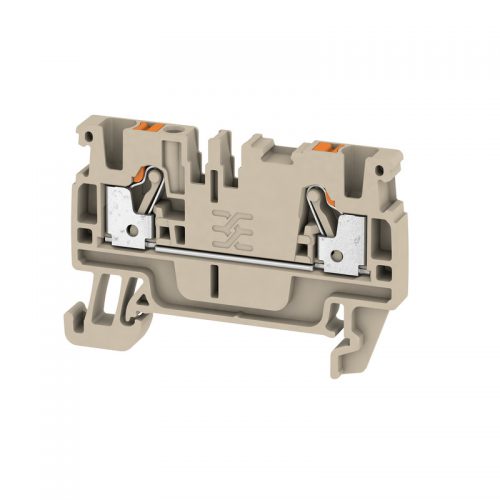

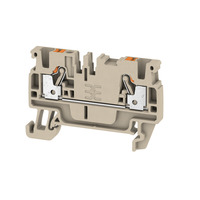

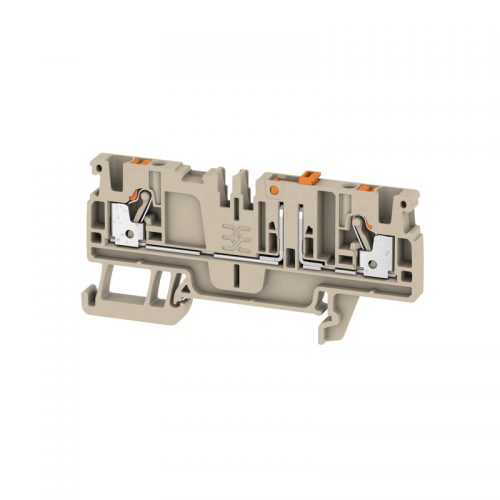

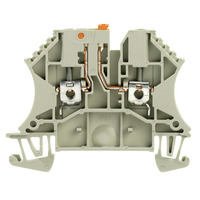

Description ADT 2.5 2C - Test-disconnect terminal, PUSH IN, 2.5 mm², 500 V, 20 A, Dark Beige ADT 2.5 2C BL - Test-disconnect terminal, PUSH IN, 2.5 mm², 500 V, 20 A,Blue ADT 4 2C - Test-disconnect terminal, PUSH IN, 4 mm², 500 V, 20 A, Dark Beige ADT 4 2C BL - Test-disconnect terminal, PUSH IN, 4 mm², 500 V, 20 A,Blue

Description ADT 2.5 2C - Test-disconnect terminal, PUSH IN, 2.5 mm², 500 V, 20 A, Dark Beige ADT 2.5 2C BL - Test-disconnect terminal, PUSH IN, 2.5 mm², 500 V, 20 A,Blue ADT 4 2C - Test-disconnect terminal, PUSH IN, 4 mm², 500 V, 20 A, Dark Beige ADT 4 2C BL - Test-disconnect terminal, PUSH IN, 4 mm², 500 V, 20 A,Blue -

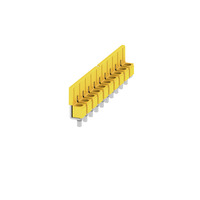

End Plate AEP 2C 2.5 - End Plate for A2C 2.5,A2C 2.5 PE AEP 2C 2.5 BL - End Plate for A2C 2.5 BL AEP 2C 4 - End Plate for A2C 4,A2C 4 PE AEP 2C 4 BL - End Plate for A2C 4 BL AEP 2C 6 - End Plate for A2C 6, A2C 6 PE AEP 2C 10/16 - End Plate for A2C 10, A2C 16, A2C 10 PE, A2C 16 PE AEP 2C 10/16 BL - End Plate for A2C 10 BL, A2C 16 BL AEP 2T 2.5 - End Plate for A2T 2.5 AEP 3T 2.5 - End Plate for A3T 2.5 AEP 4C 2.5 - End Plate for AFS 2.5 CF 2C BK, AFS 2.5 CF 2C 12V BK, AFS 2.5 CF 2C 24V BK AEP 3C 4 - End Plate for AFS 4 2C BK, AFS 4 2C 10-36V BK, AFS 4 2C 30-70V BK, AFS 4 2C 100-250V BK End Stopper AEB 35 SC/1 - A-series, End bracket Cross Connection ZQV 2.5N/10 - Cross Connection for 2.5 mm2, 10 poles ZQV 6N/4 - Cross Connection for 6 mm2, 4 poles ZQV 10N/2 - Cross Connection for 10 mm2, 2 poles ZQV 16N/2 - Cross Connection for 16 mm2, 2 poles

End Plate AEP 2C 2.5 - End Plate for A2C 2.5,A2C 2.5 PE AEP 2C 2.5 BL - End Plate for A2C 2.5 BL AEP 2C 4 - End Plate for A2C 4,A2C 4 PE AEP 2C 4 BL - End Plate for A2C 4 BL AEP 2C 6 - End Plate for A2C 6, A2C 6 PE AEP 2C 10/16 - End Plate for A2C 10, A2C 16, A2C 10 PE, A2C 16 PE AEP 2C 10/16 BL - End Plate for A2C 10 BL, A2C 16 BL AEP 2T 2.5 - End Plate for A2T 2.5 AEP 3T 2.5 - End Plate for A3T 2.5 AEP 4C 2.5 - End Plate for AFS 2.5 CF 2C BK, AFS 2.5 CF 2C 12V BK, AFS 2.5 CF 2C 24V BK AEP 3C 4 - End Plate for AFS 4 2C BK, AFS 4 2C 10-36V BK, AFS 4 2C 30-70V BK, AFS 4 2C 100-250V BK End Stopper AEB 35 SC/1 - A-series, End bracket Cross Connection ZQV 2.5N/10 - Cross Connection for 2.5 mm2, 10 poles ZQV 6N/4 - Cross Connection for 6 mm2, 4 poles ZQV 10N/2 - Cross Connection for 10 mm2, 2 poles ZQV 16N/2 - Cross Connection for 16 mm2, 2 poles -

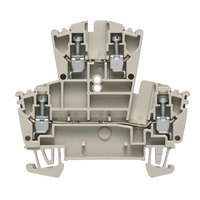

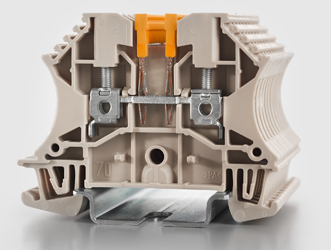

Feed-through terminal blocks 1-tier ZDU 2.5 - Feed-through terminal, Tension clamp connection, 2.5 mm², 24 A, Dark Beige ZDU 2.5 BL - Feed-through terminal, Tension clamp connection, 2.5 mm², 800 V, 24 A, Blue ZDU 4 - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Dark Beige ZDU 4 BL - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Blue ZDU 6 - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A, Dark Beige ZDU 6 BL - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A,Blue ZDU 10 - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Dark Beige ZDU 10 BL - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Blue ZDU 16 - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Dark Beige ZDU 16 BL - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Blue Feed-through terminal blocks 2-Tier ZDK 2.5 - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Beige ZDK 2.5 BL - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Blue

Feed-through terminal blocks 1-tier ZDU 2.5 - Feed-through terminal, Tension clamp connection, 2.5 mm², 24 A, Dark Beige ZDU 2.5 BL - Feed-through terminal, Tension clamp connection, 2.5 mm², 800 V, 24 A, Blue ZDU 4 - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Dark Beige ZDU 4 BL - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Blue ZDU 6 - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A, Dark Beige ZDU 6 BL - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A,Blue ZDU 10 - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Dark Beige ZDU 10 BL - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Blue ZDU 16 - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Dark Beige ZDU 16 BL - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Blue Feed-through terminal blocks 2-Tier ZDK 2.5 - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Beige ZDK 2.5 BL - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Blue -

