-

Special Features & Benefits Enhanced reliability, Longer service life Tight sealing, Consistent low torque Assured shaft sealing One-piece blowout-proof Shaft Reliable Drive - Positive shaft-disc connection Lower resistance to flow - Contoured disc Ease of installation Integral actuator mounting platform

Special Features & Benefits Enhanced reliability, Longer service life Tight sealing, Consistent low torque Assured shaft sealing One-piece blowout-proof Shaft Reliable Drive - Positive shaft-disc connection Lower resistance to flow - Contoured disc Ease of installation Integral actuator mounting platform -

Aquaseal Max is a fabricated steel butterfly valve developed as an alternate for cast iron butterfly and sluice valves in water distribution systems. The highly reliable valve also finds application in power plants, utility and fire water lines, and HVAC systems. Customised Aquaseal Max can be used to handle air, gases and vacuum services. The valve has successfully under gone Proof of Design (POD) test as per AWWA C 504 and AWWA C 516. The key feature of Aquaseal Max Fabricated Steel Butterfly Valve is a Self-energising Disc Seal that uses line pressure to provide assured sealing. Special Features & Benefits Self-energising Disc Seal - Bi-directional bubble-tight sealing Assured Sealing to Atmosphere Lighter and Stronger Construction Lower Torque, Longer Life Maintenance-free Bearings

Aquaseal Max is a fabricated steel butterfly valve developed as an alternate for cast iron butterfly and sluice valves in water distribution systems. The highly reliable valve also finds application in power plants, utility and fire water lines, and HVAC systems. Customised Aquaseal Max can be used to handle air, gases and vacuum services. The valve has successfully under gone Proof of Design (POD) test as per AWWA C 504 and AWWA C 516. The key feature of Aquaseal Max Fabricated Steel Butterfly Valve is a Self-energising Disc Seal that uses line pressure to provide assured sealing. Special Features & Benefits Self-energising Disc Seal - Bi-directional bubble-tight sealing Assured Sealing to Atmosphere Lighter and Stronger Construction Lower Torque, Longer Life Maintenance-free Bearings -

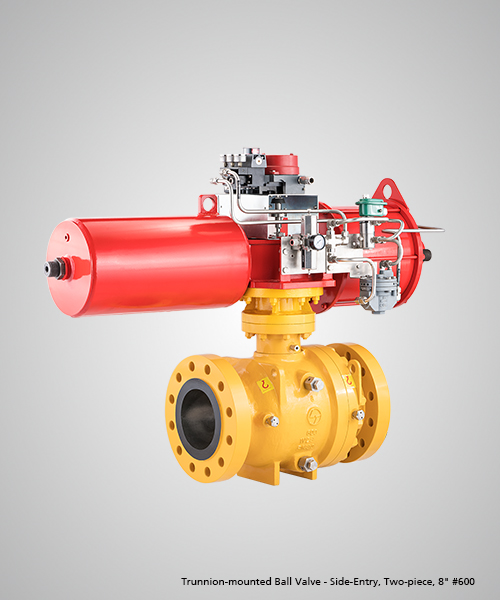

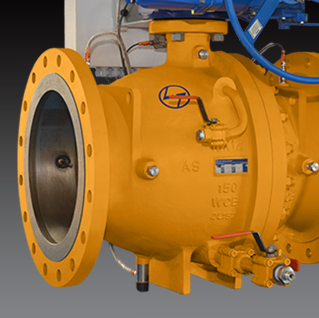

Special Features & Benefits Design complies to API 6D Valves offered with API 6D monogram Fugitive emissions – Complies to ISO 15848-1 Fire safety - Complies to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design examination certificate (certified by DNV) available Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL3 - Safety Integrity Level SIL3 certification complies to IEC 61508 L&T Valves Double Block & Bleed Plug Valve provides online-verifiable bubble tight sealing and is a safe and reliable replacement to the conventional two-valve system High integrity positive shut-off obtained independent of line pressure, without sealants/ lubricants Mechanical sealing ensuring online-verifiable positive double isolation for critical services Patented operator mechanism enables segments to move towards the seats during valve operation – reduces wear and tear and enhances service life Inbuilt cavity pressure relief system Inline Maintainable Seats -Seats can be renewed without removing the valve from the pipeline (after draining and isolating the line)

Special Features & Benefits Design complies to API 6D Valves offered with API 6D monogram Fugitive emissions – Complies to ISO 15848-1 Fire safety - Complies to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design examination certificate (certified by DNV) available Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL3 - Safety Integrity Level SIL3 certification complies to IEC 61508 L&T Valves Double Block & Bleed Plug Valve provides online-verifiable bubble tight sealing and is a safe and reliable replacement to the conventional two-valve system High integrity positive shut-off obtained independent of line pressure, without sealants/ lubricants Mechanical sealing ensuring online-verifiable positive double isolation for critical services Patented operator mechanism enables segments to move towards the seats during valve operation – reduces wear and tear and enhances service life Inbuilt cavity pressure relief system Inline Maintainable Seats -Seats can be renewed without removing the valve from the pipeline (after draining and isolating the line) -

