-

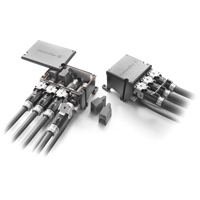

Weidmüller's BasicLine consists of unmanaged Plug & Play switches in a robust IP 30 protected aluminium housing. The equipment can be delivered with Fast Ethernet and Gigabit Ethernet ports and offers an economical solution for industrial Ethernet networks. One variety is fitted with Fast Ethernet and Power-over-Ethernet ports. All the equipment has been developed for use in harsh industrial environments and has international approvals such as CE, cULus, Class I Div. 2 / ATEX and DNV / GL, and is therefore able to be used in many international applications. Plug & Play switches in a rugged aluminium housing (IP 30) Compact design Switches for an economical entry solution Fast Ethernet versions with 5 and 8 ports Models with copper or fibre-optic interface (multimode and singlemode) Full Gigabit Plug and Play switch with 5 ports Power-over-Ethernet (PoE) switch with 6 Fast Ethernet ports, 4 of them PoE+ ports Approvals: CE, FCC, cULus, Class I Div. 2 / ATEX, DNV / GL

Weidmüller's BasicLine consists of unmanaged Plug & Play switches in a robust IP 30 protected aluminium housing. The equipment can be delivered with Fast Ethernet and Gigabit Ethernet ports and offers an economical solution for industrial Ethernet networks. One variety is fitted with Fast Ethernet and Power-over-Ethernet ports. All the equipment has been developed for use in harsh industrial environments and has international approvals such as CE, cULus, Class I Div. 2 / ATEX and DNV / GL, and is therefore able to be used in many international applications. Plug & Play switches in a rugged aluminium housing (IP 30) Compact design Switches for an economical entry solution Fast Ethernet versions with 5 and 8 ports Models with copper or fibre-optic interface (multimode and singlemode) Full Gigabit Plug and Play switch with 5 ports Power-over-Ethernet (PoE) switch with 6 Fast Ethernet ports, 4 of them PoE+ ports Approvals: CE, FCC, cULus, Class I Div. 2 / ATEX, DNV / GL -

Identification systems Weidmüller offers a comprehensive range of products for marking devices, conductors and connectors. The marking systems import data from your existing CAE software for fast and permanent printing. The MultiCard concept from Weidmüller has now become established as a worldwide standard. High-quality, trendsetting marking systems are available for both Weidmüller products and competing products. These range from laser, thermal transfer and ink-jet printers for diverse applications up to plotters and ensure clear and permanent labelling. On request, Weidmüller also supplies ready-printed markers. An extensive range of materials, e.g. labels, shrink sleeves, cable ties, junction box terminals with the tried-and-tested tension clamp connections as well as lighting terminals for effective wiring is also available. Industrial

Identification systems Weidmüller offers a comprehensive range of products for marking devices, conductors and connectors. The marking systems import data from your existing CAE software for fast and permanent printing. The MultiCard concept from Weidmüller has now become established as a worldwide standard. High-quality, trendsetting marking systems are available for both Weidmüller products and competing products. These range from laser, thermal transfer and ink-jet printers for diverse applications up to plotters and ensure clear and permanent labelling. On request, Weidmüller also supplies ready-printed markers. An extensive range of materials, e.g. labels, shrink sleeves, cable ties, junction box terminals with the tried-and-tested tension clamp connections as well as lighting terminals for effective wiring is also available. Industrial- Oil & Gas

- Chemical & Petrochemical

- Paper

- Steel

- Pulp & Paper

- Electronic

- Renewable Energy

- Transportation

-

Housing A heavy-duty connector consists of a connector insert and its protective housing. All of Weidmüller's RockStar® housings are made of high-quality die-cast aluminium. Thus they are impact- and corrosion-resistant, yet compact and lightweight. Their patented stainless steel clips make them totally water- and dust-proof. They can be used under the harshest environmental conditions and are resistant to frost and vibrations. Industrial

Housing A heavy-duty connector consists of a connector insert and its protective housing. All of Weidmüller's RockStar® housings are made of high-quality die-cast aluminium. Thus they are impact- and corrosion-resistant, yet compact and lightweight. Their patented stainless steel clips make them totally water- and dust-proof. They can be used under the harshest environmental conditions and are resistant to frost and vibrations. Industrial- Machinery