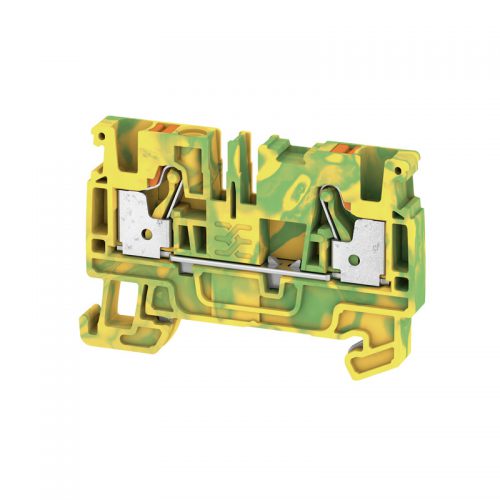

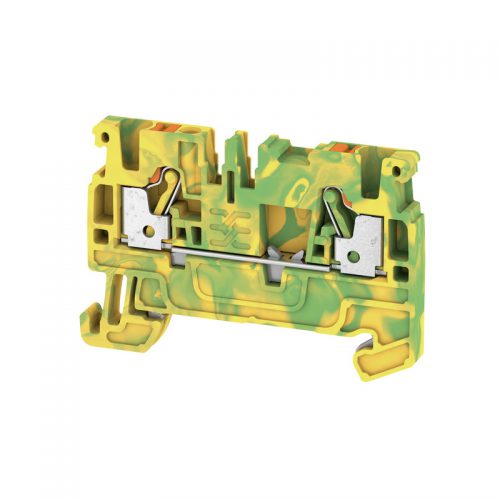

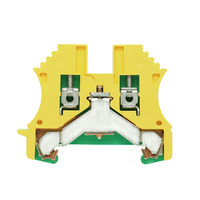

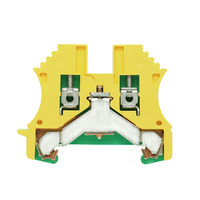

Modular PE terminal blocks 1 tier ZPE 2.5 - PE terminal, Tension clamp connection, 2.5 mm², 300 A (2.5 mm²), green / yellow ZPE 4 - PE terminal, Tension clamp connection, 4 mm², 480 A (4 mm²), green / yellow ZPE 6 - PE terminal, Tension clamp connection, 6 mm², 720 A (6 mm²), green / yellow ZPE 10 - PE terminal, Tension clamp connection, 10 mm², 1200 A (10 mm²), green / yellow ZPE 16 - PE terminal, Tension clamp connection, 16 mm², 1920 A (16 mm²), green / yellow ZPE 35 - PE terminal, Tension clamp connection, 35 mm², 4200 A (35 mm²), green / yellow Modular PE terminal blocks 2 tier ZDK 2.5 - Double-tier terminal, PE terminal, Tension clamp connection, 2.5 mm², 300 A (2.5 mm²), green / yellow

Modular PE terminal blocks 1 tier ZPE 2.5 - PE terminal, Tension clamp connection, 2.5 mm², 300 A (2.5 mm²), green / yellow ZPE 4 - PE terminal, Tension clamp connection, 4 mm², 480 A (4 mm²), green / yellow ZPE 6 - PE terminal, Tension clamp connection, 6 mm², 720 A (6 mm²), green / yellow ZPE 10 - PE terminal, Tension clamp connection, 10 mm², 1200 A (10 mm²), green / yellow ZPE 16 - PE terminal, Tension clamp connection, 16 mm², 1920 A (16 mm²), green / yellow ZPE 35 - PE terminal, Tension clamp connection, 35 mm², 4200 A (35 mm²), green / yellow Modular PE terminal blocks 2 tier ZDK 2.5 - Double-tier terminal, PE terminal, Tension clamp connection, 2.5 mm², 300 A (2.5 mm²), green / yellow -

DescriptionZSI ZSI 2.5

DescriptionZSI ZSI 2.5- Z-series, Fuse terminal, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

- Z-series, Fuse terminal with LED 28VAC, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

- Z-series, Fuse terminal with LED 120VAC, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

- Z-series, Fuse terminal with LED 250VAC, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

-

Description ZAP/TW1

Description ZAP/TW1- Z-series, Accessories, End plate, Seperation plate for ZDU 2.5,ZPE 2.5,ZTR2.5

- Z-series, Accessories, End plate, Seperation plate for ZDU 2.5 BL,ZTR 2.5 BL

- Z-series, Accessories, End plate, Seperation plate for ZSI 2.5, ZSI 2.5/LD 28 AC, ZSI 2.5/LD 120 AC, ZSI 2.5/LD250 AC,ZDU 2.5/2X2AN/D+,ZDU 2.5/2X2AN/D-

- Z-series, Accessories, End plate, Seperation plate for ZDU 4

- Z-series, Accessories, End plate, Seperation plate for ZDU 4 BL

- Z-series, Accessories, End plate, Seperation plate for ZDU 6, ZPE 6

- Z-series, Accessories, End plate, Seperation plate for ZDU 6 BL

- Z-series, Accessories, End plate, Seperation plate for ZDU 10, ZPE 10

- Z-series, Accessories, End plate, Seperation plate for ZDU 10 BL

- series, Accessories, End plate for ZDU 16, ZPE 16

- Z-series, Accessories, End plate for ZDU 16 BL

- Z-series, Accessories, End plate, Seperation plate for ZDK 2.5

- Z-series, Accessories, End plate, Seperation plate for ZDK 2.5 BL

-

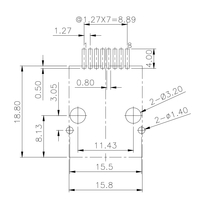

Description ZQV 2.5/10 GE

Description ZQV 2.5/10 GE- Z-series, Accessories,cross connection for ZDU 2.5, ZDK 2.5, ZTR 2.5 (10 poles)

- Z-series, Accessories,cross connection for ZDU 4(10 poles)

- Z-series, Accessories,cross connection for ZDU 6(24 poles)

- Z-series, Accessories,cross connection for ZDU 10(24poles)

- Z-series, Accessories,cross connection for ZDU 10( 2 poles)

- Z-series, Accessories,cross connection for ZDU 35 ( 2 poles)

-

Description TS 35X7.5/LL 2M/ST/ZN

Description TS 35X7.5/LL 2M/ST/ZN- Mounting rail, TS 35, TS 35 x 7.5, with slot, Steel, galvanized, chromium-plated

- Mounting rail, TS 35, TS 35 x 15, with slot, Steel, galvanized, chromium-plated

- Mounting rail, TS 35, TS 35 x 7.5, without slot, Stainless steel, untreated

-

Description WDU 2.5

Description WDU 2.5- Feed-through terminal, Screw connection, 2.5 mm², 800 V, 24 A, Dark Beige

- Feed-through terminal, Screw connection, 2.5 mm², 800 V, 24 A, Blue

- W-Series, Feed-through terminal, Thermocouple TYPE K, Rated cross-section: 2.5 mm², Screw connection

- Feed-through terminal, Screw connection, 4 mm², 800 V, 32 A, Dark Beige

- Feed-through terminal, Screw connection, 4 mm², 800 V, 32 A, Blue

- Feed-through terminal, Screw connection, 6 mm², 800 V, 41 A, Dark Beige

- Feed-through terminal, Screw connection, 6 mm², 800 V, 41 A, Blue

- Feed-through terminal, Screw connection, 10 mm², 1000 V, 57 A, Dark Beige

- Feed-through terminal, Screw connection, 10 mm², 1000 V, 57 A, Blue

- Feed-through terminal, Screw connection, 16 mm², 1000 V, 76 A, Dark Beige

- Feed-through terminal, Screw connection, 16 mm², 1000 V, 76 A, Blue

- Feed-through terminal, Screw connection, 35 mm², 1000 V, 125 A, Dark Beige

- Feed-through terminal, Screw connection, 35 mm², 1000 V, 125 A, Blue

- Feed-through terminal, Screw connection, 50 mm², 1000 V, 150 A, Dark Beige

- Feed-through terminal, Screw connection, 50 mm², 1000 V, 150 A, Blue

- Feed-through terminal, Screw connection, 70 mm², 1000 V, 192 A, Dark Beige

- Feed-through terminal, Screw connection, 70 mm², 1000 V, 192 A, Blue

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Dark Beige

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Blue

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Dark Beige

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Blue

- Feed-through terminal, Screw connection, 240 mm², 1000 V, 415 A, Dark Beige

- Feed-through terminal, Screw connection, 240 mm², 1000 V, 415 A, Blue

-

Description WDK 2.5

Description WDK 2.5- Feed-through terminal, Double-tier terminal, Screw connection, 2.5 mm², 400 V, 24 A, Dark Beige

- Feed-through terminal, Double-tier terminal, Screw connection, 2.5 mm², 400 V, 24 A, Blue

- Feed-through terminal, Double-tier terminal, Screw connection, 10 mm², 800 V, 57 A, Dark Beige