Special Features & Benefits Taper Plug Design - Lower operating torque compared to lubricated plug valves Plug Adjustment Option - Enables on-line maintenance Avoids downtime Large PTFE Sleeve - Bubble-tight shutoff No metal-to-metal contact Longer service life Positively-locked Sleeve - Reliable sealing through thermal cycles Wiping action between sleeve and plug - Durability in slurry lines Reverse-lip PFA Diaphragm - Self-adjusting dynamic stem seal provides assured sealing to atmosphere Rugged Body - Long and reliable service life No Cavities - Line Fluid does not get entrapped

Special Features & Benefits Taper Plug Design - Lower operating torque compared to lubricated plug valves Plug Adjustment Option - Enables on-line maintenance Avoids downtime Large PTFE Sleeve - Bubble-tight shutoff No metal-to-metal contact Longer service life Positively-locked Sleeve - Reliable sealing through thermal cycles Wiping action between sleeve and plug - Durability in slurry lines Reverse-lip PFA Diaphragm - Self-adjusting dynamic stem seal provides assured sealing to atmosphere Rugged Body - Long and reliable service life No Cavities - Line Fluid does not get entrapped -

High Integrity Pressure Protection System L&T Valves offers a range of customised SIL3-capable High Integrity Pressure Protection Systems (HIPPS) for over-pressure protection In industrial plants, in case of over-pressurisation, the gases released are primarily flared. Flaring and venting of flammable gases pose health and safety hazards and constitute a significant threat to the environment.

High Integrity Pressure Protection System L&T Valves offers a range of customised SIL3-capable High Integrity Pressure Protection Systems (HIPPS) for over-pressure protection In industrial plants, in case of over-pressurisation, the gases released are primarily flared. Flaring and venting of flammable gases pose health and safety hazards and constitute a significant threat to the environment. -

Automation Solutions Leveraging flow-control expertise that spans five decades and in-house capabilities in system design and integration, L&T Valves offers a comprehensive range of SIL-capable Valve Automation Solutions to meet myriad industry/ process/ customer requirements. Special Features & Benefits Product Range: High Integrity Pressure Protection Systems (HIPPS) Emergency Shut Down Valves (ESDV) Shut Down Valves (SDV) Remote Operated Shutoff Valves (ROSOV) Blowdown Valves (BDV) On/ Off Valves Remote Operated Valves/ Motor-operated Valves

Automation Solutions Leveraging flow-control expertise that spans five decades and in-house capabilities in system design and integration, L&T Valves offers a comprehensive range of SIL-capable Valve Automation Solutions to meet myriad industry/ process/ customer requirements. Special Features & Benefits Product Range: High Integrity Pressure Protection Systems (HIPPS) Emergency Shut Down Valves (ESDV) Shut Down Valves (SDV) Remote Operated Shutoff Valves (ROSOV) Blowdown Valves (BDV) On/ Off Valves Remote Operated Valves/ Motor-operated Valves -

Features L&T Valves launches a smart flow-control solution that enhances plant safety and reliability - L&T Valves Asset Management Program, LAMP. This IoT-ready remote valve performance monitoring system leverages expertise in valve manufacture as well as system design and integration. At the core of LAMP is a time-tested SIL3-capable valve - Ball, Butterfly, DBB Plug, Gate or Globe. Each valve is equipped with ValvTrac™ digital traceability tag that cross-links valve signature to traceability information such as valve test certificates, material test certificates, and installation, operation and maintenance manuals. The valves are upgraded to ‘Smart Valves’ by integrating them with next-generation smart sensors that measure parameters such as torque, leakage, vibration, pressure, temperature and position. The data is relayed real-time to a secure, dedicated cloud computing platform where it is analyzed to provide complete valve health and diagnostic information. Valve users can access information through a secure login, or port the data to the native asset management system through any standard field communication protocol (HART, WirelessHART, Foundation Fieldbus, etc.). To a customer, knowledge is trust; the more he knows about the state of a valve, the more confident can he be about its performance. Thus LAMP takes the guesswork out of valve maintenance and allows customers to transition from preventive maintenance based on thumb rules to predictive maintenance based on real data.

Features L&T Valves launches a smart flow-control solution that enhances plant safety and reliability - L&T Valves Asset Management Program, LAMP. This IoT-ready remote valve performance monitoring system leverages expertise in valve manufacture as well as system design and integration. At the core of LAMP is a time-tested SIL3-capable valve - Ball, Butterfly, DBB Plug, Gate or Globe. Each valve is equipped with ValvTrac™ digital traceability tag that cross-links valve signature to traceability information such as valve test certificates, material test certificates, and installation, operation and maintenance manuals. The valves are upgraded to ‘Smart Valves’ by integrating them with next-generation smart sensors that measure parameters such as torque, leakage, vibration, pressure, temperature and position. The data is relayed real-time to a secure, dedicated cloud computing platform where it is analyzed to provide complete valve health and diagnostic information. Valve users can access information through a secure login, or port the data to the native asset management system through any standard field communication protocol (HART, WirelessHART, Foundation Fieldbus, etc.). To a customer, knowledge is trust; the more he knows about the state of a valve, the more confident can he be about its performance. Thus LAMP takes the guesswork out of valve maintenance and allows customers to transition from preventive maintenance based on thumb rules to predictive maintenance based on real data. -

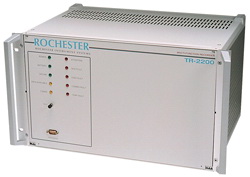

Application • For all types of power system events • Simultaneously perform: transient recording, disturbance recording, phasor measurements, power quality analysis, and sequence of events recording. • The system can operate automatically to retrieve events and perform an expert analysis so you have the answers fast, saving time and money. • Providing all the answers in one software platform. • The TR-2000 is ideally suited for your generation, transmission, and distribution power system monitoring.

