-

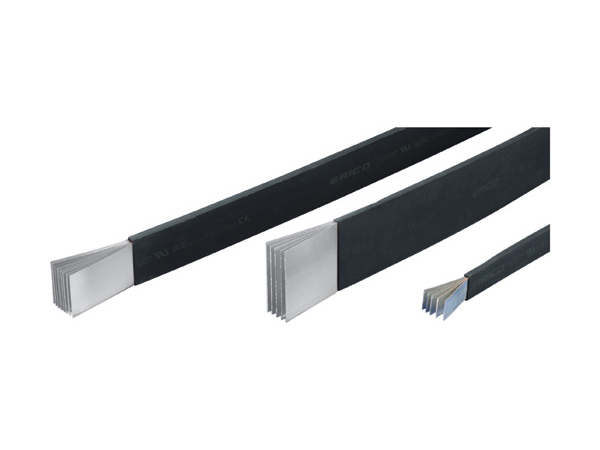

Flexible heaters are very versatile and provide solutions to a vast number of low-to-medium temperature applications. Heaters are manufactured with rugged light-weight materials providing chemical and moisture resistance with operating temperatures to 392°F. Wire elements are durable and wound precisely within the structure for optimal performance. A variety of electrical, shape and contour fittings to meet many specifications.

Flexible heaters are very versatile and provide solutions to a vast number of low-to-medium temperature applications. Heaters are manufactured with rugged light-weight materials providing chemical and moisture resistance with operating temperatures to 392°F. Wire elements are durable and wound precisely within the structure for optimal performance. A variety of electrical, shape and contour fittings to meet many specifications. -

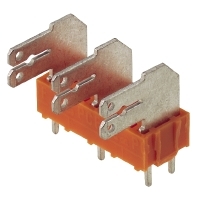

Flat-blade connection The traditional single-wire connection – versatile, simple and cost-effective: PCB terminals with cable-lug connection – the PCF system. High current-carrying capacity up to 24 A (IEC) or 15 A (UL) 3 pitches (5.0 / 7.5 / 10.0 mm) for voltages up to 1000 V (IEC) or 300 V (UL) 3 outlet directions in relation to the PCB (90 / 135 / 180°) For mounting side by side or fixed number of poles, between 2 and 19 connector lugs Can be used with 2.8 and 6.3 mm flat blade receptacles Suitable for insulated and uninsulated receptacles For applications requiring the quick and easy connection of pre-assembled conductors to PCBs. A simple solution for simple connections: inexpensive Faston connection system for PCBs. Industrials

Flat-blade connection The traditional single-wire connection – versatile, simple and cost-effective: PCB terminals with cable-lug connection – the PCF system. High current-carrying capacity up to 24 A (IEC) or 15 A (UL) 3 pitches (5.0 / 7.5 / 10.0 mm) for voltages up to 1000 V (IEC) or 300 V (UL) 3 outlet directions in relation to the PCB (90 / 135 / 180°) For mounting side by side or fixed number of poles, between 2 and 19 connector lugs Can be used with 2.8 and 6.3 mm flat blade receptacles Suitable for insulated and uninsulated receptacles For applications requiring the quick and easy connection of pre-assembled conductors to PCBs. A simple solution for simple connections: inexpensive Faston connection system for PCBs. Industrials- Electronic

