-

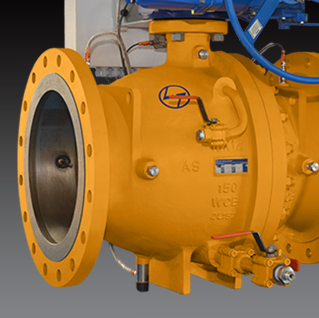

Features L&T Valves launches a smart flow-control solution that enhances plant safety and reliability - L&T Valves Asset Management Program, LAMP. This IoT-ready remote valve performance monitoring system leverages expertise in valve manufacture as well as system design and integration. At the core of LAMP is a time-tested SIL3-capable valve - Ball, Butterfly, DBB Plug, Gate or Globe. Each valve is equipped with ValvTrac™ digital traceability tag that cross-links valve signature to traceability information such as valve test certificates, material test certificates, and installation, operation and maintenance manuals. The valves are upgraded to ‘Smart Valves’ by integrating them with next-generation smart sensors that measure parameters such as torque, leakage, vibration, pressure, temperature and position. The data is relayed real-time to a secure, dedicated cloud computing platform where it is analyzed to provide complete valve health and diagnostic information. Valve users can access information through a secure login, or port the data to the native asset management system through any standard field communication protocol (HART, WirelessHART, Foundation Fieldbus, etc.). To a customer, knowledge is trust; the more he knows about the state of a valve, the more confident can he be about its performance. Thus LAMP takes the guesswork out of valve maintenance and allows customers to transition from preventive maintenance based on thumb rules to predictive maintenance based on real data.

Features L&T Valves launches a smart flow-control solution that enhances plant safety and reliability - L&T Valves Asset Management Program, LAMP. This IoT-ready remote valve performance monitoring system leverages expertise in valve manufacture as well as system design and integration. At the core of LAMP is a time-tested SIL3-capable valve - Ball, Butterfly, DBB Plug, Gate or Globe. Each valve is equipped with ValvTrac™ digital traceability tag that cross-links valve signature to traceability information such as valve test certificates, material test certificates, and installation, operation and maintenance manuals. The valves are upgraded to ‘Smart Valves’ by integrating them with next-generation smart sensors that measure parameters such as torque, leakage, vibration, pressure, temperature and position. The data is relayed real-time to a secure, dedicated cloud computing platform where it is analyzed to provide complete valve health and diagnostic information. Valve users can access information through a secure login, or port the data to the native asset management system through any standard field communication protocol (HART, WirelessHART, Foundation Fieldbus, etc.). To a customer, knowledge is trust; the more he knows about the state of a valve, the more confident can he be about its performance. Thus LAMP takes the guesswork out of valve maintenance and allows customers to transition from preventive maintenance based on thumb rules to predictive maintenance based on real data. -

Description The FCX-AIII level transmitter accurately measures liquid level and transmits a proportional 4 to 20 mA signal. The transmitter utilizes a unique micromachined capacitance silicon sensor with state-of-the-art microprocessor technology to provide exceptional performance and functionality. Industrial

Description The FCX-AIII level transmitter accurately measures liquid level and transmits a proportional 4 to 20 mA signal. The transmitter utilizes a unique micromachined capacitance silicon sensor with state-of-the-art microprocessor technology to provide exceptional performance and functionality. Industrial- Oil & Gas

- Pulp & Paper

-

Description This water level transmitter is used for measuring the level of clean water, sewage water, well, river, etc. The detector is placed on the bottom of the water, and the water head pressure acting on the pressure receiving diaphragm is detected, converted into a current signal and then transmitted to a receiving instrument via the connector terminal. Industrial

Description This water level transmitter is used for measuring the level of clean water, sewage water, well, river, etc. The detector is placed on the bottom of the water, and the water head pressure acting on the pressure receiving diaphragm is detected, converted into a current signal and then transmitted to a receiving instrument via the connector terminal. Industrial- Oil & Gas

- Pulp & Paper

-

Lightning and surge protection (SPD) The priority you give to overvoltage protection depends on your willingness to take risks! Perhaps you think "it’ll never happen to me". Then you won’t have lost anything, but will have gained only very little. However, the subject of overvoltage is then a daily worry for you. But if you wish to be on the safe side, you should include overvoltage protection in your corporate strategy. You will profit from such an investment in operational safety and can prevent a disaster with Weidmüller's surge protection for power, signal and data. Industrial

Lightning and surge protection (SPD) The priority you give to overvoltage protection depends on your willingness to take risks! Perhaps you think "it’ll never happen to me". Then you won’t have lost anything, but will have gained only very little. However, the subject of overvoltage is then a daily worry for you. But if you wish to be on the safe side, you should include overvoltage protection in your corporate strategy. You will profit from such an investment in operational safety and can prevent a disaster with Weidmüller's surge protection for power, signal and data. Industrial- Oil & Gas

- Chemical & Petrochemical

- Paper

- Steel

- Pulp & Paper

- Electronic

- Renewable Energy

- Transportation

-

M12 distributor Passive M12 distributors are available in all conceivable forms and configurations. Furthermore, a number of special versions, e.g. SAI distributors for EX zones or the ergonomic M8, are available only from Weidmüller. These innovative products are backed up by numerous proprietary rights. Industrial Machinery, device manufacturer

M12 distributor Passive M12 distributors are available in all conceivable forms and configurations. Furthermore, a number of special versions, e.g. SAI distributors for EX zones or the ergonomic M8, are available only from Weidmüller. These innovative products are backed up by numerous proprietary rights. Industrial Machinery, device manufacturer -