Application • For all types of power system events • Simultaneously perform: transient recording, disturbance recording, phasor measurements, power quality analysis, and sequence of events recording. • The system can operate automatically to retrieve events and perform an expert analysis so you have the answers fast, saving time and money. • Providing all the answers in one software platform. • The TR-2000 is ideally suited for your generation, transmission, and distribution power system monitoring. -

Application

Application- Fault and Disturbance Recorder

- Transient Fault Location

- Phasor Measurement Unit

- Power Quality Monitor

- Sequence of Events Recorder

- Built in DSP for computations

- 16 bits, 32768 levels (15 plus sign)

- Fixed 512 samples/cycle (26KHz/31KHz)

- Accuracy better than 0.1% of reading down to 3% of full scale Voltage Input Ranges

- 1.414, 10, 150, 300V RMS full-scale or custom range (AC or DC compatible) Current Input Ranges

- 1 A or 5 A RMS nominal (thru current shunts/CICT’s) Frequency Response

- DC-1/2 sampling rate Digital Inputs

- 24 to 250 VDC normally open or closed wetted contact Input Module

- 6 analog (current or voltage) and 12 digital Inputs System Capacity (1-6 Input Modules)

- 6, 12, 18, 24, 30 or 36 analog

- 12, 24, 36, 48, 60 or 72 digital (multiple units tied together for larger systems)

- 1 usec. or better

- Internal GPS receiver

- IRIG-B (Mod & TTL)

- Network Time Protocol (NTP)

- 4U (7”) 19” chassis mount

-

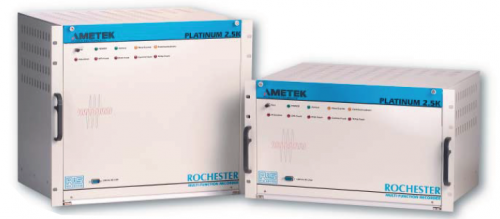

Application

Application- The Platinum 2.5K Portable Multi-Function Recorder is packaged in a rugged case with quick connect interfaces for fast and simple field connection.

- Interface cables are provided with shrouded banana jacks that couple easily with a variety of measurement CT’s and voltage scaling devices offering complete flexibility for power utility and industrial use.

- High-speed sinusoid data for traditional fault recorder analysis

- Slower speed data for disturbance or swing recording

- Continuous logging of RMS and phasor data for disturbance monitoring

- Steady-state logging of RMS and harmonic spectrum values

- System frequency for power quality analysis

- 8 analog and 16 digital Voltage Inputs

- 63.5 or 110 V RMS nominal

- 480 or 600V RMS nominal (via external box) Current Inputs

- 1 A or 5 A RMS nominal (thru current transformers, other ranges available) Frequency Response

- DC – 1/2 sampling rate (1/4 sampling rate for 384 samples per cycle only) Accuracy

- Better than 0.1% of full scale Digital Inputs

- 24/48/125/250 VDC normally open or closed wetted contact

- Optional internal GPS receiver with 1 PPS output for phasor measurement Accuracy

- Normally better than +/- 60 ns

- 30 lbs. (DIM)

-

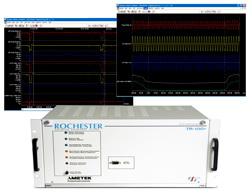

Application The AMETEK TR-100+ is a fully featured Digital Fault Recorder with the capability to capture and analyze short transient events, longer-term disturbances and trend input quantities such as RMS, frequency, harmonics, power and power factor. Specifications INPUTS Number of Channels • 8, 16, 24, or 32 analog

Application The AMETEK TR-100+ is a fully featured Digital Fault Recorder with the capability to capture and analyze short transient events, longer-term disturbances and trend input quantities such as RMS, frequency, harmonics, power and power factor. Specifications INPUTS Number of Channels • 8, 16, 24, or 32 analog- 16, 32, 48, or 64 digital (larger systems available) Voltage Inputs

- 57 to120 V RMS nominal, 212 V RMS full scale Current Inputs

- 1 A or 5 A RMS nominal (thru external current shunts/CICT’s) Frequency Response • DC to 3,000 Hz, (+0dB, -3dB) or 1/4 sample rate Accuracy

- Better than 0.2% full scale Digital Inputs • 24-250 VDC normally open or normally closed wetted contact

- Internal clock, synched to the 50/60 Hz line or optional IRIG-B

-

Application

Application- The Platinum 2.5K Portable Multi-Function Recorder is packaged in a rugged case with quick connect interfaces for fast and simple field connection.

- Interface cables are provided with shrouded banana jacks that couple easily with a variety of measurement CT’s and voltage scaling devices offering complete flexibility for power utility and industrial use.