-

HighPower Kits The RockStar® HighPower housings are manufactured from high-strength die-cast aluminium and offer perfect protection against harsh environmental conditions thanks to continual optimisation. The multi-part housing gives users the opportunity to examine work processes down to the last step in the workflow. Industrial

HighPower Kits The RockStar® HighPower housings are manufactured from high-strength die-cast aluminium and offer perfect protection against harsh environmental conditions thanks to continual optimisation. The multi-part housing gives users the opportunity to examine work processes down to the last step in the workflow. Industrial- Machinery

-

HighPower housings The RockStar® HighPower housings are manufactured from high-strength die-cast aluminium and offer perfect protection against harsh environmental conditions thanks to continual optimisation. The multi-part housing gives users the opportunity to examine work processes down to the last step in the workflow. Industrial

HighPower housings The RockStar® HighPower housings are manufactured from high-strength die-cast aluminium and offer perfect protection against harsh environmental conditions thanks to continual optimisation. The multi-part housing gives users the opportunity to examine work processes down to the last step in the workflow. Industrial- Machinery

-

HighPower end-wall connector The RockStar® HighPower system, with its completely newly developed and coordinated components in three and four pin versions, represents a novel product solution for pluggable energy transmission – failure-free The RockStar® HighPower system has a modular design and offers the customer a multitude of product solutions for all kinds of application sites and requirements. The RockStar® HighPower end-wall connector is impact-resistant, water and dust-proof and was built to comply with DIN EN 61373 CAT 1b (bogie) requirements. The overall structure has been adapted to the confined space of wagon-to-wagon coupling - small, light and powerful Industrial

HighPower end-wall connector The RockStar® HighPower system, with its completely newly developed and coordinated components in three and four pin versions, represents a novel product solution for pluggable energy transmission – failure-free The RockStar® HighPower system has a modular design and offers the customer a multitude of product solutions for all kinds of application sites and requirements. The RockStar® HighPower end-wall connector is impact-resistant, water and dust-proof and was built to comply with DIN EN 61373 CAT 1b (bogie) requirements. The overall structure has been adapted to the confined space of wagon-to-wagon coupling - small, light and powerful Industrial- Machinery

-

HighPower accessories The RockStar® HighPower housings are manufactured from high-strength die-cast aluminium and offer perfect protection against harsh environmental conditions thanks to continual optimisation. The multi-part housing gives users the opportunity to examine work processes down to the last step in the workflow. Industrial

HighPower accessories The RockStar® HighPower housings are manufactured from high-strength die-cast aluminium and offer perfect protection against harsh environmental conditions thanks to continual optimisation. The multi-part housing gives users the opportunity to examine work processes down to the last step in the workflow. Industrial- Machinery

-

High Integrity Pressure Protection System L&T Valves offers a range of customised SIL3-capable High Integrity Pressure Protection Systems (HIPPS) for over-pressure protection In industrial plants, in case of over-pressurisation, the gases released are primarily flared. Flaring and venting of flammable gases pose health and safety hazards and constitute a significant threat to the environment.

High Integrity Pressure Protection System L&T Valves offers a range of customised SIL3-capable High Integrity Pressure Protection Systems (HIPPS) for over-pressure protection In industrial plants, in case of over-pressurisation, the gases released are primarily flared. Flaring and venting of flammable gases pose health and safety hazards and constitute a significant threat to the environment. -

Special Features & Benefits Pressure-seal Globe Valve design conforms to ASME B 16.34. CE Marking – Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment Safety Integrity Level for Automated Valves - SIL 3 certification available Pressure-seal Globe Valves (up to Class 2500) used in Oil & Gas industry tested to ISO 15848-1 Class BH Pressure-seal Globe Valves successfully tested to Shell Design Validation Test 77/300 and witnessed by Shell Inspectors Valves in intermediate classes reduce total cost of ownership Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures. In-situ hardfaced seat design for all sizes Higher hardfacing thickness (3 mm) to ensure consistent hot hardness Body-guided Disc offered in Pressure-seal Globe Valves (all sizes/classes) provides disc stability and avoids vibration of the disc-disc nut assembly Disc guides hardfaced for longer life Customised deposition process in F91/ C12A valves to avoid delamination of hardfaced surfaces Live loading of bonnet bolts for F91/ C12A valves Special high purity graphite packing (seven rings) provided for pressure rating > Class 2500 in Power applications