M5 distributor Besides being extremely compact, these modules are also very low in weight. But they are still amazingly easy to handle. M5 distributors are supplied as 4- and 8-way modules each with M12, M16 or fixed cable outlets. The plug-in connectors are in 3 or 4 pole design. Marking: Each plug-in station is identified with the plug-in station number. Every initiator LED can be allocated precisely with the letters A and B. Moreover, the distributor and every connection position can be labelled if required. Industrial Machinery, device manufacturer

M5 distributor Besides being extremely compact, these modules are also very low in weight. But they are still amazingly easy to handle. M5 distributors are supplied as 4- and 8-way modules each with M12, M16 or fixed cable outlets. The plug-in connectors are in 3 or 4 pole design. Marking: Each plug-in station is identified with the plug-in station number. Every initiator LED can be allocated precisely with the letters A and B. Moreover, the distributor and every connection position can be labelled if required. Industrial Machinery, device manufacturer -

M8 distributor The new slim M8 line from Weidmüller. This range of products is characterised by the marking options at all connection positions. Even the 4-way distributor with 8-pole M12 has adequately large markers at all M8 connection positions. Furthermore, this distributor is shorter than many conventional M8 designs. Very narrow, short and flat M8 distributor. The range is supplied with 4 to 12 M8 connection positions, 3 or 4 poles. Hybrid variants of the M8 are also possible on request. The M8 line is equipped with transverse holes. Industrial Machinery, device manufacturer

M8 distributor The new slim M8 line from Weidmüller. This range of products is characterised by the marking options at all connection positions. Even the 4-way distributor with 8-pole M12 has adequately large markers at all M8 connection positions. Furthermore, this distributor is shorter than many conventional M8 designs. Very narrow, short and flat M8 distributor. The range is supplied with 4 to 12 M8 connection positions, 3 or 4 poles. Hybrid variants of the M8 are also possible on request. The M8 line is equipped with transverse holes. Industrial Machinery, device manufacturer -

Markings

Markings- DEK 5/5 Plus MC (1 sheet=100 tag)

- DEK 5/5 Plus MC (1 sheet=100 tag)

- WS 12/5 MC (1 sheet = 72 tags)

-

· Size mm. : 63 · For corrosive gasses and liquids · Class 1.6 according to EN 837-1 · Wetted parts Stainless steel (MEX) or Monel (MEM) · Lloyd`s Register approval · Option : liquid-filled for applications with pulsations or vibrations · Option : case material 1.4404 (316L) for aggressive atmosphere

· Size mm. : 63 · For corrosive gasses and liquids · Class 1.6 according to EN 837-1 · Wetted parts Stainless steel (MEX) or Monel (MEM) · Lloyd`s Register approval · Option : liquid-filled for applications with pulsations or vibrations · Option : case material 1.4404 (316L) for aggressive atmosphere -

- Series: MEP5 - Size 100 mm - For corrosive gasses and liquids - Class 1 according to EN 837-1 - Wetted parts Stainless steel (MEP) or Monel (MMN) - Lloyds Register Approval - Safety version S3 according to EN 837-1 - Option : liquid-filled for applications with pulsations or vibrations - Option : case material 1.4404 (316L) for aggressive atmosphere

- Series: MEP5 - Size 100 mm - For corrosive gasses and liquids - Class 1 according to EN 837-1 - Wetted parts Stainless steel (MEP) or Monel (MMN) - Lloyds Register Approval - Safety version S3 according to EN 837-1 - Option : liquid-filled for applications with pulsations or vibrations - Option : case material 1.4404 (316L) for aggressive atmosphere -

· Size mm. : 63 · For corrosive gasses and liquids · Class 1.6 according to EN 837-1 · Wetted parts: Stainless steel · Case with crimped bezel ring · Lloyds Register Approval · Option: Liquid-filled for applications with pulsations or vibrations · Option: Case material 1.4404 (316L) for aggressive atmosphere

· Size mm. : 63 · For corrosive gasses and liquids · Class 1.6 according to EN 837-1 · Wetted parts: Stainless steel · Case with crimped bezel ring · Lloyds Register Approval · Option: Liquid-filled for applications with pulsations or vibrations · Option: Case material 1.4404 (316L) for aggressive atmosphere -

Pressure gauge with contact Series: MG5 (With inductive contact) Size 100 mm - For corrosive gasses and liquids - Class 1 according to EN 837-1 - Inductive contacts with sensor according to EN 60947-5-6 (NAMUR) - Option : liquid-filled for applications with pulsations or vibrations - Option: case material 1.4404 (316L) for aggressive atmosphere

Pressure gauge with contact Series: MG5 (With inductive contact) Size 100 mm - For corrosive gasses and liquids - Class 1 according to EN 837-1 - Inductive contacts with sensor according to EN 60947-5-6 (NAMUR) - Option : liquid-filled for applications with pulsations or vibrations - Option: case material 1.4404 (316L) for aggressive atmosphere -

Application Use stylish Concept EMC Enclosures with their convenient quarter-turn latches in indoor or outdoor applications to contain stray electromagnetic interference (EMI) signals produced by internal components and to shield those components from external EMI/RFI interference. Size 10.20 x 10.20 - 34.20 x 22.20

Application Use stylish Concept EMC Enclosures with their convenient quarter-turn latches in indoor or outdoor applications to contain stray electromagnetic interference (EMI) signals produced by internal components and to shield those components from external EMI/RFI interference. Size 10.20 x 10.20 - 34.20 x 22.20