- Feed-through terminal, Double-tier terminal, Screw connection, 10 mm², 800 V, 57 A, Blue

-

Description WPE 2.5

Description WPE 2.5- PE terminal, Screw connection, 2.5 mm², 300 A (2.5 mm²), green / yellow

- PE terminal, Screw connection, 4 mm², 480 A (4 mm²), green / yellow

- PE terminal, Screw connection, 6 mm², 720 A (6 mm²), green / yellow

- PE terminal, Screw connection, 10 mm², 1200 A (10 mm²), green / yellow

- PE terminal, Screw connection, 16 mm², 1920 A (16 mm²), green / yellow

- PE terminal, Screw connection, 35 mm², 4200 A (35 mm²), green / yellow

- PE terminal, Screw connection, 50 mm², 6000 A (50 mm²), green / yellow

- PE terminal, Screw connection, 95 mm², 11400 A (95 mm²), green / yellow

- PE terminal, Screw connection, 95 mm², 11400 A (95 mm²), green / yellow

- PE terminal, Screw connection, 120 mm², 14400 A (120 mm²), green / yellow

-

Description WTR 2.5/SI

Description WTR 2.5/SI- W-Series, Fuse terminal, Rated cross-section: 2.5 mm², Screw connection

- W-Series, Fuse terminal, Rated cross-section: 4 mm², Screw connection

- W-Series, Fuse terminal with LED 10-36 VDC/AC, Rated cross-section: 4 mm², Screw connection

- W-Series, Fuse terminal with LED 140-250 VDC/AC, Rated cross-section: 4 mm², Screw connection

- W-Series, Fuse terminal, Rated cross-section: 6 mm², Screw connection, FUSE 5X20 mm

- W-Series, Fuse terminal with LED 10-36 VDC/AC, Rated cross-section: 6 mm², Screw connection, FUSE 5X20 mm

- W-Series, Fuse terminal with LED 250 AC, Rated cross-section: 6 mm², Screw connection, FUSE 5X20 mm

-

WTR 2.5

WTR 2.5- Test-disconnect terminal, Screw connection, 2.5 mm², 500 V, 24 A, Pivoting, Dark Beige

- Test-disconnect terminal, Screw connection, 2.5 mm², 500 V, 24 A, Pivoting, Blue

- Test-disconnect terminal, Screw connection, 4 mm², 400 V, 32 A, Pivoting, Dark Beige

- Test-disconnect terminal, Screw connection, 4 mm², 400 V, 32 A, Pivoting, Blue

-

Description WAP 2.5-10

Description WAP 2.5-10- W-Series, End plate for WDU 2.5 TO WDU 10, WTR 2.5,WSI 2.5/SI,WSI 6

- W-Series, End plate blue for WDU 2.5 BL TO WDU 10 BL, WTR 2.BL,WSI 6 BL

- W-Series, End plate for WDU 16 TO WDU35, WPE 16 TO WPE 35/ partition plate for WDU 2.5 TO WDU 10, WTR 2.5,WSI 6

- W-Series, End plate blue for WDU 16 TO WDU35, WPE 16 TO WPE 35/ partition plate for WDU 2.5 TO WDU 10, WTR 2.5,WSI 6

- W-Series, End plate for WDK 2.5, WDK 2.5 PE

- W-Series, End plate for WDK 2.5 BL

- W-Series, Seperation plate

- W-Series, End plate for WDK 10

- W-Series, End plate for WDK 10 BL

-

Description WQV 2.5/10 GE

Description WQV 2.5/10 GE- W-Series, Cross-connector, For the terminals WDU 2.5,WTR 2.5,WDK 2.5 No. of poles: 10

- W-Series, Cross-connector, For the terminals WDU 4, WTR 4, No. of poles: 10

- W-Series, Cross-connector, For the terminals WDU 6, No. of poles: 10

- W-Series, Cross-connector, For the terminals WDU 10, WDK 10, No. of poles: 10

- W-Series, Cross-connector, For the terminals WDU 16 No. of poles: 10

- W-Series, Cross-connector, For the terminals WDU 35, No. of poles: 10

- W-Series, Cross-connector, For the terminals WDU50N, No. of poles: 2

- W-Series, Cross-connector, For the terminals WDU70/95, No. of poles: 2

- W-Series, Cross-connector, For the terminals WDU95N/120N, No. of poles: 2

- W-Series, Cross-connector, For the terminals WDU 120/150, No. of poles: 2

-

Description TS 35X7.5/LL 2M/ST/ZN

Description TS 35X7.5/LL 2M/ST/ZN- Mounting rail, TS 35, TS 35 x 7.5, with slot, Steel, galvanized, chromium-plated

- Mounting rail, TS 35, TS 35 x 15, with slot, Steel, galvanized, chromium-platedTS

- Mounting rail, TS 35, TS 35 x 7.5, without slot, Stainless steel, untreated

-

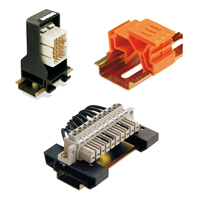

Description Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s

Description Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s -

Description Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s

Description Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s -

Description Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s

Description Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s -

RJ45 sockets Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s Industrial

RJ45 sockets Product range covers standing and flat designs, as well as versions with the latching hook at the top and bottom. • THT, THR or SMD soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s Industrial- Electronic

- Other

-

RJ45 sockets – transformer RJ45 transmitter sockets (magnetics) for gigabit applications (1000 base-T) with integrated compensation actively counteracts inductive and capacitive couplings and saves space on the PCB. • THT or THR soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s Industrial

RJ45 sockets – transformer RJ45 transmitter sockets (magnetics) for gigabit applications (1000 base-T) with integrated compensation actively counteracts inductive and capacitive couplings and saves space on the PCB. • THT or THR soldering processes • Wide range of different design types, also with integrated LEDs and shield contact tabs • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Extended temperature range of–40 °C to +85 °C • Reinforced gold layer for improved corrosion protection • Transmission rates of up to 1 Gbit/s Industrial- Electronic

- Other

-

USB plug-in connectors Universal serial bus 2.0 and 3.0 (SuperSpeed); Type A connectors meet the requirements for high resistance and provide reliable connectivity. • Up to 5000 plugging cycles • THT, THR or SMD soldering processes • Available in design types 180° (vertical/upright) or 90° (horizontal/flat-lying) • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Reinforced gold layer for improved corrosion protection

USB plug-in connectors Universal serial bus 2.0 and 3.0 (SuperSpeed); Type A connectors meet the requirements for high resistance and provide reliable connectivity. • Up to 5000 plugging cycles • THT, THR or SMD soldering processes • Available in design types 180° (vertical/upright) or 90° (horizontal/flat-lying) • Packed either in a tray (TY) or on a roll (tape-on-reel, RL) • Reinforced gold layer for improved corrosion protection -

Clamping yoke screw connection The undisputed no. 1 in screw connection technology - billions of tried and tested, internationally recognised, completely maintenance-free components: Circuit board terminals with clamping yoke screw connection - the market standard by Weidmüller. Continually growing: the most extensive range of terminals on the market: 6 connection cross-sections from 0.08 to 25mm² Maximum current-carrying capacity of 101A at ambient temperatures of 40° (IEC) 3 conductor outlet directions (90 / 135 / 180°) Single level and multi level enclosure Reliability personified: 100% versatile - clamping range < 0,2mm ...>15 mm² 100% flexible - for solid or flexible conductors, also without AEH 100% maintenance-free due to self-locking screw retention device 100% reliable contact - gas-tight and vibration-proof Specific material selection: steel for strength and copper for conductivity. Widely recognised and guaranteed reliability - the indispensable connection system compatible with every device series. Industrial

Clamping yoke screw connection The undisputed no. 1 in screw connection technology - billions of tried and tested, internationally recognised, completely maintenance-free components: Circuit board terminals with clamping yoke screw connection - the market standard by Weidmüller. Continually growing: the most extensive range of terminals on the market: 6 connection cross-sections from 0.08 to 25mm² Maximum current-carrying capacity of 101A at ambient temperatures of 40° (IEC) 3 conductor outlet directions (90 / 135 / 180°) Single level and multi level enclosure Reliability personified: 100% versatile - clamping range < 0,2mm ...>15 mm² 100% flexible - for solid or flexible conductors, also without AEH 100% maintenance-free due to self-locking screw retention device 100% reliable contact - gas-tight and vibration-proof Specific material selection: steel for strength and copper for conductivity. Widely recognised and guaranteed reliability - the indispensable connection system compatible with every device series. Industrial- Electronic