- Other

-

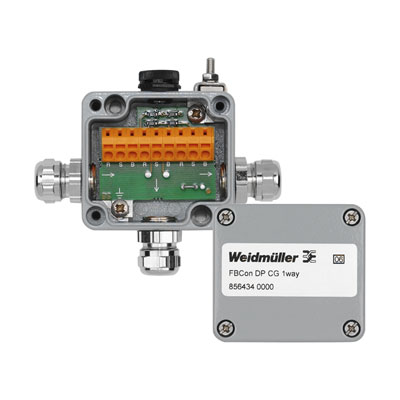

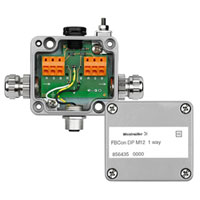

Field bus components The FBCon Fieldbus distributor is available in the industry and EEx (ia) version. They are used for coupling from 1 to 8 field devices or sensors. They are connected via spur lines. The connection to the spur line can be made with an M12 plug or directly via an EMC cable gland. Communication and device power feed are transferred by a common 2-wire line. The distributors offer the following features respective of the version: Tension-clamp connection system Overvoltage protection for the main line Current limiter for each branch line EMC cable gland M12 plug-in connectors External earthing contact Interruption-free bus operation Industrial version Bus termination integrated (not EX) ATEX explosion-proof version Pressure-equalising element Protection degrees IP65, IP66, IP67 Stainless steel versions PROFIBUS-PA compatible Industrial

Field bus components The FBCon Fieldbus distributor is available in the industry and EEx (ia) version. They are used for coupling from 1 to 8 field devices or sensors. They are connected via spur lines. The connection to the spur line can be made with an M12 plug or directly via an EMC cable gland. Communication and device power feed are transferred by a common 2-wire line. The distributors offer the following features respective of the version: Tension-clamp connection system Overvoltage protection for the main line Current limiter for each branch line EMC cable gland M12 plug-in connectors External earthing contact Interruption-free bus operation Industrial version Bus termination integrated (not EX) ATEX explosion-proof version Pressure-equalising element Protection degrees IP65, IP66, IP67 Stainless steel versions PROFIBUS-PA compatible Industrial- Oil & Gas

- Chemical & Petrochemical

- Paper

- Steel

- Pulp & Paper

- Electronic

- Renewable Energy

- Transportation

-

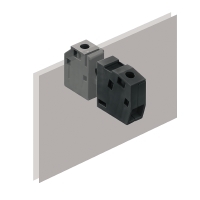

6 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. The innovative PUSH IN connection system from Weidmüller makes for a simple, tool-free wire connection on the inside and outside of devices. The sliced design and an intuitive fastening mechanism enable high-density blocks to be constructed quickly and easily. Industrial

6 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. The innovative PUSH IN connection system from Weidmüller makes for a simple, tool-free wire connection on the inside and outside of devices. The sliced design and an intuitive fastening mechanism enable high-density blocks to be constructed quickly and easily. Industrial- Electronic

- Other

-

25 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. Various types of connection on the inside, such as cable lug connections which can be encapsulated (WGK …VP) and maintenance-free clamping yoke screw connections (WGK…) with vertical and horizontal wire insertion provide the optimal connection for any installation situation. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial

25 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. Various types of connection on the inside, such as cable lug connections which can be encapsulated (WGK …VP) and maintenance-free clamping yoke screw connections (WGK…) with vertical and horizontal wire insertion provide the optimal connection for any installation situation. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial- Electronic

- Other

-

16 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. Different types of connection on the inside, such as a solder connection which can be encapsulated (WGK …VP) or a maintenance-free clamping yoke screw connection (WGK…) with vertical and horizontal wire connections, provide the optimal connection for any installation situation. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial

16 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. Different types of connection on the inside, such as a solder connection which can be encapsulated (WGK …VP) or a maintenance-free clamping yoke screw connection (WGK…) with vertical and horizontal wire connections, provide the optimal connection for any installation situation. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial- Electronic

- Other

-

10 mm² : Optimal connection options for use in encapsulated devices (e.g. EMC filters and/or fully insulated transformers) The V versions of the WGK feed-through terminals with an insulated housing and clamping yoke connection on the outside, and a solder connection on the inside. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial

10 mm² : Optimal connection options for use in encapsulated devices (e.g. EMC filters and/or fully insulated transformers) The V versions of the WGK feed-through terminals with an insulated housing and clamping yoke connection on the outside, and a solder connection on the inside. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial- Electronic