Special Features & Benefits Pressure-seal Globe Valve design conforms to ASME B 16.34. CE Marking – Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment Safety Integrity Level for Automated Valves - SIL 3 certification available Pressure-seal Globe Valves (up to Class 2500) used in Oil & Gas industry tested to ISO 15848-1 Class BH Pressure-seal Globe Valves successfully tested to Shell Design Validation Test 77/300 and witnessed by Shell Inspectors Valves in intermediate classes reduce total cost of ownership Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures. In-situ hardfaced seat design for all sizes Higher hardfacing thickness (3 mm) to ensure consistent hot hardness Body-guided Disc offered in Pressure-seal Globe Valves (all sizes/classes) provides disc stability and avoids vibration of the disc-disc nut assembly Disc guides hardfaced for longer life Customised deposition process in F91/ C12A valves to avoid delamination of hardfaced surfaces Live loading of bonnet bolts for F91/ C12A valves Special high purity graphite packing (seven rings) provided for pressure rating > Class 2500 in Power applications -

Globe Valves

Globe Valves- Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures.

- In-situ hardfaced seat design for all sizes

- Higher hardfacing thickness (3 mm) to ensure consistent hot hardness

- Body-guided Disc offered in all sizes/classes to provide disc stability and avoids vibration of the disc-disc nut assembly. Disc guides hardfaced for longer life

-

Special Features & Benefits Pressure-seal Gate Valve design conforms to ASME B 16.34. The design was successfully validated by conducting in-house High Pressure High Temperature (HPHT) Gas Tests on ultra-high pressure valve prototypes. Flow Interruption Test successfully conducted on 8" Class 600 Pressure-seal Gate Valve suitable for Main Stream Isolation Valve (MSIV) service in nuclear power plants - at Areva, Germany. Fugitive Emission - 14" Class 2500 Pressure-seal Gate Valve (test pressure of 431 bar at ambient and 289 bar at 400 degree C) has been tested successfully as per ISO 15848-1, endurance Class CO2 and Tightness Class BH CE Marking – Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL3 Safety Integrity Level for Automated Valves Pressure-seal Gate Valves (up to Class 2500) used in Oil & Gas industry tested to ISO 15848-1 Class BH Pressure-seal Gate Valves successfully tested to Shell Design Validation Test 77/300 and witnessed by Shell Inspectors Valves in intermediate classes reduce total cost of ownership Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures. Higher hardfacing thickness (3 mm) to ensure consistent hot hardness Disc guides hardfaced for longer life Customised deposition process in F91/ C12A valves to avoid delamination of hardfaced surfaces Live loading of bonnet bolts for F91/ C12A valves Special high purity graphite packing (seven rings) provided for pressure rating > Class 2500 in Power applications Live loading of bonnet bolts and gland bolts for all valves in F91/ C12A construction

Special Features & Benefits Pressure-seal Gate Valve design conforms to ASME B 16.34. The design was successfully validated by conducting in-house High Pressure High Temperature (HPHT) Gas Tests on ultra-high pressure valve prototypes. Flow Interruption Test successfully conducted on 8" Class 600 Pressure-seal Gate Valve suitable for Main Stream Isolation Valve (MSIV) service in nuclear power plants - at Areva, Germany. Fugitive Emission - 14" Class 2500 Pressure-seal Gate Valve (test pressure of 431 bar at ambient and 289 bar at 400 degree C) has been tested successfully as per ISO 15848-1, endurance Class CO2 and Tightness Class BH CE Marking – Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL3 Safety Integrity Level for Automated Valves Pressure-seal Gate Valves (up to Class 2500) used in Oil & Gas industry tested to ISO 15848-1 Class BH Pressure-seal Gate Valves successfully tested to Shell Design Validation Test 77/300 and witnessed by Shell Inspectors Valves in intermediate classes reduce total cost of ownership Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures. Higher hardfacing thickness (3 mm) to ensure consistent hot hardness Disc guides hardfaced for longer life Customised deposition process in F91/ C12A valves to avoid delamination of hardfaced surfaces Live loading of bonnet bolts for F91/ C12A valves Special high purity graphite packing (seven rings) provided for pressure rating > Class 2500 in Power applications Live loading of bonnet bolts and gland bolts for all valves in F91/ C12A construction -