- Other

-

TOP-screw connection Screw connection with optimised design - easy to use and minimum space requirements br /> TOP GS PCB terminal system with TOP screw connection. Operated from one side only. Optional: ATEX approval. Operated from one side and extremely versatile: · High current-carrying capacity up to 32 A (IEC) or 30 A (UL) · 3 pitches (5.08 / 6.35 / 7.62 mm) for voltages up to 1000V (IEC) or 300 V (UL) · Enormous connection capacity, cross-sections up to 6 mm² · 2 outlet directions in relation to the PCB (90 / 180°) · For mounting side by side or fixed number of poles, up to 24 connections · Explosion-protected variations for ATEX zones · Attachment profile for Dekafix markers Sophisticated design and user-friendly wiring - conductor connected and the clamping point accessed from the same direction (TOP) TOP GS: the special terminal for special applications. Industrial

TOP-screw connection Screw connection with optimised design - easy to use and minimum space requirements br /> TOP GS PCB terminal system with TOP screw connection. Operated from one side only. Optional: ATEX approval. Operated from one side and extremely versatile: · High current-carrying capacity up to 32 A (IEC) or 30 A (UL) · 3 pitches (5.08 / 6.35 / 7.62 mm) for voltages up to 1000V (IEC) or 300 V (UL) · Enormous connection capacity, cross-sections up to 6 mm² · 2 outlet directions in relation to the PCB (90 / 180°) · For mounting side by side or fixed number of poles, up to 24 connections · Explosion-protected variations for ATEX zones · Attachment profile for Dekafix markers Sophisticated design and user-friendly wiring - conductor connected and the clamping point accessed from the same direction (TOP) TOP GS: the special terminal for special applications. Industrial- Electronic

- Other

-

PUSH IN spring connection The innovative quick connector - simple, safe and economical: PCB terminals with spring connection and direct PUSH IN technology. A milestone in connection technology. Amazingly simple and simply amazing in practice: Connect and easily detach solid wires or wires with wire-end ferrules without using tools Processed automatically in the reflow or vapour phase Potentials and clamping points marked clearly by coloured push buttons World-class design-in and processing phases, and suitable for a vast range of applications. Industrial

PUSH IN spring connection The innovative quick connector - simple, safe and economical: PCB terminals with spring connection and direct PUSH IN technology. A milestone in connection technology. Amazingly simple and simply amazing in practice: Connect and easily detach solid wires or wires with wire-end ferrules without using tools Processed automatically in the reflow or vapour phase Potentials and clamping points marked clearly by coloured push buttons World-class design-in and processing phases, and suitable for a vast range of applications. Industrial- Electronic

- Other

-

Tension clamp spring connection Weidmüller tension-clamp connections - simple, quick and proven reliable: The universal screw-free connection with steel spring – ideal for PCB installation terminals. Wiring with demanding requirements for cost-effective connections with contact stability. Industrial

Tension clamp spring connection Weidmüller tension-clamp connections - simple, quick and proven reliable: The universal screw-free connection with steel spring – ideal for PCB installation terminals. Wiring with demanding requirements for cost-effective connections with contact stability. Industrial- Electronic

- Other

-

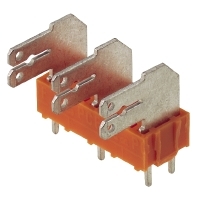

Flat-blade connection The traditional single-wire connection – versatile, simple and cost-effective: PCB terminals with cable-lug connection – the PCF system. High current-carrying capacity up to 24 A (IEC) or 15 A (UL) 3 pitches (5.0 / 7.5 / 10.0 mm) for voltages up to 1000 V (IEC) or 300 V (UL) 3 outlet directions in relation to the PCB (90 / 135 / 180°) For mounting side by side or fixed number of poles, between 2 and 19 connector lugs Can be used with 2.8 and 6.3 mm flat blade receptacles Suitable for insulated and uninsulated receptacles For applications requiring the quick and easy connection of pre-assembled conductors to PCBs. A simple solution for simple connections: inexpensive Faston connection system for PCBs. Industrials

Flat-blade connection The traditional single-wire connection – versatile, simple and cost-effective: PCB terminals with cable-lug connection – the PCF system. High current-carrying capacity up to 24 A (IEC) or 15 A (UL) 3 pitches (5.0 / 7.5 / 10.0 mm) for voltages up to 1000 V (IEC) or 300 V (UL) 3 outlet directions in relation to the PCB (90 / 135 / 180°) For mounting side by side or fixed number of poles, between 2 and 19 connector lugs Can be used with 2.8 and 6.3 mm flat blade receptacles Suitable for insulated and uninsulated receptacles For applications requiring the quick and easy connection of pre-assembled conductors to PCBs. A simple solution for simple connections: inexpensive Faston connection system for PCBs. Industrials- Electronic

- Other

-

Accessories Integrate, expand and customise: the perfect supplement to every application. Universal system accessories enable easy adaptation of the interfaces to fulfil specific requirements for the relevant application. The following options are available depending on the system: installing and fastening components Signalling and checking statuses Marking and labelling components Potential distribution and separation Only the right high-quality tools will ensure professional working standards. All in all: ease of operation, maximum functionality and safety for the application and the user. Industrial

Accessories Integrate, expand and customise: the perfect supplement to every application. Universal system accessories enable easy adaptation of the interfaces to fulfil specific requirements for the relevant application. The following options are available depending on the system: installing and fastening components Signalling and checking statuses Marking and labelling components Potential distribution and separation Only the right high-quality tools will ensure professional working standards. All in all: ease of operation, maximum functionality and safety for the application and the user. Industrial- Electronic

- Other

-

The pluggable PCB connection is the established standard in process and manufacturing automation as well as the measurement and control industry.

The pluggable PCB connection is the established standard in process and manufacturing automation as well as the measurement and control industry.- The wide line with many product series, provides design flexibility, efficient processing and safe, intuitive handling: 36 connections at 3.50 mm pitch, highest level of power reserves in 3.81 mm pitch and the largest application area in 5.08 mm pitch

- Application-oriented connection systems, from clamping-yoke screw connections to PUSH-IN spring connections

- A wide range of reflow compatible products for automated SMT processes

- Multi-row and multi-layer designs up to 48-pole

-

'PUSH IN - Weidmüller's innovative connection system simplifies the wire connection process. The benefits for users and applications: High component density because of small pitch. Simply insert the prepared wire - and you're done Simplified processing, thanks to integrated push buttons for opening the terminal point Intuitive handling – since the conductor entry and handling areas are clearly separated

'PUSH IN - Weidmüller's innovative connection system simplifies the wire connection process. The benefits for users and applications: High component density because of small pitch. Simply insert the prepared wire - and you're done Simplified processing, thanks to integrated push buttons for opening the terminal point Intuitive handling – since the conductor entry and handling areas are clearly separated -

Two-row female plug with PUSH IN spring connection · the wire-entry area and handling area are clearly separated · Integrated push-buttons for opening the terminal point · High component density because of low heights · Optional: locking and releasing require no tools when using Weidmüller's · release latch (LR) or release lever (LH)

Two-row female plug with PUSH IN spring connection · the wire-entry area and handling area are clearly separated · Integrated push-buttons for opening the terminal point · High component density because of low heights · Optional: locking and releasing require no tools when using Weidmüller's · release latch (LR) or release lever (LH) -

The SC pin header has a perpendicular (standing) plugging direction in relation to the PCB. It is available in closed (G) and screw flange (F) versions. Weidmüller's 3.81-mm-pitch (0.15 inch) plug-in connectors are compatible with the layouts of standard connectors and offer space for labelling and coding.

The SC pin header has a perpendicular (standing) plugging direction in relation to the PCB. It is available in closed (G) and screw flange (F) versions. Weidmüller's 3.81-mm-pitch (0.15 inch) plug-in connectors are compatible with the layouts of standard connectors and offer space for labelling and coding. -

SL-SMT 5.08HC/270 High-temperature-resistant, straight, open pin header. Packed in box or tape. On tape and with 1.5 mm solder pin, optimised for automatic assembly. 3.2 mm solder pin suitable for reflow and wave soldering. The pin headers provide space for labelling and can be coded. HC = High Current.