- Other

-

Feedthrough terminals for devices - OMNIMATE Power The universal solution to feed power through housing walls. Excellent for applications such as EMC filters, discrete-built inverters for drive systems and encapsulated devices. Select from our wide-ranging programme: · 4 mm²A wide service portfolio for currents up to 232 A and conductor cross-sections from 4 to 95 mm² (AWG 4/0) · Different types of connections such as a castable soldering connection, cable lug bolt connection and service-free clamping yoke screw connection and PUSH IN spring connection · Structural shapes for horizontal or vertical outgoing cable Industrial

Feedthrough terminals for devices - OMNIMATE Power The universal solution to feed power through housing walls. Excellent for applications such as EMC filters, discrete-built inverters for drive systems and encapsulated devices. Select from our wide-ranging programme: · 4 mm²A wide service portfolio for currents up to 232 A and conductor cross-sections from 4 to 95 mm² (AWG 4/0) · Different types of connections such as a castable soldering connection, cable lug bolt connection and service-free clamping yoke screw connection and PUSH IN spring connection · Structural shapes for horizontal or vertical outgoing cable Industrial- Electronic

- Other

-

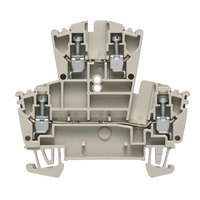

Description WDK 2.5

Description WDK 2.5- Feed-through terminal, Double-tier terminal, Screw connection, 2.5 mm², 400 V, 24 A, Dark Beige

- Feed-through terminal, Double-tier terminal, Screw connection, 2.5 mm², 400 V, 24 A, Blue

- Feed-through terminal, Double-tier terminal, Screw connection, 10 mm², 800 V, 57 A, Dark Beige

- Feed-through terminal, Double-tier terminal, Screw connection, 10 mm², 800 V, 57 A, Blue

-

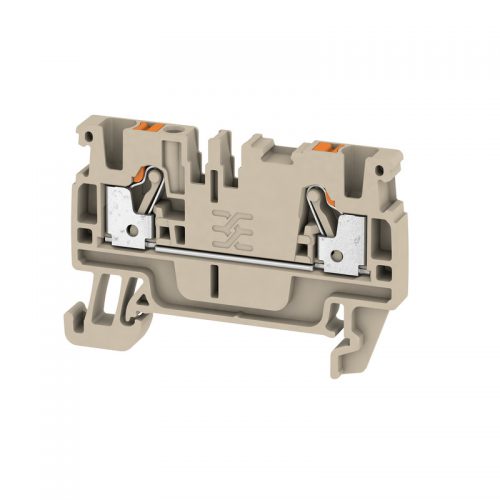

Description WDU 2.5

Description WDU 2.5- Feed-through terminal, Screw connection, 2.5 mm², 800 V, 24 A, Dark Beige

- Feed-through terminal, Screw connection, 2.5 mm², 800 V, 24 A, Blue

- W-Series, Feed-through terminal, Thermocouple TYPE K, Rated cross-section: 2.5 mm², Screw connection