Special Features & Benefits Gate Valve design complies to API 600, Edition 13 Offered with API 600 monogram Fugitive Emissions - Complies to API 624 and ISO 15848-1 (<50 ppm / Class AH leakage levels, optional) Gate Valves tested to API 624 at Yarmouth Research Lab, Maine, USA Body gasket leakage <100 ppm observed on eight sizes tested as per API 624 Annexure A Fire Safe - By design and tested to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design Examination Certificate (certified by DNV) available ATEX - Meets requirements of ATEX Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL 3 Safety Integrity Level certificatation is available Gate valves successfully tested to Shell Design Validation Test Procedure 77/300 and witnessed by Shell Inspectors Robust stem-wedge design connection successfully tested as per API RP 591 Annex B Hardfaced body guides and wedge slots (sizes >24”) Inconel overlay/ cladded options offered

Special Features & Benefits Gate Valve design complies to API 600, Edition 13 Offered with API 600 monogram Fugitive Emissions - Complies to API 624 and ISO 15848-1 (<50 ppm / Class AH leakage levels, optional) Gate Valves tested to API 624 at Yarmouth Research Lab, Maine, USA Body gasket leakage <100 ppm observed on eight sizes tested as per API 624 Annexure A Fire Safe - By design and tested to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design Examination Certificate (certified by DNV) available ATEX - Meets requirements of ATEX Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL 3 Safety Integrity Level certificatation is available Gate valves successfully tested to Shell Design Validation Test Procedure 77/300 and witnessed by Shell Inspectors Robust stem-wedge design connection successfully tested as per API RP 591 Annex B Hardfaced body guides and wedge slots (sizes >24”) Inconel overlay/ cladded options offered -

Features Size 2" to 72" (50 mm to 1800 mm) ASME Class Class 150 to 2500 Design Standard API 600, API 603, ASME B 16.34 Special Features & Benefit Gate Valve design complies to API 600, Edition 13 Offered with API 600 monogram Fugitive Emissions - Complies to API 624 and ISO 15848-1 (<50 ppm / Class AH leakage levels, optional) Gate Valves tested to API 624 at Yarmouth Research Lab, Maine, USA Body gasket leakage <100 ppm observed on eight sizes tested as per API 624 Annexure A Fire Safe - By design and tested to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design Examination Certificate (certified by DNV) available Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL 3 Safety Integrity Level for Automated Valves Gate valves successfully tested to Shell Design Validation Test Procedure 77/300 and witnessed by Shell Inspectors Robust stem-wedge design connection successfully tested as per API RP 591 Annex B Hardfaced body guides and wedge slots (sizes >24”) Inconel overlay/ cladded options offered

Features Size 2" to 72" (50 mm to 1800 mm) ASME Class Class 150 to 2500 Design Standard API 600, API 603, ASME B 16.34 Special Features & Benefit Gate Valve design complies to API 600, Edition 13 Offered with API 600 monogram Fugitive Emissions - Complies to API 624 and ISO 15848-1 (<50 ppm / Class AH leakage levels, optional) Gate Valves tested to API 624 at Yarmouth Research Lab, Maine, USA Body gasket leakage <100 ppm observed on eight sizes tested as per API 624 Annexure A Fire Safe - By design and tested to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design Examination Certificate (certified by DNV) available Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL 3 Safety Integrity Level for Automated Valves Gate valves successfully tested to Shell Design Validation Test Procedure 77/300 and witnessed by Shell Inspectors Robust stem-wedge design connection successfully tested as per API RP 591 Annex B Hardfaced body guides and wedge slots (sizes >24”) Inconel overlay/ cladded options offered -

Description WTR 2.5/SI

Description WTR 2.5/SI- W-Series, Fuse terminal, Rated cross-section: 2.5 mm², Screw connection

