Features

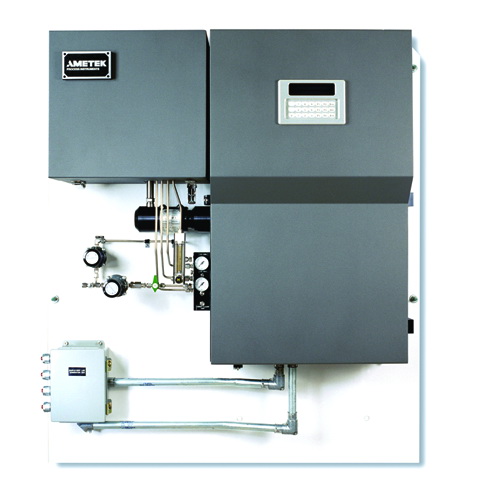

The 3050 Moisture Analyzer series measures trace levels of moisture in a gas through the use of a quartz-crystal oscillator sample cell. AMETEK is the leader in quartz-crystal technology, which for thirty years has offered significant advantages over other measurement techniques:

• Most accurate trace moisture measurement technology available

• Responds far faster to both increasing and decreasing moisture levels

• Specific to moisture in most applications

• Provides a much more rugged sensor

Because of these advantages, the quartz-crystal oscillator has become the industry standard for applications ranging from ultrahigh purity semiconductor gases to natural gas streams containing 30% H2S. Now, the 3050 analyzers bring the benefits of quartz-crystal technology to a broad spectrum of moisture applications.

AME Vision Display Unit

AMEVision allows users to continually monitor the measurement and diagnostic information from up to eight 3050 series moisture analyzers. AMEVision provides real-time moisture measurements, trend data, and details a variety of maintenance and troubleshooting information from the 3050. Users can communicate with AMEVision via Modbus RS485 and Ethernet LAN.

• Compatible with 3050 models OLV, SLR, DO, and TE

• Connect up to eight analyzers on one unit

• Trend history

• Automatic data capture and logging

• Calibration history

• Alarm history

Industrial

- Oil & Gas

- Chemical & Petrochemical