- Feed-through terminal, Screw connection, 4 mm², 800 V, 32 A, Dark Beige

- Feed-through terminal, Screw connection, 4 mm², 800 V, 32 A, Blue

- Feed-through terminal, Screw connection, 6 mm², 800 V, 41 A, Dark Beige

- Feed-through terminal, Screw connection, 6 mm², 800 V, 41 A, Blue

- Feed-through terminal, Screw connection, 10 mm², 1000 V, 57 A, Dark Beige

- Feed-through terminal, Screw connection, 10 mm², 1000 V, 57 A, Blue

- Feed-through terminal, Screw connection, 16 mm², 1000 V, 76 A, Dark Beige

- Feed-through terminal, Screw connection, 16 mm², 1000 V, 76 A, Blue

- Feed-through terminal, Screw connection, 35 mm², 1000 V, 125 A, Dark Beige

- Feed-through terminal, Screw connection, 35 mm², 1000 V, 125 A, Blue

- Feed-through terminal, Screw connection, 50 mm², 1000 V, 150 A, Dark Beige

- Feed-through terminal, Screw connection, 50 mm², 1000 V, 150 A, Blue

- Feed-through terminal, Screw connection, 70 mm², 1000 V, 192 A, Dark Beige

- Feed-through terminal, Screw connection, 70 mm², 1000 V, 192 A, Blue

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Dark Beige

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Blue

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Dark Beige

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Blue

- Feed-through terminal, Screw connection, 240 mm², 1000 V, 415 A, Dark Beige

- Feed-through terminal, Screw connection, 240 mm², 1000 V, 415 A, Blue

-

Feed-through terminal blocks 1-tier ZDU 2.5 - Feed-through terminal, Tension clamp connection, 2.5 mm², 24 A, Dark Beige ZDU 2.5 BL - Feed-through terminal, Tension clamp connection, 2.5 mm², 800 V, 24 A, Blue ZDU 4 - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Dark Beige ZDU 4 BL - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Blue ZDU 6 - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A, Dark Beige ZDU 6 BL - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A,Blue ZDU 10 - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Dark Beige ZDU 10 BL - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Blue ZDU 16 - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Dark Beige ZDU 16 BL - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Blue Feed-through terminal blocks 2-Tier ZDK 2.5 - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Beige ZDK 2.5 BL - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Blue

Feed-through terminal blocks 1-tier ZDU 2.5 - Feed-through terminal, Tension clamp connection, 2.5 mm², 24 A, Dark Beige ZDU 2.5 BL - Feed-through terminal, Tension clamp connection, 2.5 mm², 800 V, 24 A, Blue ZDU 4 - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Dark Beige ZDU 4 BL - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Blue ZDU 6 - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A, Dark Beige ZDU 6 BL - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A,Blue ZDU 10 - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Dark Beige ZDU 10 BL - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Blue ZDU 16 - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Dark Beige ZDU 16 BL - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Blue Feed-through terminal blocks 2-Tier ZDK 2.5 - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Beige ZDK 2.5 BL - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Blue -

Description Spring connection with PUSH IN Technology. The innovative PUSH IN technology reduces the amount of time you spend on wiring to a minimum. Direct insertion guarantees high conductor pull-out forces and simple handling for all conductor types. Industrial

Description Spring connection with PUSH IN Technology. The innovative PUSH IN technology reduces the amount of time you spend on wiring to a minimum. Direct insertion guarantees high conductor pull-out forces and simple handling for all conductor types. Industrial- Oil & Gas

- Chemical & Petrochemical

- Paper

- Steel

- Pulp & Paper

- Electronic

- Renewable Energy

- Transportation

-

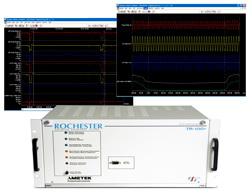

Application The Fault Recorder product family is enhanced with our full suite of software applications designed to simplify the process of configuring our recorders, retrieving event information, and analyzing the results. Tools like our automated event retrieval and expert analysis provide the quickest results when classifying an abnormal event. Detailed fault analysis is easily accomplished with our set of power analysis tools and flexible display options.

Application The Fault Recorder product family is enhanced with our full suite of software applications designed to simplify the process of configuring our recorders, retrieving event information, and analyzing the results. Tools like our automated event retrieval and expert analysis provide the quickest results when classifying an abnormal event. Detailed fault analysis is easily accomplished with our set of power analysis tools and flexible display options. -

Aquaseal Max is a fabricated steel butterfly valve developed as an alternate for cast iron butterfly and sluice valves in water distribution systems. The highly reliable valve also finds application in power plants, utility and fire water lines, and HVAC systems. Customised Aquaseal Max can be used to handle air, gases and vacuum services. The valve has successfully under gone Proof of Design (POD) test as per AWWA C 504 and AWWA C 516. The key feature of Aquaseal Max Fabricated Steel Butterfly Valve is a Self-energising Disc Seal that uses line pressure to provide assured sealing. Special Features & Benefits Self-energising Disc Seal - Bi-directional bubble-tight sealing Assured Sealing to Atmosphere Lighter and Stronger Construction Lower Torque, Longer Life Maintenance-free Bearings