- W-Series, Fuse terminal, Rated cross-section: 4 mm², Screw connection

- W-Series, Fuse terminal with LED 10-36 VDC/AC, Rated cross-section: 4 mm², Screw connection

- W-Series, Fuse terminal with LED 140-250 VDC/AC, Rated cross-section: 4 mm², Screw connection

- W-Series, Fuse terminal, Rated cross-section: 6 mm², Screw connection, FUSE 5X20 mm

- W-Series, Fuse terminal with LED 10-36 VDC/AC, Rated cross-section: 6 mm², Screw connection, FUSE 5X20 mm

- W-Series, Fuse terminal with LED 250 AC, Rated cross-section: 6 mm², Screw connection, FUSE 5X20 mm

-

DescriptionZSI ZSI 2.5

DescriptionZSI ZSI 2.5- Z-series, Fuse terminal, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

- Z-series, Fuse terminal with LED 28VAC, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

- Z-series, Fuse terminal with LED 120VAC, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

- Z-series, Fuse terminal with LED 250VAC, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

-

AFS 2.5 CF 2C BK -Fuse terminal, PUSH IN, 2.5 mm², 250 V, 10 A, Black AFS 2.5 CF 2C 12V BK - Fuse terminal, PUSH IN, 2.5 mm², 12 V, 10 A, Black AFS 2.5 CF 2C 24V BK - Fuse terminal, PUSH IN, 2.5 mm², 24 V, 10 A, Black AFS 4 2C BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black AFS 4 2C 10-36V BK - Fuse terminal, PUSH IN, 4 mm², 36 V, 6.3 A, Black AFS 4 2C 30-70V BK - Fuse terminal, PUSH IN, 4 mm², 70 V, 6.3 A, Black AFS 4 2C 100-250V BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black

AFS 2.5 CF 2C BK -Fuse terminal, PUSH IN, 2.5 mm², 250 V, 10 A, Black AFS 2.5 CF 2C 12V BK - Fuse terminal, PUSH IN, 2.5 mm², 12 V, 10 A, Black AFS 2.5 CF 2C 24V BK - Fuse terminal, PUSH IN, 2.5 mm², 24 V, 10 A, Black AFS 4 2C BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black AFS 4 2C 10-36V BK - Fuse terminal, PUSH IN, 4 mm², 36 V, 6.3 A, Black AFS 4 2C 30-70V BK - Fuse terminal, PUSH IN, 4 mm², 70 V, 6.3 A, Black AFS 4 2C 100-250V BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black -

Functional components The following products are available as functional components: Switch and button components in a sealed built-in EG2 enclosure Rectifier and fuse components in a sealed built-in EG2 enclosure Logic components with AND, NAND, OR and NOR operators Diode gates with up to 40 inputs in open design Components modules for the integration of electronic elements Serial interface converter, and AD / DA converter Industrial

Functional components The following products are available as functional components: Switch and button components in a sealed built-in EG2 enclosure Rectifier and fuse components in a sealed built-in EG2 enclosure Logic components with AND, NAND, OR and NOR operators Diode gates with up to 40 inputs in open design Components modules for the integration of electronic elements Serial interface converter, and AD / DA converter Industrial- Oil & Gas

- Chemical & Petrochemical

- Paper

- Steel

- Pulp & Paper

- Electronic

- Renewable Energy

- Transportation

-

Application Designed to house systems incorporating large components or complex mounting configurations. Three-point latching and sealing provide industry-leading protection from dust, dirt, oil and water. These enclosures are used in machine tool applications for housing motor starters, drives, contactors and PLCs, as well as a wide variety of other electrical and electronic equipment. The addition of 19-in. rack-mounting accessories makes these enclosures ideal for providing rugged protection for sensitive rack-mounted components in harsh industrial environments. These enclosures are used extensively in automotive, pulp and paper, wood products, textile and similar industries. Size 60.06 x 48.06 x 18.06 - 90.06 x 72.06 x 36.06

Application Designed to house systems incorporating large components or complex mounting configurations. Three-point latching and sealing provide industry-leading protection from dust, dirt, oil and water. These enclosures are used in machine tool applications for housing motor starters, drives, contactors and PLCs, as well as a wide variety of other electrical and electronic equipment. The addition of 19-in. rack-mounting accessories makes these enclosures ideal for providing rugged protection for sensitive rack-mounted components in harsh industrial environments. These enclosures are used extensively in automotive, pulp and paper, wood products, textile and similar industries. Size 60.06 x 48.06 x 18.06 - 90.06 x 72.06 x 36.06 -