- High-speed sinusoid data for traditional fault recorder analysis

- Slower speed data for disturbance or swing recording

- Continuous logging of RMS and phasor data for disturbance monitoring

- Steady-state logging of RMS and harmonic spectrum values

- System frequency for power quality analysis

- Number of Channels 8 analog and 16 digital Voltage Inputs

- 63.5 or 110 V RMS nominal

- 480 or 600V RMS nominal (via external box) Current Inputs

- 1 A or 5 A RMS nominal (thru current transformers, other ranges available) Frequency Response

- DC – 1/2 sampling rate (1/4 sampling rate for 384 samples per cycle only) Accuracy

- Better than 0.1% of full scale Digital Inputs

- 24/48/125/250 VDC normally open or closed wetted contact

- Optional internal GPS receiver with 1 PPS output for phasor measurement Accuracy

- Normally better than +/- 60 ns

- 30 lbs. (DIM)

-

Application The Fault Recorder product family is enhanced with our full suite of software applications designed to simplify the process of configuring our recorders, retrieving event information, and analyzing the results. Tools like our automated event retrieval and expert analysis provide the quickest results when classifying an abnormal event. Detailed fault analysis is easily accomplished with our set of power analysis tools and flexible display options.

Application The Fault Recorder product family is enhanced with our full suite of software applications designed to simplify the process of configuring our recorders, retrieving event information, and analyzing the results. Tools like our automated event retrieval and expert analysis provide the quickest results when classifying an abnormal event. Detailed fault analysis is easily accomplished with our set of power analysis tools and flexible display options. -

Application

Application- Power quality monitor--measures voltage and frequency profiles, voltage dips and surges, loss or supply, harmonic content, flicker, voltage and current imbalance

- Transient fault recorder--analog inputs are sampled at up to 128 samples per cycle with a maximum record length of 2 seconds

- Disturbance Recorder/Logger--analog inputs are sampled at up to 2 samples per cycle with RMS measurements recorded up to one minute

- Trend Recording--input and computed quantities are logged as maximum, minimum and average quantities every minute for up to 16 weeks.

- Remote Capabilities-via Ethernet or modem, and the process can be automated using the record's Auto-Call or Auto-Poll features.

- Software--wide range of application software for communicating, configuring, downloading, displaying and analyzing recorded data. Auto-poll/Call automates the complete process of retrieving your recorded data.

- 8 (4 voltage, 4 current) consult factory for other configurations Voltage Inputs

- 150/300/600 RMS maximum, Star (wye) or delta connections Current Inputs

- 1/5/100/200/500/1000 A RMS nominal thru external CTs. designed to record to 40% over-range Frequency Response

- 40Hz-3kHz. (+0dB, -3dB for voltages) DC-3kHz (+0dB for currents) Accuracy

- Better than 0.2% of full scale

- 32,768 Hz internal crystal oscillator

- 1 ms

- Time and date (including leap year and day of the year) Synchronization

- 50/60 Hz from voltage input

- Wall (internal terminals) — 11.75 in. x 16.0 in. x 8.25 in. (300 mm x 400 mm x 210 mm)

- 19" Rack Mounting — 13.25 in. x 19.0 in. x 5.25 in. (336 mm x 482 mm x 133 mm)

- Portable — 14.25 in. x 13.75 in. x 5.25 in. (362 mm x 349 mm x 133 mm) Weight

- 13.2-17.6 lbs. (6-8 kg) depending on enclosure style

-

Application

Application- AMETEK’s JEMStar II has the highest accuracy in the market.

- Provides many communication options and monitors your power quality to make it the ideal choice for any metering application.

- An impressive color display makes it easy to view power measurements, phasor displays and meter diagnostics.

- The JEMStar II is easy to use and configure with our intuitive JEMWARE software and the meter display provides a user menu to show and edit configuration details.

- The JEMStar II has a GB of non-volatile memory to store your metering and power quality data for as long as you want.

- The meter has a single base model that can be used for simple revenue and billing applications as well as more complex power quality monitoring applications.

- Meter Forms: 5, 6, 8, 9, 45, Universal

- 55-300 VAC auto-ranging

- Burden*: 0.5 VA @ 300V * Does not include auxiliary power requirements.

- 1 amp: ANSI class 2

- 5 amps: ANSI class 10

- 10 amps: ANSI class 20

- Burden: 0.5 VA maximum

- Overload: 1.5x rated class current continuous

- Starting current: 0.002 A

- Frequency range: 45-55 Hz, 55-65 Hz

- Aux Power: 55-300 VAC or 90-300 VDC Auxiliary Power Burden

- 25 VA maximum

- 0.05% reading (0.02% typical) Volts, Amps

- 0.04% reading

- 16 channels storage

- 1-60 minute intervals

- Internal clock: 0.5 sec/day accuracy

- 50/60HZ line frequency

- External time sync options: NTP

-

Application

Application- AMETEK’s JEMStar II has the highest accuracy in the market.

- Provides many communication options and monitors your power quality to make it the ideal choice for any metering application.

- An impressive color display makes it easy to view power measurements, phasor displays and meter diagnostics.

- The JEMStar II is easy to use and configure with our intuitive JEMWARE software and the meter display provides a user menu to show and edit configuration details.

- The JEMStar II has a GB of non-volatile memory to store your metering and power quality data for as long as you want.

- The meter has a single base model that can be used for simple revenue and billing applications as well as more complex power quality monitoring applications.

- Meter Forms: 5, 6, 8, 9, 45, Universal

- 55-530 VAC auto-ranging

- Burden*: 0.5 VA @ 530V * Does not include auxiliary power requirements.