Aquaseal Max is a fabricated steel butterfly valve developed as an alternate for cast iron butterfly and sluice valves in water distribution systems. The highly reliable valve also finds application in power plants, utility and fire water lines, and HVAC systems. Customised Aquaseal Max can be used to handle air, gases and vacuum services. The valve has successfully under gone Proof of Design (POD) test as per AWWA C 504 and AWWA C 516. The key feature of Aquaseal Max Fabricated Steel Butterfly Valve is a Self-energising Disc Seal that uses line pressure to provide assured sealing. Special Features & Benefits Self-energising Disc Seal - Bi-directional bubble-tight sealing Assured Sealing to Atmosphere Lighter and Stronger Construction Lower Torque, Longer Life Maintenance-free Bearings -

Description WAP 2.5-10

Description WAP 2.5-10- W-Series, End plate for WDU 2.5 TO WDU 10, WTR 2.5,WSI 2.5/SI,WSI 6

- W-Series, End plate blue for WDU 2.5 BL TO WDU 10 BL, WTR 2.BL,WSI 6 BL

- W-Series, End plate for WDU 16 TO WDU35, WPE 16 TO WPE 35/ partition plate for WDU 2.5 TO WDU 10, WTR 2.5,WSI 6

- W-Series, End plate blue for WDU 16 TO WDU35, WPE 16 TO WPE 35/ partition plate for WDU 2.5 TO WDU 10, WTR 2.5,WSI 6

- W-Series, End plate for WDK 2.5, WDK 2.5 PE

- W-Series, End plate for WDK 2.5 BL

- W-Series, Seperation plate

- W-Series, End plate for WDK 10

- W-Series, End plate for WDK 10 BL

-

Description ZAP/TW1

Description ZAP/TW1- Z-series, Accessories, End plate, Seperation plate for ZDU 2.5,ZPE 2.5,ZTR2.5

- Z-series, Accessories, End plate, Seperation plate for ZDU 2.5 BL,ZTR 2.5 BL

- Z-series, Accessories, End plate, Seperation plate for ZSI 2.5, ZSI 2.5/LD 28 AC, ZSI 2.5/LD 120 AC, ZSI 2.5/LD250 AC,ZDU 2.5/2X2AN/D+,ZDU 2.5/2X2AN/D-

- Z-series, Accessories, End plate, Seperation plate for ZDU 4

- Z-series, Accessories, End plate, Seperation plate for ZDU 4 BL

- Z-series, Accessories, End plate, Seperation plate for ZDU 6, ZPE 6

- Z-series, Accessories, End plate, Seperation plate for ZDU 6 BL

- Z-series, Accessories, End plate, Seperation plate for ZDU 10, ZPE 10

- Z-series, Accessories, End plate, Seperation plate for ZDU 10 BL

- series, Accessories, End plate for ZDU 16, ZPE 16

- Z-series, Accessories, End plate for ZDU 16 BL

- Z-series, Accessories, End plate, Seperation plate for ZDK 2.5

- Z-series, Accessories, End plate, Seperation plate for ZDK 2.5 BL

-

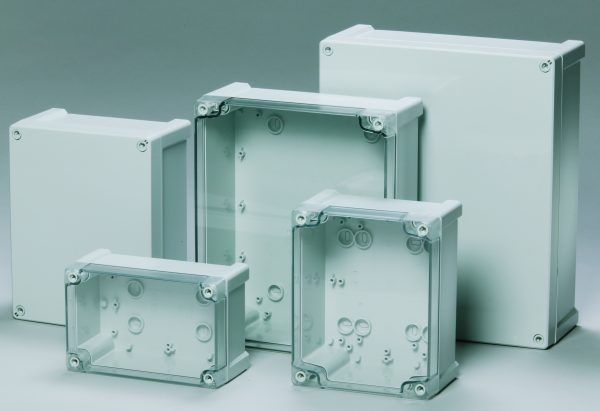

Application As its name suggests, Tempo doesn’t like to hang around. Need an enclosure that’s easy on the pocket and installed in seconds, but still gets the job done? Tempo does all this and still meets high, recognised standards. Related Market Power Generation, Distribution, Oil & Gas, Metals & Mining, Medical, Pulp & Paper, Food & Beverage, Transportation