SL-SMT 5.08HC/270 High-temperature-resistant, straight, open pin header. Packed in box or tape. On tape and with 1.5 mm solder pin, optimised for automatic assembly. 3.2 mm solder pin suitable for reflow and wave soldering. The pin headers provide space for labelling and can be coded. HC = High Current. -

RSV 1.6 C Rectangular plug-in connector for use with crimp contacts. Can be used as universal coupling, but also with the PCB variations. The crimp contacts guarantee a high connection density. CS 1.6 or CB 1.6 contacts can be used here. The plug-in connectors can be coded and locked to the mating connector. Supplied in cardboard box.

RSV 1.6 C Rectangular plug-in connector for use with crimp contacts. Can be used as universal coupling, but also with the PCB variations. The crimp contacts guarantee a high connection density. CS 1.6 or CB 1.6 contacts can be used here. The plug-in connectors can be coded and locked to the mating connector. Supplied in cardboard box. -

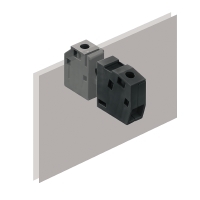

Adapters for rail mounting From the circuit board in the control cabinet: snap-on or mounting feet form the link between plug-in connectors and terminal rails. Compatible with all standard sizes: TS 15 or TS 35. Combination foot or variations available. The quick alternative to screw connections: unbeatable ease of installation and service. The mounting foot for the terminal rails allows the universal use of pluggable connection systems on the module, the enclosure and the control cabinet and avoids patchwork solutions.

Adapters for rail mounting From the circuit board in the control cabinet: snap-on or mounting feet form the link between plug-in connectors and terminal rails. Compatible with all standard sizes: TS 15 or TS 35. Combination foot or variations available. The quick alternative to screw connections: unbeatable ease of installation and service. The mounting foot for the terminal rails allows the universal use of pluggable connection systems on the module, the enclosure and the control cabinet and avoids patchwork solutions. -

The sturdy, direct connection for extreme current and voltage requirements in all power electronics applications such as solar inverters, frequency converters, servo-controllers and power supplies. Expect more than just PCB terminals: · High-power: 150 A / 1000 V (IEC) or 127 A / 600 V (UL) · Application-oriented scalability: connection cross-sections from 16 mm² to 50 mm² · Simple UL approval of the device up to 600 V · Zero-maintenance steel clamp for screw connections that are resistant to vibration

The sturdy, direct connection for extreme current and voltage requirements in all power electronics applications such as solar inverters, frequency converters, servo-controllers and power supplies. Expect more than just PCB terminals: · High-power: 150 A / 1000 V (IEC) or 127 A / 600 V (UL) · Application-oriented scalability: connection cross-sections from 16 mm² to 50 mm² · Simple UL approval of the device up to 600 V · Zero-maintenance steel clamp for screw connections that are resistant to vibration -

Clamping yoke screw connection The sturdy, direct connection for extreme current and voltage requirements in all power electronics applications such as solar inverters, frequency converters, servo-controllers and power supplies. Expect more than just PCB terminals: · High-power: 150 A / 1000 V (IEC) or 127 A / 600 V (UL) · Application-oriented scalability: connection cross-sections from 16 mm² to 50 mm² · Simple UL approval of the device up to 600 V · Zero-maintenance steel clamp for screw connections that are resistant to vibration Industrial

Clamping yoke screw connection The sturdy, direct connection for extreme current and voltage requirements in all power electronics applications such as solar inverters, frequency converters, servo-controllers and power supplies. Expect more than just PCB terminals: · High-power: 150 A / 1000 V (IEC) or 127 A / 600 V (UL) · Application-oriented scalability: connection cross-sections from 16 mm² to 50 mm² · Simple UL approval of the device up to 600 V · Zero-maintenance steel clamp for screw connections that are resistant to vibration Industrial- Electronic

- Other

-

OMNIMATE Power BV / SV 7.62HP Hybrid – for power, signals and EMC Three functions in one. The OMNIMATE Power Hybrid connector provides developers and users with the perfect three-in-one solution. This hybrid motor connector simultaneously unites power, signals and pluggable EMC shield support. Thus you save space on the PCB, on the outer side of the housing, and in the electrical cabinet. The self-snapping one-handed interlock mechanism requires only one plugging step and thus speeds up installation and maintenance procedures. It is easy to handle and interlocks automatically – even in difficult installation positions. The unique shielding shape and slender 30° wire entry enable a space savings of up to 10 cm between rows. Industrial

OMNIMATE Power BV / SV 7.62HP Hybrid – for power, signals and EMC Three functions in one. The OMNIMATE Power Hybrid connector provides developers and users with the perfect three-in-one solution. This hybrid motor connector simultaneously unites power, signals and pluggable EMC shield support. Thus you save space on the PCB, on the outer side of the housing, and in the electrical cabinet. The self-snapping one-handed interlock mechanism requires only one plugging step and thus speeds up installation and maintenance procedures. It is easy to handle and interlocks automatically – even in difficult installation positions. The unique shielding shape and slender 30° wire entry enable a space savings of up to 10 cm between rows. Industrial- Electronic

-

OMNIMATE Power for IT networks – scalable to 50 kVA Tailor-made solutions for special requirements More standard-compliance means fewer compromises: OMNIMATE Power for IT networks has integrated features incorporated as standard across the range. This makes the design-in and approvals process simpler and makes them safer and more reliable in operation. Results for the application and advantages for the user: unlimited use in 400-V IT systems and touch safety according to IEC 61800-5-1 (+ 5.5 mm). The self-snapping one-handed safety flange enables intuitive and safe usage. Operational reliability is guaranteed by the automatic interlock feature during the plug-in process. In conclusion: You need no additional device covering. The application-oriented design means that no compromises are necessary during the approval process. Industrial

OMNIMATE Power for IT networks – scalable to 50 kVA Tailor-made solutions for special requirements More standard-compliance means fewer compromises: OMNIMATE Power for IT networks has integrated features incorporated as standard across the range. This makes the design-in and approvals process simpler and makes them safer and more reliable in operation. Results for the application and advantages for the user: unlimited use in 400-V IT systems and touch safety according to IEC 61800-5-1 (+ 5.5 mm). The self-snapping one-handed safety flange enables intuitive and safe usage. Operational reliability is guaranteed by the automatic interlock feature during the plug-in process. In conclusion: You need no additional device covering. The application-oriented design means that no compromises are necessary during the approval process. Industrial- Electronic

- Other

-

OMNIMATE Power HP The pluggable connections for power electronics - optimised for modern drive technologies, e.g. motor starters, frequency converters and servo-controllers. OMNIMATE Power sets the new standard – with increased safety and innovative solutions such as the pluggable shield, integrated signal contacts and one-handed operation. The three product lines offer you further advantages: · Application-oriented scalability: from the compact 4 mm² connector for 29 A (IEC) or 20 A (UL) up to the sturdy 16 mm² connector for 76 A (IEC) or 54 A (UL) · Unlimited usage up to 1,000 V (IEC) or 600 V (UL) · A variety of application optimised mounting options Industrial

OMNIMATE Power HP The pluggable connections for power electronics - optimised for modern drive technologies, e.g. motor starters, frequency converters and servo-controllers. OMNIMATE Power sets the new standard – with increased safety and innovative solutions such as the pluggable shield, integrated signal contacts and one-handed operation. The three product lines offer you further advantages: · Application-oriented scalability: from the compact 4 mm² connector for 29 A (IEC) or 20 A (UL) up to the sturdy 16 mm² connector for 76 A (IEC) or 54 A (UL) · Unlimited usage up to 1,000 V (IEC) or 600 V (UL) · A variety of application optimised mounting options Industrial- Electronic

- Other

-

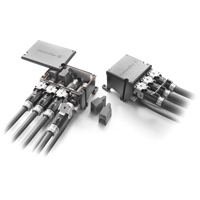

Feedthrough terminals for devices - OMNIMATE Power The universal solution to feed power through housing walls. Excellent for applications such as EMC filters, discrete-built inverters for drive systems and encapsulated devices. Select from our wide-ranging programme: · 4 mm²A wide service portfolio for currents up to 232 A and conductor cross-sections from 4 to 95 mm² (AWG 4/0) · Different types of connections such as a castable soldering connection, cable lug bolt connection and service-free clamping yoke screw connection and PUSH IN spring connection · Structural shapes for horizontal or vertical outgoing cable Industrial