- 1 amp: ANSI class 2

- 5 amps: ANSI class 10

- 10 amps: ANSI class 20

- Burden: 0.5 VA maximum

- Overload: 1.5x rated class current continuous

- Starting current: 0.002 A

- Frequency range: 45-55 Hz, 55-65 Hz

- Self powered via all three phases: 55-530 VAC

- External Aux Power Option: 55-530 VAC or 90-300 VDC; 19-58 VDC

- Aux Power: 55-530 VAC or 90-300 VDC; 19-58 VDC option

- 25 VA maximum

- 0.05% reading (0.02% typical) Volts, Amps

- 0.04% reading

- 16 channels storage

- 1-60 minute intervals

- Internal clock: 0.5 sec/day accuracy

- 50/60HZ line frequency

- External time sync options: IRIG-B, NTP, IEEE-1588, PPS

-

Application

Application- AMETEK’s Ci20 Revenue Meter watches over your energy investment in many ways.

- It has high accuracy measurements, site diagnostics and dependable communication options to ensure maximum reliability

- Your installation investment is reduced with our innovative software wizard that provides quick set-up and configuration.

- Inventory and ordering is simplified with field upgradeable options using soft switches and plug in boards.

- 55-530 VAC auto-ranging

- Burden*: 0.5 VA @ 530V *Does not include auxiliary power requirements.

- 10 Amps: ANSI Class 20

- Burden: 0.5 VA maximum

- Overload: 1.5x rated class current continuous, 20x rated class current for 0.50 sec

- Frequency range: 45-55 Hz, 55-65 Hz

- Derived from from A,B or C phase voltage input Auxiliary Power Burden

- 15 VA maximum

- 0.15% reading Clock

- Synchronized to line

- 4 Channels of Storage (Standard) Programmable Interval

- 1-60 minutes 64 Days Storage Using Four Channels at 15-minute Intervals

-

Features Based on Tunable Diode Laser Absorption Spectroscopy (TDLAS) The 5100P analyzer provides simple, easy-to-use moisture analysis using tunable diode laser absorption spectroscopy (TDLAS) in a durable, lightweight, and mobile package for measurements in natural gas. Designed to be intuitive to start-up and log data, the 5100P is the tool-of-choice for users needing to perform measurements in remote locations or verify fixed analyzer installations.

Features Based on Tunable Diode Laser Absorption Spectroscopy (TDLAS) The 5100P analyzer provides simple, easy-to-use moisture analysis using tunable diode laser absorption spectroscopy (TDLAS) in a durable, lightweight, and mobile package for measurements in natural gas. Designed to be intuitive to start-up and log data, the 5100P is the tool-of-choice for users needing to perform measurements in remote locations or verify fixed analyzer installations.- Fast response, highly accurate measurements

- Integrated sample system removes contaminants

- Rechargeable battery for at least 8 hours of operation

- Lightweight package simplifies transporting the device between locations

- Certified for use in hazardous areas

- Minimal maintenance required

- Measurement confidence

- Increased efficiency

- Oil & Gas

- Chemical & Petrochemical

-

Features ACCURATE DETERMINATION OF THE DEW POINT OF NATURAL GAS The Chanscope IITM was designed to meet the need for a user friendly dew point tester. It measures the dew point of the sample gas through the use of a chilled mirror as required by ASTM D1142. This device bears a number of significant improvements to usability over the standard dew point tester:

Features ACCURATE DETERMINATION OF THE DEW POINT OF NATURAL GAS The Chanscope IITM was designed to meet the need for a user friendly dew point tester. It measures the dew point of the sample gas through the use of a chilled mirror as required by ASTM D1142. This device bears a number of significant improvements to usability over the standard dew point tester:- The mirror is illuminated making it much easier to see dew formation and identify the type of dew on the mirror

- The temperature of the mirror is displayed above the mirror itself electronically thereby making it much easier to identify the exact temperature at which the dew forms.

- The temperature sensor operates over the full range of possible dew points thereby eliminating the need to have multiple testers of varying dew point range

- Oil & Gas

- Chemical & Petrochemical

-

Features The 303B offers highly accurate portable measurement of trace moisture in gas streams for division 2 areas. Using an electrolytic (P2O5) sensor, the 303B can be used to monitor nearly all gases. It is compact, lightweight, and suitable for both portable use and permanent installation in Class I Div. 2 areas. With the optional carrying bag and lightweight design, the 303B is truly portable. APPLICATIONS : The 303B is designed to measure moisture content in gases such as air, nitrogen, argon, natural gas, and others with comparable characteristics. Typical applications are:

Features The 303B offers highly accurate portable measurement of trace moisture in gas streams for division 2 areas. Using an electrolytic (P2O5) sensor, the 303B can be used to monitor nearly all gases. It is compact, lightweight, and suitable for both portable use and permanent installation in Class I Div. 2 areas. With the optional carrying bag and lightweight design, the 303B is truly portable. APPLICATIONS : The 303B is designed to measure moisture content in gases such as air, nitrogen, argon, natural gas, and others with comparable characteristics. Typical applications are:- Monitoring natural gas pipelines and gas treatment processes