Application As its name suggests, Tempo doesn’t like to hang around. Need an enclosure that’s easy on the pocket and installed in seconds, but still gets the job done? Tempo does all this and still meets high, recognised standards. Related Market Power Generation, Distribution, Oil & Gas, Metals & Mining, Medical, Pulp & Paper, Food & Beverage, Transportation -

Application Wherever functions, such as push buttons and sensors, need to see the light of day, Piccolo is the neat solution. It’s also modular and adaptable, with a range of sizes and accessories. Related Market Power Generation, Distribution, Oil & Gas, Metals & Mining, Medical, Pulp & Paper, Food & Beverage, Transportation

Application Wherever functions, such as push buttons and sensors, need to see the light of day, Piccolo is the neat solution. It’s also modular and adaptable, with a range of sizes and accessories. Related Market Power Generation, Distribution, Oil & Gas, Metals & Mining, Medical, Pulp & Paper, Food & Beverage, Transportation -

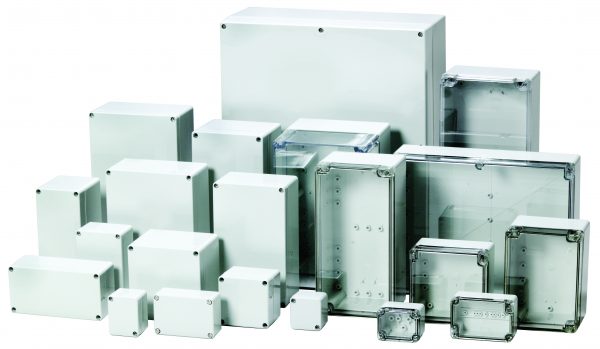

Applications This range offers over 260 versions. Choose MNX if you have a large product family that needs to be housed in matching enclosures with the minimum of fuss, no matter the environment or installation height. For the protection of electrical and electronic components of all kinds. Related Market Power Generation, Distribution, Oil & Gas, Metals & Mining, Medical, Pulp & Paper, Food & Beverage, Transportation

Applications This range offers over 260 versions. Choose MNX if you have a large product family that needs to be housed in matching enclosures with the minimum of fuss, no matter the environment or installation height. For the protection of electrical and electronic components of all kinds. Related Market Power Generation, Distribution, Oil & Gas, Metals & Mining, Medical, Pulp & Paper, Food & Beverage, Transportation -

Application Euronord enclosures come in over 170 standard sizes, meaning huge interchangeability with the products you may already have. The latest addition Euronord 3 range incorporates a number of innovative features, for example quick release corrosion resistant cover screws, and recessed middle area of the cover for membrane keyboards and prints. Related Market Power Generation, Distribution, Oil & Gas, Metals & Mining, Medical, Pulp & Paper, Food & Beverage, Transportation

Application Euronord enclosures come in over 170 standard sizes, meaning huge interchangeability with the products you may already have. The latest addition Euronord 3 range incorporates a number of innovative features, for example quick release corrosion resistant cover screws, and recessed middle area of the cover for membrane keyboards and prints. Related Market Power Generation, Distribution, Oil & Gas, Metals & Mining, Medical, Pulp & Paper, Food & Beverage, Transportation -

Application If you need major impact resistance, then CAB may be the cabinet for you. Think of the harshest and most demanding environments – CAB will not let you down. It will resist weathering and take the knocks better than steel. A wide selection is available. Related Market Power Generation, Distribution, Oil & Gas, Metals & Mining, Medical, Pulp & Paper, Food & Beverage, Transportation

Application If you need major impact resistance, then CAB may be the cabinet for you. Think of the harshest and most demanding environments – CAB will not let you down. It will resist weathering and take the knocks better than steel. A wide selection is available. Related Market Power Generation, Distribution, Oil & Gas, Metals & Mining, Medical, Pulp & Paper, Food & Beverage, Transportation