-

ELECTRONIC The Electronics Department develops and markets electronic components for industrial automation, process automation and energy production. These components are used both inside and outside of the electrical cabinet. The focus of the electronics sector is on processing digital and analogue signals. These signals can be converted, standardised, protected and prepared for communication. For these purposes, we offer signal converters and input/output devices for Fieldbus communications based on Industrial Ethernet and Fieldbus. Product solutions are also available for the following fields: surge protection, protecting and amplifying digital signals, supplying devices inside and outside of the electrical cabinet, Ethernet data communication and for pre-assembled system cables. All of these products feature a mechanically convenient installation process, an optimised handling of electrical connections and safe wire connections. The products themselves are well suited for harsh industrial applications. They are suitable for use in a large range of operating temperatures and feature excellent resistance against electromagnetic interference. With this portfolio, the Electronics Department features products which cover the full industrial applications spectrum for the transferring and conditioning of power, signals and data.

ELECTRONIC The Electronics Department develops and markets electronic components for industrial automation, process automation and energy production. These components are used both inside and outside of the electrical cabinet. The focus of the electronics sector is on processing digital and analogue signals. These signals can be converted, standardised, protected and prepared for communication. For these purposes, we offer signal converters and input/output devices for Fieldbus communications based on Industrial Ethernet and Fieldbus. Product solutions are also available for the following fields: surge protection, protecting and amplifying digital signals, supplying devices inside and outside of the electrical cabinet, Ethernet data communication and for pre-assembled system cables. All of these products feature a mechanically convenient installation process, an optimised handling of electrical connections and safe wire connections. The products themselves are well suited for harsh industrial applications. They are suitable for use in a large range of operating temperatures and feature excellent resistance against electromagnetic interference. With this portfolio, the Electronics Department features products which cover the full industrial applications spectrum for the transferring and conditioning of power, signals and data. -