Feedthrough terminals for devices - OMNIMATE Power The universal solution to feed power through housing walls. Excellent for applications such as EMC filters, discrete-built inverters for drive systems and encapsulated devices. Select from our wide-ranging programme: · 4 mm²A wide service portfolio for currents up to 232 A and conductor cross-sections from 4 to 95 mm² (AWG 4/0) · Different types of connections such as a castable soldering connection, cable lug bolt connection and service-free clamping yoke screw connection and PUSH IN spring connection · Structural shapes for horizontal or vertical outgoing cable Industrial- Electronic

- Other

-

6 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. The innovative PUSH IN connection system from Weidmüller makes for a simple, tool-free wire connection on the inside and outside of devices. The sliced design and an intuitive fastening mechanism enable high-density blocks to be constructed quickly and easily. Industrial

6 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. The innovative PUSH IN connection system from Weidmüller makes for a simple, tool-free wire connection on the inside and outside of devices. The sliced design and an intuitive fastening mechanism enable high-density blocks to be constructed quickly and easily. Industrial- Electronic

- Other

-

10 mm² : Optimal connection options for use in encapsulated devices (e.g. EMC filters and/or fully insulated transformers) The V versions of the WGK feed-through terminals with an insulated housing and clamping yoke connection on the outside, and a solder connection on the inside. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial

10 mm² : Optimal connection options for use in encapsulated devices (e.g. EMC filters and/or fully insulated transformers) The V versions of the WGK feed-through terminals with an insulated housing and clamping yoke connection on the outside, and a solder connection on the inside. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial- Electronic

- Other

-

16 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. Different types of connection on the inside, such as a solder connection which can be encapsulated (WGK …VP) or a maintenance-free clamping yoke screw connection (WGK…) with vertical and horizontal wire connections, provide the optimal connection for any installation situation. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial

16 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. Different types of connection on the inside, such as a solder connection which can be encapsulated (WGK …VP) or a maintenance-free clamping yoke screw connection (WGK…) with vertical and horizontal wire connections, provide the optimal connection for any installation situation. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial- Electronic

- Other

-

25 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. Various types of connection on the inside, such as cable lug connections which can be encapsulated (WGK …VP) and maintenance-free clamping yoke screw connections (WGK…) with vertical and horizontal wire insertion provide the optimal connection for any installation situation. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial

25 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. Various types of connection on the inside, such as cable lug connections which can be encapsulated (WGK …VP) and maintenance-free clamping yoke screw connections (WGK…) with vertical and horizontal wire insertion provide the optimal connection for any installation situation. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial- Electronic

- Other

-

Sample set - OMNIMATE OMNIMATE Signal and OMNIMATE Power are PCB terminal blocks, plug-in connector and panel feedthrough terminal blocks for industrial applications with a focus on signal processing and power electronics. Power for high currents up to 232 A and voltages up to 1000 V (IEC) or 230 A at 600 V (UL). The components are optimised for application-oriented design, efficient production and reliable application. OMNIMATE Data are RJ45 and USB circuit board sockets for safe data transmission in the Industrial Ethernet environment. RJ45 components from Weidmüller ensure reliable transmission with high data rates up to 1 Gbit/s. With different variants for THT, THR or SMT solder processes, the female sockets are suitable for all common techniques of PCB assembly. The different design types of the RJ45 circuit board sockets allow adaptation to the individual enclosure design. Industrial

Sample set - OMNIMATE OMNIMATE Signal and OMNIMATE Power are PCB terminal blocks, plug-in connector and panel feedthrough terminal blocks for industrial applications with a focus on signal processing and power electronics. Power for high currents up to 232 A and voltages up to 1000 V (IEC) or 230 A at 600 V (UL). The components are optimised for application-oriented design, efficient production and reliable application. OMNIMATE Data are RJ45 and USB circuit board sockets for safe data transmission in the Industrial Ethernet environment. RJ45 components from Weidmüller ensure reliable transmission with high data rates up to 1 Gbit/s. With different variants for THT, THR or SMT solder processes, the female sockets are suitable for all common techniques of PCB assembly. The different design types of the RJ45 circuit board sockets allow adaptation to the individual enclosure design. Industrial- Electronic

- Other

-

RockStar® heavy duty connectors Currently, heavy-duty connectors are used wherever there is a need for a secure, simple and time-saving assembly of machinery and facilities. The connector housings are made of die-cast aluminium and offer excellent protection against dirt, moisture and mechanical stress. Special modular connectors make it possible to integrate signals, power supply and data connections into a single connector. With the RockStar® heavy-duty connectors, Weidmüller offers a product line with many patented innovations that is oriented towards the future. The RockStar® product line defines new standards with the comprehensive depth and width of its features. What other suppliers offer only as a custom configuration, Weidmüller supplies in its standard product line. As a result, selecting the proper connector is now easier than ever. You save both time and money. And your work flow is optimised. Thus you can strengthen your position on the market and leverage your competitive advantage Industrial

RockStar® heavy duty connectors Currently, heavy-duty connectors are used wherever there is a need for a secure, simple and time-saving assembly of machinery and facilities. The connector housings are made of die-cast aluminium and offer excellent protection against dirt, moisture and mechanical stress. Special modular connectors make it possible to integrate signals, power supply and data connections into a single connector. With the RockStar® heavy-duty connectors, Weidmüller offers a product line with many patented innovations that is oriented towards the future. The RockStar® product line defines new standards with the comprehensive depth and width of its features. What other suppliers offer only as a custom configuration, Weidmüller supplies in its standard product line. As a result, selecting the proper connector is now easier than ever. You save both time and money. And your work flow is optimised. Thus you can strengthen your position on the market and leverage your competitive advantage Industrial- Machinery

-

Inserts A heavy-duty connector consists of a connector insert and its protective housing. The insert is therefore the heart of the heavy-duty connector. It is responsible for electrical functioning. Connector inserts from Weidmüller are made from high-quality insulation materials, which allow secure transmission of high voltages in a tight space. Moreover, we use only a single type of plastic in our entire product line. This plastic is UL listed, and suitable for railway applications. This allows unlimited world-wide use of the RockStar® connector. Industrial

Inserts A heavy-duty connector consists of a connector insert and its protective housing. The insert is therefore the heart of the heavy-duty connector. It is responsible for electrical functioning. Connector inserts from Weidmüller are made from high-quality insulation materials, which allow secure transmission of high voltages in a tight space. Moreover, we use only a single type of plastic in our entire product line. This plastic is UL listed, and suitable for railway applications. This allows unlimited world-wide use of the RockStar® connector. Industrial- Machinery

-

RockStar® ModuPlug Make your connections fit for the future With the advanced solutions from RockStar® ModuPlug Industrial applications are becoming increasingly complex. The demands being made of the connectivity used are growing at the same time. Functionality in the smallest of installation spaces, safe installation and a fast retrofitting process are just some of the product properties being called for. Not only does our RockStar® ModuPlug modular plug-in connector system meet current market requirements; it has been specially designed with the future in mind too. Using the individual modules, you combine all the necessary functions for power, signal and data transmission in a single interface. Thanks to the new variety of module sizes, you can fit more applications than ever before in one plug-in connector. The modules reduce the amount of space required and cut costs when compared with fixed-pole inserts and other modular plug-in connector systems. The sophisticated frames and modules can be installed with extreme ease and integrated into HDC enclosures with the IP65 and IP68 protection classes. You can even use the RockStar® ModuPlug to supplement existing applications without any need to make system adjustments. As an experienced Industrial Connectivity partner, Weidmüller offers ultra-modern connectivity with maximum reliability. So you can create customised solutions for future-proof connections with RockStar® too. Industrial

RockStar® ModuPlug Make your connections fit for the future With the advanced solutions from RockStar® ModuPlug Industrial applications are becoming increasingly complex. The demands being made of the connectivity used are growing at the same time. Functionality in the smallest of installation spaces, safe installation and a fast retrofitting process are just some of the product properties being called for. Not only does our RockStar® ModuPlug modular plug-in connector system meet current market requirements; it has been specially designed with the future in mind too. Using the individual modules, you combine all the necessary functions for power, signal and data transmission in a single interface. Thanks to the new variety of module sizes, you can fit more applications than ever before in one plug-in connector. The modules reduce the amount of space required and cut costs when compared with fixed-pole inserts and other modular plug-in connector systems. The sophisticated frames and modules can be installed with extreme ease and integrated into HDC enclosures with the IP65 and IP68 protection classes. You can even use the RockStar® ModuPlug to supplement existing applications without any need to make system adjustments. As an experienced Industrial Connectivity partner, Weidmüller offers ultra-modern connectivity with maximum reliability. So you can create customised solutions for future-proof connections with RockStar® too. Industrial- Machinery