- Monitoring air humidity in dry boxes

- Continuous monitoring of atmospheres in simulated space chambers

- Sensing elements in humidity control systems

- Monitoring inert protective atmospheres in brazing or sintering furnaces

- Monitoring moisture in many fluorocarbon gases

- Constant measurement of batch and continuous driers to assure quality control without the expense of overdrying

- Monitoring anhydrous batch chemical processes at startup

- Quality control of transistor and diode backfill gas

- Instrument air systems

- Cryogenic processes

- Radar waveguides

- Oil & Gas

- Chemical & Petrochemical

-

Features The Ranarex Portable Gas Gravitometer is an easy-to-use, fast responding gas gravitometer that is used to determine the specific gravity of a process gas as compared with air. This unit offers multiple scales and field-proven accuracy within 0.05% of actual value at any reading. Dual ranges are available: 0.52-1.03 and 0.097-1.90 relative density (specific gravity). Plant and process operators need a reliable, simple means of confirming the quality or mixture of process gases. The means used to perform these tests must be reliable, accurate, and very affordable. For many processes and situations, gas quality can be easily inferred through a simple analysis of the gas mixture's specific gravity as opposed to a complex spectral analysis. Industrial

Features The Ranarex Portable Gas Gravitometer is an easy-to-use, fast responding gas gravitometer that is used to determine the specific gravity of a process gas as compared with air. This unit offers multiple scales and field-proven accuracy within 0.05% of actual value at any reading. Dual ranges are available: 0.52-1.03 and 0.097-1.90 relative density (specific gravity). Plant and process operators need a reliable, simple means of confirming the quality or mixture of process gases. The means used to perform these tests must be reliable, accurate, and very affordable. For many processes and situations, gas quality can be easily inferred through a simple analysis of the gas mixture's specific gravity as opposed to a complex spectral analysis. Industrial- Oil & Gas

- Chemical & Petrochemical

-

Features Natural gas pipeline operations are dramatically impacted by the presence or formation of liquids within the gas pipeline. The dew point of the natural gas must be periodically checked in order to ensure that troublesome liquid formation is not occuring in the pipeline. Operators and technicians need an accurate, rugged means of determining the dew point of the gas within the pipeline. This device is completely manual. The observor is not only the 'detector', they must also manually control the rate of mirror cooling and read the indicated temperature at the appropriate time. When used by a skilled operator, this device will produce extremely accurate dew point measurements. The Standard Dew Point Tester, is available in a variety of dew point temperature and pressure ranges. The Solution This industry need was met with the development of the Standard Dew Point Tester. The device works as follows: The sample gas to be analyzed is slowly passed, at pipeline pressure, over a mirror. The mirror is slowly cooled through the use of a manually regulated refrigerant gas. A thermometer accurately reads the temperature of the mirror while an operator observes the mirror for the formation of dew. When dew is observed, the dew point temperature is read off the thermometer. The type of dew formed on the mirror can be determined by an experienced user. Use of this device is described by ASTM D1142. Industrial

Features Natural gas pipeline operations are dramatically impacted by the presence or formation of liquids within the gas pipeline. The dew point of the natural gas must be periodically checked in order to ensure that troublesome liquid formation is not occuring in the pipeline. Operators and technicians need an accurate, rugged means of determining the dew point of the gas within the pipeline. This device is completely manual. The observor is not only the 'detector', they must also manually control the rate of mirror cooling and read the indicated temperature at the appropriate time. When used by a skilled operator, this device will produce extremely accurate dew point measurements. The Standard Dew Point Tester, is available in a variety of dew point temperature and pressure ranges. The Solution This industry need was met with the development of the Standard Dew Point Tester. The device works as follows: The sample gas to be analyzed is slowly passed, at pipeline pressure, over a mirror. The mirror is slowly cooled through the use of a manually regulated refrigerant gas. A thermometer accurately reads the temperature of the mirror while an operator observes the mirror for the formation of dew. When dew is observed, the dew point temperature is read off the thermometer. The type of dew formed on the mirror can be determined by an experienced user. Use of this device is described by ASTM D1142. Industrial- Oil & Gas

- Chemical & Petrochemical

-

Features The 3050 Moisture Analyzer series measures trace levels of moisture in a gas through the use of a quartz-crystal oscillator sample cell. AMETEK is the leader in quartz-crystal technology, which for thirty years has offered significant advantages over other measurement techniques: • Most accurate trace moisture measurement technology available • Responds far faster to both increasing and decreasing moisture levels • Specific to moisture in most applications • Provides a much more rugged sensor Because of these advantages, the quartz-crystal oscillator has become the industry standard for applications ranging from ultrahigh purity semiconductor gases to natural gas streams containing 30% H2S. Now, the 3050 analyzers bring the benefits of quartz-crystal technology to a broad spectrum of moisture applications. AME Vision Display Unit AMEVision allows users to continually monitor the measurement and diagnostic information from up to eight 3050 series moisture analyzers. AMEVision provides real-time moisture measurements, trend data, and details a variety of maintenance and troubleshooting information from the 3050. Users can communicate with AMEVision via Modbus RS485 and Ethernet LAN. • Compatible with 3050 models OLV, SLR, DO, and TE • Connect up to eight analyzers on one unit • Trend history • Automatic data capture and logging • Calibration history • Alarm history Industrial