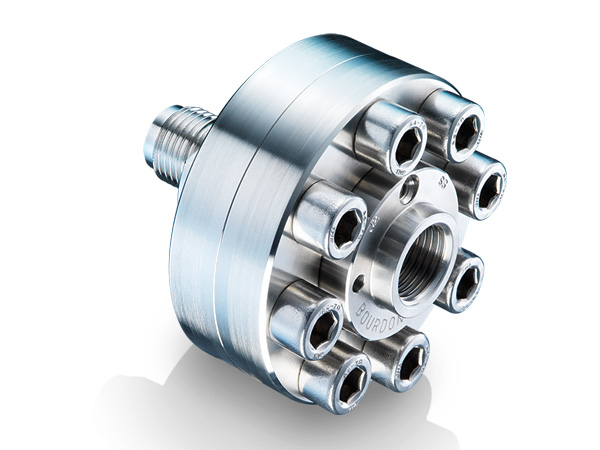

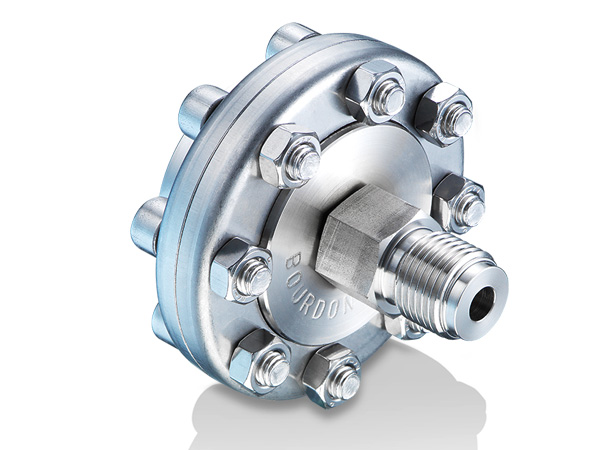

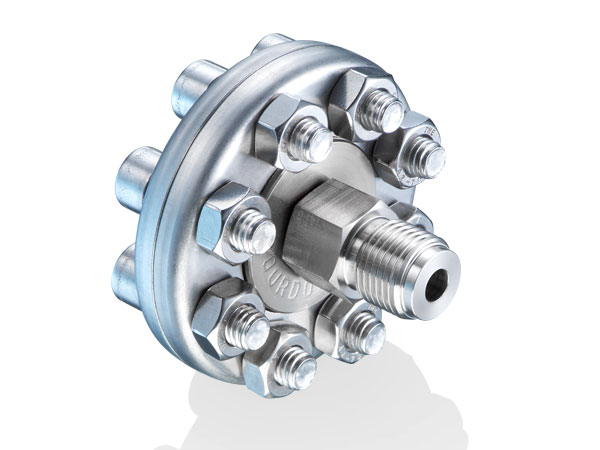

Special Features & Benefits Design complies to API 6D Valves offered with API 6D monogram Fugitive emissions – Complies to ISO 15848-1 Fire safety - Complies to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design examination certificate (certified by DNV) available Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL3 - Safety Integrity Level SIL3 certification complies to IEC 61508 L&T Valves Double Block & Bleed Plug Valve provides online-verifiable bubble tight sealing and is a safe and reliable replacement to the conventional two-valve system High integrity positive shut-off obtained independent of line pressure, without sealants/ lubricants Mechanical sealing ensuring online-verifiable positive double isolation for critical services Patented operator mechanism enables segments to move towards the seats during valve operation – reduces wear and tear and enhances service life Inbuilt cavity pressure relief system Inline Maintainable Seats -Seats can be renewed without removing the valve from the pipeline (after draining and isolating the line)

Special Features & Benefits Design complies to API 6D Valves offered with API 6D monogram Fugitive emissions – Complies to ISO 15848-1 Fire safety - Complies to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design examination certificate (certified by DNV) available Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL3 - Safety Integrity Level SIL3 certification complies to IEC 61508 L&T Valves Double Block & Bleed Plug Valve provides online-verifiable bubble tight sealing and is a safe and reliable replacement to the conventional two-valve system High integrity positive shut-off obtained independent of line pressure, without sealants/ lubricants Mechanical sealing ensuring online-verifiable positive double isolation for critical services Patented operator mechanism enables segments to move towards the seats during valve operation – reduces wear and tear and enhances service life Inbuilt cavity pressure relief system Inline Maintainable Seats -Seats can be renewed without removing the valve from the pipeline (after draining and isolating the line) -

DMS 3K Annunciator The AMETEK DMS 3K is a flexible, remote alarm management system. It captures alarms from digital or analog inputs, displays alarms on the built-in web server and provides outputs to remote annunciator displays and other devices using serial and Ethernet communications. Alarms can be time stamped to the millisecond for sequential events recording and email notification can be provided for critical events.

DMS 3K Annunciator The AMETEK DMS 3K is a flexible, remote alarm management system. It captures alarms from digital or analog inputs, displays alarms on the built-in web server and provides outputs to remote annunciator displays and other devices using serial and Ethernet communications. Alarms can be time stamped to the millisecond for sequential events recording and email notification can be provided for critical events. -

Distributor with integrated logic SAI – logic module These devices allow the combination of signals by means of an AND or an OR gate. This function leads to a reduction in the amount of wiring. The required inputs to the PLC can be reduced by up to 6 inputs. This process therefore saves the amount of wiring and material in the field. Industrial Machinery, device manufacturer

Distributor with integrated logic SAI – logic module These devices allow the combination of signals by means of an AND or an OR gate. This function leads to a reduction in the amount of wiring. The required inputs to the PLC can be reduced by up to 6 inputs. This process therefore saves the amount of wiring and material in the field. Industrial Machinery, device manufacturer -

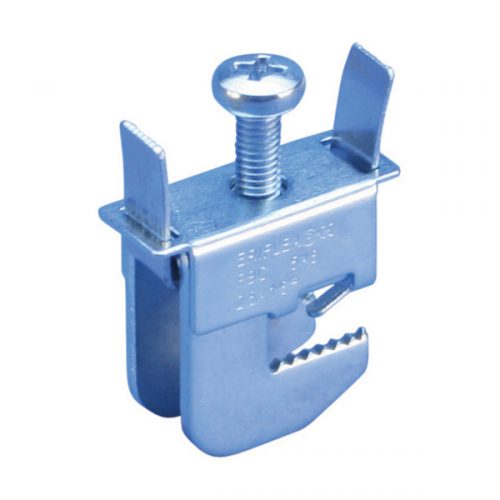

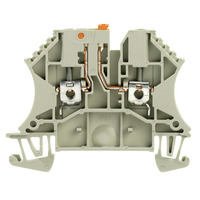

WTR 2.5

WTR 2.5- Test-disconnect terminal, Screw connection, 2.5 mm², 500 V, 24 A, Pivoting, Dark Beige

- Test-disconnect terminal, Screw connection, 2.5 mm², 500 V, 24 A, Pivoting, Blue

- Test-disconnect terminal, Screw connection, 4 mm², 400 V, 32 A, Pivoting, Dark Beige