-

Housing A heavy-duty connector consists of a connector insert and its protective housing. All of Weidmüller's RockStar® housings are made of high-quality die-cast aluminium. Thus they are impact- and corrosion-resistant, yet compact and lightweight. Their patented stainless steel clips make them totally water- and dust-proof. They can be used under the harshest environmental conditions and are resistant to frost and vibrations. Industrial

Housing A heavy-duty connector consists of a connector insert and its protective housing. All of Weidmüller's RockStar® housings are made of high-quality die-cast aluminium. Thus they are impact- and corrosion-resistant, yet compact and lightweight. Their patented stainless steel clips make them totally water- and dust-proof. They can be used under the harshest environmental conditions and are resistant to frost and vibrations. Industrial- Machinery

-

Crimp contacts The heart of a connector is its contacts. They make up the actual connection between two conductors. For this purpose, two contact types are necessary - plugs and sockets. The plug (male) implements the electrical connection along its outer surface. It is inserted into the socket, which conducts the electrical connection along the surface of its interior side. Weidmüller offers crimp contacts made with different surfaces: gold or silver. Industrial

Crimp contacts The heart of a connector is its contacts. They make up the actual connection between two conductors. For this purpose, two contact types are necessary - plugs and sockets. The plug (male) implements the electrical connection along its outer surface. It is inserted into the socket, which conducts the electrical connection along the surface of its interior side. Weidmüller offers crimp contacts made with different surfaces: gold or silver. Industrial- Machinery

-

Kits The RockStar® kits normally consist of a male insert, a female insert, a plug housing, a bulkhead housing and a cable gland. Weidmüller offers a range of standard plug-in connector combinations with metric or PG cable entry threads, with screw connection or PUSH IN connection. Industrial

Kits The RockStar® kits normally consist of a male insert, a female insert, a plug housing, a bulkhead housing and a cable gland. Weidmüller offers a range of standard plug-in connector combinations with metric or PG cable entry threads, with screw connection or PUSH IN connection. Industrial- Machinery

-

HighPower Kits The RockStar® HighPower housings are manufactured from high-strength die-cast aluminium and offer perfect protection against harsh environmental conditions thanks to continual optimisation. The multi-part housing gives users the opportunity to examine work processes down to the last step in the workflow. Industrial

HighPower Kits The RockStar® HighPower housings are manufactured from high-strength die-cast aluminium and offer perfect protection against harsh environmental conditions thanks to continual optimisation. The multi-part housing gives users the opportunity to examine work processes down to the last step in the workflow. Industrial- Machinery

-

HighPower accessories The RockStar® HighPower housings are manufactured from high-strength die-cast aluminium and offer perfect protection against harsh environmental conditions thanks to continual optimisation. The multi-part housing gives users the opportunity to examine work processes down to the last step in the workflow. Industrial

HighPower accessories The RockStar® HighPower housings are manufactured from high-strength die-cast aluminium and offer perfect protection against harsh environmental conditions thanks to continual optimisation. The multi-part housing gives users the opportunity to examine work processes down to the last step in the workflow. Industrial- Machinery

-

HighPower end-wall connector The RockStar® HighPower system, with its completely newly developed and coordinated components in three and four pin versions, represents a novel product solution for pluggable energy transmission – failure-free The RockStar® HighPower system has a modular design and offers the customer a multitude of product solutions for all kinds of application sites and requirements. The RockStar® HighPower end-wall connector is impact-resistant, water and dust-proof and was built to comply with DIN EN 61373 CAT 1b (bogie) requirements. The overall structure has been adapted to the confined space of wagon-to-wagon coupling - small, light and powerful Industrial

HighPower end-wall connector The RockStar® HighPower system, with its completely newly developed and coordinated components in three and four pin versions, represents a novel product solution for pluggable energy transmission – failure-free The RockStar® HighPower system has a modular design and offers the customer a multitude of product solutions for all kinds of application sites and requirements. The RockStar® HighPower end-wall connector is impact-resistant, water and dust-proof and was built to comply with DIN EN 61373 CAT 1b (bogie) requirements. The overall structure has been adapted to the confined space of wagon-to-wagon coupling - small, light and powerful Industrial- Machinery

-

HighPower housings The RockStar® HighPower housings are manufactured from high-strength die-cast aluminium and offer perfect protection against harsh environmental conditions thanks to continual optimisation. The multi-part housing gives users the opportunity to examine work processes down to the last step in the workflow. Industrial

HighPower housings The RockStar® HighPower housings are manufactured from high-strength die-cast aluminium and offer perfect protection against harsh environmental conditions thanks to continual optimisation. The multi-part housing gives users the opportunity to examine work processes down to the last step in the workflow. Industrial- Machinery

-

Tools Weidmüller's professional tools are the result of an intensive development process that has been specifically focussed on the requirements of their use in practice. We offer many useful tools, e.g. no-contact tools, crimping pliers and fibre optic tools, that help you work safely and precisely for an optimised installation of heavy-duty connectors. Industrial

Tools Weidmüller's professional tools are the result of an intensive development process that has been specifically focussed on the requirements of their use in practice. We offer many useful tools, e.g. no-contact tools, crimping pliers and fibre optic tools, that help you work safely and precisely for an optimised installation of heavy-duty connectors. Industrial- Machinery

-

ELECTRONIC The Electronics Department develops and markets electronic components for industrial automation, process automation and energy production. These components are used both inside and outside of the electrical cabinet. The focus of the electronics sector is on processing digital and analogue signals. These signals can be converted, standardised, protected and prepared for communication. For these purposes, we offer signal converters and input/output devices for Fieldbus communications based on Industrial Ethernet and Fieldbus. Product solutions are also available for the following fields: surge protection, protecting and amplifying digital signals, supplying devices inside and outside of the electrical cabinet, Ethernet data communication and for pre-assembled system cables. All of these products feature a mechanically convenient installation process, an optimised handling of electrical connections and safe wire connections. The products themselves are well suited for harsh industrial applications. They are suitable for use in a large range of operating temperatures and feature excellent resistance against electromagnetic interference. With this portfolio, the Electronics Department features products which cover the full industrial applications spectrum for the transferring and conditioning of power, signals and data.

ELECTRONIC The Electronics Department develops and markets electronic components for industrial automation, process automation and energy production. These components are used both inside and outside of the electrical cabinet. The focus of the electronics sector is on processing digital and analogue signals. These signals can be converted, standardised, protected and prepared for communication. For these purposes, we offer signal converters and input/output devices for Fieldbus communications based on Industrial Ethernet and Fieldbus. Product solutions are also available for the following fields: surge protection, protecting and amplifying digital signals, supplying devices inside and outside of the electrical cabinet, Ethernet data communication and for pre-assembled system cables. All of these products feature a mechanically convenient installation process, an optimised handling of electrical connections and safe wire connections. The products themselves are well suited for harsh industrial applications. They are suitable for use in a large range of operating temperatures and feature excellent resistance against electromagnetic interference. With this portfolio, the Electronics Department features products which cover the full industrial applications spectrum for the transferring and conditioning of power, signals and data. -