Features The 3050 Moisture Analyzer series measures trace levels of moisture in a gas through the use of a quartz-crystal oscillator sample cell. AMETEK is the leader in quartz-crystal technology, which for thirty years has offered significant advantages over other measurement techniques: • Most accurate trace moisture measurement technology available • Responds far faster to both increasing and decreasing moisture levels • Specific to moisture in most applications • Provides a much more rugged sensor Because of these advantages, the quartz-crystal oscillator has become the industry standard for applications ranging from ultrahigh purity semiconductor gases to natural gas streams containing 30% H2S. Now, the 3050 analyzers bring the benefits of quartz-crystal technology to a broad spectrum of moisture applications. AME Vision Display Unit AMEVision allows users to continually monitor the measurement and diagnostic information from up to eight 3050 series moisture analyzers. AMEVision provides real-time moisture measurements, trend data, and details a variety of maintenance and troubleshooting information from the 3050. Users can communicate with AMEVision via Modbus RS485 and Ethernet LAN. • Compatible with 3050 models OLV, SLR, DO, and TE • Connect up to eight analyzers on one unit • Trend history • Automatic data capture and logging • Calibration history • Alarm history Industrial- Oil & Gas

- Chemical & Petrochemical

-

Features The versatile AMETEK 5000 is a highly sensitive moisture analyzer for process applications where the continuous, reliable measurement of moisture in vapors and gases is required. The 5000 analyzer measures moisture on-line by monitoring the vibrational frequency change of a hygroscopically sensitized quartz crystal that is exposed alternately to wet sample and dry reference gas for 30 second periods. The reference gas is sample gas passed through a molecular sieve dryer to remove virtually all its moisture content. TYPICAL APPLICATIONS

Features The versatile AMETEK 5000 is a highly sensitive moisture analyzer for process applications where the continuous, reliable measurement of moisture in vapors and gases is required. The 5000 analyzer measures moisture on-line by monitoring the vibrational frequency change of a hygroscopically sensitized quartz crystal that is exposed alternately to wet sample and dry reference gas for 30 second periods. The reference gas is sample gas passed through a molecular sieve dryer to remove virtually all its moisture content. TYPICAL APPLICATIONS- Catalytic Reforming

- Moisture in Olefins

- Moisture in Natural Gas

- Petroleum Refining - reforming; alkylation; LPG; light hydrocarbons; isomerization

- Natural Gas - cryogenic extraction; transmission stations; storage/distribution; LNG; production

- Petrochemicals - cracked gas; propylene; butadiene; ethylene

- Chemicals - fluorocarbon gases; vinyl chloride; vinyl fluoride; refrigerants; reactor gas blankets; methyl chloride

- Enhanced Oil Recovery - CO2 pipelines

- Electronics - doping gases; dielectric gases; soldering furnace atmospheres; brazing furnace atmospheres; blanketing gases

- Metals - annealing furnace atmospheres

- Oil & Gas

- Chemical & Petrochemical

-

Features 5100 Based on Tunable Diode Laser Absorption Spectroscopy (TDLAS) The 5100 hosts a single laser platform to measure a single gas analyte. The device can measure any one of the following gas analytes: water vapor, methane, hydrogen sulfide, carbon dioxide, and oxygen in process or flue gas. If water vapor is the measured gas analyte, methane can be monitored additionally at percent levels using the same laser. A key feature of the 5100 is the use of a sealed reference cell, which contains a known amount of analyte gas measured, for referencing the emission wavelength of the laser. The use of a reference cell enables both the ability to line-lock the lasers and to continuously verify the instrument calibration. The 5100 is designed to handle sample gases with dew points as high as 55ºC. For higher temperature dew point applications the 5100HD is recommended.

Features 5100 Based on Tunable Diode Laser Absorption Spectroscopy (TDLAS) The 5100 hosts a single laser platform to measure a single gas analyte. The device can measure any one of the following gas analytes: water vapor, methane, hydrogen sulfide, carbon dioxide, and oxygen in process or flue gas. If water vapor is the measured gas analyte, methane can be monitored additionally at percent levels using the same laser. A key feature of the 5100 is the use of a sealed reference cell, which contains a known amount of analyte gas measured, for referencing the emission wavelength of the laser. The use of a reference cell enables both the ability to line-lock the lasers and to continuously verify the instrument calibration. The 5100 is designed to handle sample gases with dew points as high as 55ºC. For higher temperature dew point applications the 5100HD is recommended.- All digital signal processing

- Web-based interface

- Connectivity by modbus, ethernet and analog

- Real-time performance monitoring

- Fully integrated sample handling

- Resistant to contamination

- Reference Cell enables Line Lock and Span Verification The 5100 offers high specificity, selectivity, speed of response and great reliability

- Oil & Gas

- Chemical & Petrochemical

-

Features 5100HD Based on Tunable Diode Laser Absorption Spectroscopy (TDLAS) The 5100HD hosts a dual laser platform. Two separate lasers are installed in the instrument, sharing a common optical path through the sample, enabling the measurement of two analytes simultaneously. This results in significant cost savings to our customers. Where the required concentrations of the analytes differ considerably such that different path lengths are required, two sample cells are used. The 5100HD is also capable of dual stream analysis, and can measure any two combinations of water vapor, methane, hydrogen sulfide, carbon dioxide, and oxygen in process or flue gas. Designed to handle sample gases with high dew points, the 5100HD standard version has its sample cell heated to a maximum of 100°C. A version is also available for 150°C. A key feature of this analyzer is the use of sealed reference cells, which contain known amounts of analyte gases measured, for referencing the emission wavelengths of the lasers. The use of reference cells enables both the ability to line-lock the lasers and to continuously verify the optical system performance. Industrial