Application These enclosures are ideal for mounting equipment on panels or racks in indoor or outdoor applications where it is necessary to protect controls and instrumentation from wet, non-corrosive environments. The design features Hoffman’s exclusive PowerGlide Handle with 3-point latching for secure closure. Size 72.06 x 25.06 x 18.06 - 72.06 x 37.06 x 24.06

Application These enclosures are ideal for mounting equipment on panels or racks in indoor or outdoor applications where it is necessary to protect controls and instrumentation from wet, non-corrosive environments. The design features Hoffman’s exclusive PowerGlide Handle with 3-point latching for secure closure. Size 72.06 x 25.06 x 18.06 - 72.06 x 37.06 x 24.06 -

Application Designed to house systems incorporating large components or complex mounting configurations. Three-point latching and sealing provide industry-leading protection from dust, dirt, oil and water. These enclosures are used in machine tool applications for housing motor starters, drives, contactors and PLCs, as well as a wide variety of other electrical and electronic equipment. The addition of 19-in. rack-mounting accessories makes these enclosures ideal for providing rugged protection for sensitive rack-mounted components in harsh industrial environments. These enclosures are used extensively in automotive, pulp and paper, wood products, textile and similar industries. Four styles are available to provide maximum flexibility Size 60.06 x 24.06 x 18.06 - 90.06 x 36.06 x 36.06

Application Designed to house systems incorporating large components or complex mounting configurations. Three-point latching and sealing provide industry-leading protection from dust, dirt, oil and water. These enclosures are used in machine tool applications for housing motor starters, drives, contactors and PLCs, as well as a wide variety of other electrical and electronic equipment. The addition of 19-in. rack-mounting accessories makes these enclosures ideal for providing rugged protection for sensitive rack-mounted components in harsh industrial environments. These enclosures are used extensively in automotive, pulp and paper, wood products, textile and similar industries. Four styles are available to provide maximum flexibility Size 60.06 x 24.06 x 18.06 - 90.06 x 36.06 x 36.06 -

Features TD Compact Four Pole Distribution Block

Features TD Compact Four Pole Distribution Block- Minimum space for maximum power

- Protection cover and insulating screens are transparent

- Insulating screen between each row

- Easy and safe connections

- Easily clips onto DIN rail or mounts to panel with screws

- Solid bars provide reliability

- Wiring with or without terminal

- Halogen free

- RoHS compliant

- Connect nVent ERIFLEX Flexibar, insulated braided conductor or cable with lug on line side

- Tinned copper bars allows for copper or aluminum cable

- Transparent protection covers

- Easy and safe connections

- Easily clips onto DIN rail or mounts to panel with screws

- Solid bars provide reliability

- Input separated from outputs

- Supports wiring from both sides

- Design allows for visual inspection of conductor and confirmation of connection

- Large end terminals

- High percentange of fill ratio

- Wiring with or without terminal

- Halogen free

- RoHS compliant

- Attaches to four pole distribution blocks for increased wire capacity

- Direct electrical connection

- Strong mechanical assembly

- Transparent protection cover

- Halogen free

- RoHS compliant

-

Features Floating Ball Valves Size 1/2" to 8" | ASME Class Class 150 to 2500 ISO 17292 | API 6D | API 608 1 Piece / 2 Piece / 3 Piece Construction Full / Reduced bore Soft Seat & Metal seat | Flanged-Screwed-Socket weld

Features Floating Ball Valves Size 1/2" to 8" | ASME Class Class 150 to 2500 ISO 17292 | API 6D | API 608 1 Piece / 2 Piece / 3 Piece Construction Full / Reduced bore Soft Seat & Metal seat | Flanged-Screwed-Socket weld- Mirror-finished solid stainless ball

- Fine-grained PTFE seats with Cavity Pressure Relief mechanism

- Blowout-proof stem & Antistatic feature

- High integrity stem sealing – Belleville springs compensate for wear and thermal expansions

- Actuator-mounting flange conforms to ISO 5211