- Test-disconnect terminal, Screw connection, 4 mm², 400 V, 32 A, Pivoting, Blue

-

Cutting Weidmüller is a specialist in the cutting of copper or aluminium cables. The range of products extends from cutters for small cross-sections with direct force application right up to cutters for large diameters. The mechanical operation and the specially designed cutter shape minimise the effort required. With its wide range of cutting products, Weidmüller meets all the criteria for professional cable processing. Industrial

Cutting Weidmüller is a specialist in the cutting of copper or aluminium cables. The range of products extends from cutters for small cross-sections with direct force application right up to cutters for large diameters. The mechanical operation and the specially designed cutter shape minimise the effort required. With its wide range of cutting products, Weidmüller meets all the criteria for professional cable processing. Industrial- Oil & Gas

- Chemical & Petrochemical

- Paper

- Steel

- Pulp & Paper

- Electronic

- Renewable Energy

- Transportation

-

Description ZQV 2.5/10 GE

Description ZQV 2.5/10 GE- Z-series, Accessories,cross connection for ZDU 2.5, ZDK 2.5, ZTR 2.5 (10 poles)

- Z-series, Accessories,cross connection for ZDU 4(10 poles)

- Z-series, Accessories,cross connection for ZDU 6(24 poles)

- Z-series, Accessories,cross connection for ZDU 10(24poles)

- Z-series, Accessories,cross connection for ZDU 10( 2 poles)

- Z-series, Accessories,cross connection for ZDU 35 ( 2 poles)

-

PZ 1.5 Description of article: Crimping tool for non-insulated connectors, 0.5-6 mm² PZ 6/5 Description of article: Crimping tool for non-insulated connectors, 0.5-6 mm² PZ 6 ROTO Description of article:Crimping tool, Crimping tool for wire-end ferrules, 0.14mm², 6mm², Trapezoidal crimp PZ 10 HEX Description of article: 0.14mm², 10mm², Hexagonal crimping PZ 16 Description of article: Crimping tool, Crimping tool for wire-end ferrules, 6mm², 16mm², Indent crimping PZ 50 Description of article:Crimping tool, Crimping tool for wire-end ferrules, 25mm², 50mm², Indent crimping

PZ 1.5 Description of article: Crimping tool for non-insulated connectors, 0.5-6 mm² PZ 6/5 Description of article: Crimping tool for non-insulated connectors, 0.5-6 mm² PZ 6 ROTO Description of article:Crimping tool, Crimping tool for wire-end ferrules, 0.14mm², 6mm², Trapezoidal crimp PZ 10 HEX Description of article: 0.14mm², 10mm², Hexagonal crimping PZ 16 Description of article: Crimping tool, Crimping tool for wire-end ferrules, 6mm², 16mm², Indent crimping PZ 50 Description of article:Crimping tool, Crimping tool for wire-end ferrules, 25mm², 50mm², Indent crimping -

After stripping the insulation, a suitable contact or wire end ferrule can be crimped onto the end of the cable. Crimping forms a secure connection between conductor and contact and has largely replaced soldering. Crimping denotes the creation of a homogeneous, permanent connection between conductor and connecting element. The connection can be made only with high-quality precision tools. The result is a secure and reliable connection both in mechanical and electrical terms. Weidmüller offers a wide range of mechanical crimping tools. Integral ratchets with release mechanisms guarantee optimum crimping. Crimped connections made with Weidmüller tools comply with international standards and regulations.

After stripping the insulation, a suitable contact or wire end ferrule can be crimped onto the end of the cable. Crimping forms a secure connection between conductor and contact and has largely replaced soldering. Crimping denotes the creation of a homogeneous, permanent connection between conductor and connecting element. The connection can be made only with high-quality precision tools. The result is a secure and reliable connection both in mechanical and electrical terms. Weidmüller offers a wide range of mechanical crimping tools. Integral ratchets with release mechanisms guarantee optimum crimping. Crimped connections made with Weidmüller tools comply with international standards and regulations. -

Crimp contacts The heart of a connector is its contacts. They make up the actual connection between two conductors. For this purpose, two contact types are necessary - plugs and sockets. The plug (male) implements the electrical connection along its outer surface. It is inserted into the socket, which conducts the electrical connection along the surface of its interior side. Weidmüller offers crimp contacts made with different surfaces: gold or silver. Industrial

Crimp contacts The heart of a connector is its contacts. They make up the actual connection between two conductors. For this purpose, two contact types are necessary - plugs and sockets. The plug (male) implements the electrical connection along its outer surface. It is inserted into the socket, which conducts the electrical connection along the surface of its interior side. Weidmüller offers crimp contacts made with different surfaces: gold or silver. Industrial- Machinery