Features 5100HD Based on Tunable Diode Laser Absorption Spectroscopy (TDLAS) The 5100HD hosts a dual laser platform. Two separate lasers are installed in the instrument, sharing a common optical path through the sample, enabling the measurement of two analytes simultaneously. This results in significant cost savings to our customers. Where the required concentrations of the analytes differ considerably such that different path lengths are required, two sample cells are used. The 5100HD is also capable of dual stream analysis, and can measure any two combinations of water vapor, methane, hydrogen sulfide, carbon dioxide, and oxygen in process or flue gas. Designed to handle sample gases with high dew points, the 5100HD standard version has its sample cell heated to a maximum of 100°C. A version is also available for 150°C. A key feature of this analyzer is the use of sealed reference cells, which contain known amounts of analyte gases measured, for referencing the emission wavelengths of the lasers. The use of reference cells enables both the ability to line-lock the lasers and to continuously verify the optical system performance. Industrial- Oil & Gas

- Chemical & Petrochemical

-

Features The 241CE II Hydrocarbon Dew Point Analyzer is a quality control tool for natural gas processing, distribution and consumption. Detection and measurement of hydrocarbon dewpoint is achieved in a single cell, single cycle operation. The dew point analyzer uses patented chilled-mirror technology. With the 241CE II Hydrocarbon Dew Point Analyzer, all monitoring and measuring of dew points is done automatically under control of an onboard computer, rather than by an operator. The dew point analyzer was designed for unattended operation. Accurate and objective direct measurement of hydrocarbon dew point temperature at pipeline pressure or Cricondentherm

Features The 241CE II Hydrocarbon Dew Point Analyzer is a quality control tool for natural gas processing, distribution and consumption. Detection and measurement of hydrocarbon dewpoint is achieved in a single cell, single cycle operation. The dew point analyzer uses patented chilled-mirror technology. With the 241CE II Hydrocarbon Dew Point Analyzer, all monitoring and measuring of dew points is done automatically under control of an onboard computer, rather than by an operator. The dew point analyzer was designed for unattended operation. Accurate and objective direct measurement of hydrocarbon dew point temperature at pipeline pressure or Cricondentherm- Proprietary three-stage filter provides superior protection

- Designed for unattended operation with low maintenance

- Compact design allows mounting in optional enclosures

- Digital communications vis Modbus RTU protocol

- Fully integrated sample system

- Hydrocarbon dew point temperature current output

- Oil & Gas

- Chemical & Petrochemical

-

Features AMETEK’s 2850 Moisture Analyzer establishes a new standard in clean gas moisture analyzers: ultrafast response speed, exceptional accuracy, virtually no interferences, multigas compatibility, and on-board measurement verification. This unique combination of capabilities makes the 2850 the moisture analyzer of choice for monitoring process desiccant dryers, instrument air dryers, or air separators, and for industrial gas production and quality assurance. Typical Applications

Features AMETEK’s 2850 Moisture Analyzer establishes a new standard in clean gas moisture analyzers: ultrafast response speed, exceptional accuracy, virtually no interferences, multigas compatibility, and on-board measurement verification. This unique combination of capabilities makes the 2850 the moisture analyzer of choice for monitoring process desiccant dryers, instrument air dryers, or air separators, and for industrial gas production and quality assurance. Typical Applications- Industrial gas production and quality assurance

- Cryogenic air separation

- Process dryers

- Oil & Gas

- Chemical & Petrochemical

-

Features The 3050 Moisture Analyzer series measures trace levels of moisture in a gas through the use of a quartz-crystal oscillator sample cell. AMETEK is the leader in quartz-crystal technology, which for thirty years has offered significant advantages over other measurement techniques:

Features The 3050 Moisture Analyzer series measures trace levels of moisture in a gas through the use of a quartz-crystal oscillator sample cell. AMETEK is the leader in quartz-crystal technology, which for thirty years has offered significant advantages over other measurement techniques:- Most accurate trace moisture measurement technology available

- Responds far faster to both increasing and decreasing moisture levels

- Specific to moisture in most applications

- Provides a much more rugged sensor Because of these advantages, the quartz-crystal oscillator has become the industry standard for applications ranging from ultrahigh purity semiconductor gases to natural gas streams containing 30% H2S. Now, the 3050 analyzers bring the benefits of quartz-crystal technology to a broad spectrum of moisture applications. AME Vision Display Unit AMEVision allows users to continually monitor the measurement and diagnostic information from up to eight 3050 series moisture analyzers. AMEVision provides real-time moisture measurements, trend data, and details a variety of maintenance and troubleshooting information from the 3050. Users can communicate with AMEVision via Modbus RS485 and Ethernet LAN.

- Compatible with 3050 models OLV, SLR, DO, and TE

- Connect up to eight analyzers on one unit

- Trend history

- Automatic data capture and logging

- Calibration history

- Alarm history

- Oil & Gas

- Chemical & Petrochemical