Analogue signal processing When used for industrial monitoring applications, sensors can record ambience conditions. Sensor signals are used within the process to continually track changes to the area being monitored. Both digital and analogue signals can occur. Normally an electrical voltage or current value is produced which corresponds proportionally to the physical variables that are being monitored Analogue signal processing is required when automation processes have to constantly maintain or reach defined conditions. This is particularly significant for process automation applications. Standardised electrical signals are typically used for process engineering. Analogue standardised currents / voltage 0(4)...20 mA/ 0...10 V have established themselves as physical measurement and control variables. Weidmüller meets the ever increasing challenges of automation and offers a product portfolio tailored to the requirements of handling sensor signals in analogue signal processing The analogue signal processing products can be used universally in combination with other Weidmüller products and in combination among each other. Their electrical and mechanical design is such that they require only minimal wiring efforts. Housing types and wire-connection methods matched to the respective application facilitate the universal use in process and industrial automation applications. The product line includes the following functions: Isolating transformers, supply isolators and signal converters for DC standard signals Temperature measuring transducers for resistance thermometers and thermocouples, frequency converters, potentiometer-measuring-transducers, bridge measuring transducers (strain gauges) trip amplifiers and modules for monitoring electrical and non-electrical process variables AD/DA converters displays calibration devices The products mentioned are available as pure signal converters / isolation transducers, 2-way/3-way isolators, supply isolators, passive isolators or as trip amplifiers. When used for industrial monitoring applications, sensors can record ambience conditions. Sensor signals are used within the process to continually track changes to the area being monitored. Both digital and analogue signals can occur. Normally an electrical voltage or current value is produced which corresponds proportionally to the physical variables that are being monitored Analogue signal processing is required when automation processes have to constantly maintain or reach defined conditions. This is particularly significant for process automation applications. Standardised electrical signals are typically used for process engineering. Analogue standardised currents / voltage 0(4)...20 mA/ 0...10 V have established themselves as physical measurement and control variables. Weidmüller meets the ever increasing challenges of automation and offers a product portfolio tailored to the requirements of handling sensor signals in analogue signal processing The analogue signal processing products can be used universally in combination with other Weidmüller products and in combination among each other. Their electrical and mechanical design is such that they require only minimal wiring efforts. Housing types and wire-connection methods matched to the respective application facilitate the universal use in process and industrial automation applications. The product line includes the following functions: Isolating transformers, supply isolators and signal converters for DC standard signals Temperature measuring transducers for resistance thermometers and thermocouples, frequency converters, potentiometer-measuring-transducers, bridge measuring transducers (strain gauges) trip amplifiers and modules for monitoring electrical and non-electrical process variables AD/DA converters displays calibration devices The products mentioned are available as pure signal converters / isolation transducers, 2-way/3-way isolators, supply isolators, passive isolators or as trip amplifiers. When used for industrial monitoring applications, sensors can record ambience conditions. Sensor signals are used within the process to continually track changes to the area being monitored. Both digital and analogue signals can occur. Normally an electrical voltage or current value is produced which corresponds proportionally to the physical variables that are being monitored Analogue signal processing is required when automation processes have to constantly maintain or reach defined conditions. This is particularly significant for process automation applications. Standardised electrical signals are typically used for process engineering. Analogue standardised currents / voltage 0(4)...20 mA/ 0...10 V have established themselves as physical measurement and control variables. Weidmüller meets the ever increasing challenges of automation and offers a product portfolio tailored to the requirements of handling sensor signals in analogue signal processing The analogue signal processing products can be used universally in combination with other Weidmüller products and in combination among each other. Their electrical and mechanical design is such that they require only minimal wiring efforts. Housing types and wire-connection methods matched to the respective application facilitate the universal use in process and industrial automation applications. The product line includes the following functions: Isolating transformers, supply isolators and signal converters for DC standard signals Temperature measuring transducers for resistance thermometers and thermocouples, frequency converters, potentiometer-measuring-transducers, bridge measuring transducers (strain gauges) trip amplifiers and modules for monitoring electrical and non-electrical process variables AD/DA converters displays calibration devices The products mentioned are available as pure signal converters / isolation transducers, 2-way/3-way isolators, supply isolators, passive isolators or as trip amplifiers.

Analogue signal processing When used for industrial monitoring applications, sensors can record ambience conditions. Sensor signals are used within the process to continually track changes to the area being monitored. Both digital and analogue signals can occur. Normally an electrical voltage or current value is produced which corresponds proportionally to the physical variables that are being monitored Analogue signal processing is required when automation processes have to constantly maintain or reach defined conditions. This is particularly significant for process automation applications. Standardised electrical signals are typically used for process engineering. Analogue standardised currents / voltage 0(4)...20 mA/ 0...10 V have established themselves as physical measurement and control variables. Weidmüller meets the ever increasing challenges of automation and offers a product portfolio tailored to the requirements of handling sensor signals in analogue signal processing The analogue signal processing products can be used universally in combination with other Weidmüller products and in combination among each other. Their electrical and mechanical design is such that they require only minimal wiring efforts. Housing types and wire-connection methods matched to the respective application facilitate the universal use in process and industrial automation applications. The product line includes the following functions: Isolating transformers, supply isolators and signal converters for DC standard signals Temperature measuring transducers for resistance thermometers and thermocouples, frequency converters, potentiometer-measuring-transducers, bridge measuring transducers (strain gauges) trip amplifiers and modules for monitoring electrical and non-electrical process variables AD/DA converters displays calibration devices The products mentioned are available as pure signal converters / isolation transducers, 2-way/3-way isolators, supply isolators, passive isolators or as trip amplifiers. When used for industrial monitoring applications, sensors can record ambience conditions. Sensor signals are used within the process to continually track changes to the area being monitored. Both digital and analogue signals can occur. Normally an electrical voltage or current value is produced which corresponds proportionally to the physical variables that are being monitored Analogue signal processing is required when automation processes have to constantly maintain or reach defined conditions. This is particularly significant for process automation applications. Standardised electrical signals are typically used for process engineering. Analogue standardised currents / voltage 0(4)...20 mA/ 0...10 V have established themselves as physical measurement and control variables. Weidmüller meets the ever increasing challenges of automation and offers a product portfolio tailored to the requirements of handling sensor signals in analogue signal processing The analogue signal processing products can be used universally in combination with other Weidmüller products and in combination among each other. Their electrical and mechanical design is such that they require only minimal wiring efforts. Housing types and wire-connection methods matched to the respective application facilitate the universal use in process and industrial automation applications. The product line includes the following functions: Isolating transformers, supply isolators and signal converters for DC standard signals Temperature measuring transducers for resistance thermometers and thermocouples, frequency converters, potentiometer-measuring-transducers, bridge measuring transducers (strain gauges) trip amplifiers and modules for monitoring electrical and non-electrical process variables AD/DA converters displays calibration devices The products mentioned are available as pure signal converters / isolation transducers, 2-way/3-way isolators, supply isolators, passive isolators or as trip amplifiers. When used for industrial monitoring applications, sensors can record ambience conditions. Sensor signals are used within the process to continually track changes to the area being monitored. Both digital and analogue signals can occur. Normally an electrical voltage or current value is produced which corresponds proportionally to the physical variables that are being monitored Analogue signal processing is required when automation processes have to constantly maintain or reach defined conditions. This is particularly significant for process automation applications. Standardised electrical signals are typically used for process engineering. Analogue standardised currents / voltage 0(4)...20 mA/ 0...10 V have established themselves as physical measurement and control variables. Weidmüller meets the ever increasing challenges of automation and offers a product portfolio tailored to the requirements of handling sensor signals in analogue signal processing The analogue signal processing products can be used universally in combination with other Weidmüller products and in combination among each other. Their electrical and mechanical design is such that they require only minimal wiring efforts. Housing types and wire-connection methods matched to the respective application facilitate the universal use in process and industrial automation applications. The product line includes the following functions: Isolating transformers, supply isolators and signal converters for DC standard signals Temperature measuring transducers for resistance thermometers and thermocouples, frequency converters, potentiometer-measuring-transducers, bridge measuring transducers (strain gauges) trip amplifiers and modules for monitoring electrical and non-electrical process variables AD/DA converters displays calibration devices The products mentioned are available as pure signal converters / isolation transducers, 2-way/3-way isolators, supply isolators, passive isolators or as trip amplifiers. -

Relay module Relays are available in different forms – from modular terminal enclosures to plug-in bases for terminal rail mounting. For switching and amplification of digital signals in automation engineering as well as for electrical isolation between control and load circuit. The input voltages (coil voltage) lie between 5 and 230 V AC/DC depending on type. Different types of contacts such as NOC, NCC and CO contacts are available at the output The use of different contact materials enables the switching of power ratings from just a few mW to max. 4 kVA. Industrial

Relay module Relays are available in different forms – from modular terminal enclosures to plug-in bases for terminal rail mounting. For switching and amplification of digital signals in automation engineering as well as for electrical isolation between control and load circuit. The input voltages (coil voltage) lie between 5 and 230 V AC/DC depending on type. Different types of contacts such as NOC, NCC and CO contacts are available at the output The use of different contact materials enables the switching of power ratings from just a few mW to max. 4 kVA. Industrial- Oil & Gas

- Chemical & Petrochemical

- Paper

- Steel

- Pulp & Paper

- Electronic

- Renewable Energy

- Transportation

-

Solid-state relays Solid-state relays are available in different forms – from modular terminal enclosures to plug-in bases for terminal rail mounting. For contactless switching and amplification of digital signals in automation engineering Based on a wide enclosure platform, Weidmüller has the optimum component for every application. Weidmüller solid-state relays are available with nominal voltages of 5 to 230 V on the input side. Optional DC and AC outputs enable the switching of loads in the most diverse applications. Industrial