-

Special Features & Benefits Pressure-seal Gate Valve design conforms to ASME B 16.34. The design was successfully validated by conducting in-house High Pressure High Temperature (HPHT) Gas Tests on ultra-high pressure valve prototypes. Flow Interruption Test successfully conducted on 8" Class 600 Pressure-seal Gate Valve suitable for Main Stream Isolation Valve (MSIV) service in nuclear power plants - at Areva, Germany. Fugitive Emission - 14" Class 2500 Pressure-seal Gate Valve (test pressure of 431 bar at ambient and 289 bar at 400 degree C) has been tested successfully as per ISO 15848-1, endurance Class CO2 and Tightness Class BH CE Marking – Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL3 Safety Integrity Level for Automated Valves Pressure-seal Gate Valves (up to Class 2500) used in Oil & Gas industry tested to ISO 15848-1 Class BH Pressure-seal Gate Valves successfully tested to Shell Design Validation Test 77/300 and witnessed by Shell Inspectors Valves in intermediate classes reduce total cost of ownership Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures. Higher hardfacing thickness (3 mm) to ensure consistent hot hardness Disc guides hardfaced for longer life Customised deposition process in F91/ C12A valves to avoid delamination of hardfaced surfaces Live loading of bonnet bolts for F91/ C12A valves Special high purity graphite packing (seven rings) provided for pressure rating > Class 2500 in Power applications Live loading of bonnet bolts and gland bolts for all valves in F91/ C12A construction

Special Features & Benefits Pressure-seal Gate Valve design conforms to ASME B 16.34. The design was successfully validated by conducting in-house High Pressure High Temperature (HPHT) Gas Tests on ultra-high pressure valve prototypes. Flow Interruption Test successfully conducted on 8" Class 600 Pressure-seal Gate Valve suitable for Main Stream Isolation Valve (MSIV) service in nuclear power plants - at Areva, Germany. Fugitive Emission - 14" Class 2500 Pressure-seal Gate Valve (test pressure of 431 bar at ambient and 289 bar at 400 degree C) has been tested successfully as per ISO 15848-1, endurance Class CO2 and Tightness Class BH CE Marking – Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL3 Safety Integrity Level for Automated Valves Pressure-seal Gate Valves (up to Class 2500) used in Oil & Gas industry tested to ISO 15848-1 Class BH Pressure-seal Gate Valves successfully tested to Shell Design Validation Test 77/300 and witnessed by Shell Inspectors Valves in intermediate classes reduce total cost of ownership Pressure-Seal mechanism utilizes line pressure to enhance seal; ensures sealing integrity at higher operating pressures. Higher hardfacing thickness (3 mm) to ensure consistent hot hardness Disc guides hardfaced for longer life Customised deposition process in F91/ C12A valves to avoid delamination of hardfaced surfaces Live loading of bonnet bolts for F91/ C12A valves Special high purity graphite packing (seven rings) provided for pressure rating > Class 2500 in Power applications Live loading of bonnet bolts and gland bolts for all valves in F91/ C12A construction -

Features Size 2" to 72" (50 mm to 1800 mm) ASME Class Class 150 to 2500 Design Standard API 600, API 603, ASME B 16.34 Special Features & Benefit Gate Valve design complies to API 600, Edition 13 Offered with API 600 monogram Fugitive Emissions - Complies to API 624 and ISO 15848-1 (<50 ppm / Class AH leakage levels, optional) Gate Valves tested to API 624 at Yarmouth Research Lab, Maine, USA Body gasket leakage <100 ppm observed on eight sizes tested as per API 624 Annexure A Fire Safe - By design and tested to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design Examination Certificate (certified by DNV) available Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL 3 Safety Integrity Level for Automated Valves Gate valves successfully tested to Shell Design Validation Test Procedure 77/300 and witnessed by Shell Inspectors Robust stem-wedge design connection successfully tested as per API RP 591 Annex B Hardfaced body guides and wedge slots (sizes >24”) Inconel overlay/ cladded options offered

Features Size 2" to 72" (50 mm to 1800 mm) ASME Class Class 150 to 2500 Design Standard API 600, API 603, ASME B 16.34 Special Features & Benefit Gate Valve design complies to API 600, Edition 13 Offered with API 600 monogram Fugitive Emissions - Complies to API 624 and ISO 15848-1 (<50 ppm / Class AH leakage levels, optional) Gate Valves tested to API 624 at Yarmouth Research Lab, Maine, USA Body gasket leakage <100 ppm observed on eight sizes tested as per API 624 Annexure A Fire Safe - By design and tested to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design Examination Certificate (certified by DNV) available Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL 3 Safety Integrity Level for Automated Valves Gate valves successfully tested to Shell Design Validation Test Procedure 77/300 and witnessed by Shell Inspectors Robust stem-wedge design connection successfully tested as per API RP 591 Annex B Hardfaced body guides and wedge slots (sizes >24”) Inconel overlay/ cladded options offered -

Special Features & Benefits Gate Valve design complies to API 600, Edition 13 Offered with API 600 monogram Fugitive Emissions - Complies to API 624 and ISO 15848-1 (<50 ppm / Class AH leakage levels, optional) Gate Valves tested to API 624 at Yarmouth Research Lab, Maine, USA Body gasket leakage <100 ppm observed on eight sizes tested as per API 624 Annexure A Fire Safe - By design and tested to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design Examination Certificate (certified by DNV) available ATEX - Meets requirements of ATEX Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL 3 Safety Integrity Level certificatation is available Gate valves successfully tested to Shell Design Validation Test Procedure 77/300 and witnessed by Shell Inspectors Robust stem-wedge design connection successfully tested as per API RP 591 Annex B Hardfaced body guides and wedge slots (sizes >24”) Inconel overlay/ cladded options offered

Special Features & Benefits Gate Valve design complies to API 600, Edition 13 Offered with API 600 monogram Fugitive Emissions - Complies to API 624 and ISO 15848-1 (<50 ppm / Class AH leakage levels, optional) Gate Valves tested to API 624 at Yarmouth Research Lab, Maine, USA Body gasket leakage <100 ppm observed on eight sizes tested as per API 624 Annexure A Fire Safe - By design and tested to API 607/ ISO 10497 CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H PED Module B1 Design Examination Certificate (certified by DNV) available ATEX - Meets requirements of ATEX Directive 94/9/EC (ATEX), category 2 non-electrical equipment SIL 3 Safety Integrity Level certificatation is available Gate valves successfully tested to Shell Design Validation Test Procedure 77/300 and witnessed by Shell Inspectors Robust stem-wedge design connection successfully tested as per API RP 591 Annex B Hardfaced body guides and wedge slots (sizes >24”) Inconel overlay/ cladded options offered -

Description WTR 2.5/SI

Description WTR 2.5/SI- W-Series, Fuse terminal, Rated cross-section: 2.5 mm², Screw connection

- W-Series, Fuse terminal, Rated cross-section: 4 mm², Screw connection

- W-Series, Fuse terminal with LED 10-36 VDC/AC, Rated cross-section: 4 mm², Screw connection

- W-Series, Fuse terminal with LED 140-250 VDC/AC, Rated cross-section: 4 mm², Screw connection

- W-Series, Fuse terminal, Rated cross-section: 6 mm², Screw connection, FUSE 5X20 mm

- W-Series, Fuse terminal with LED 10-36 VDC/AC, Rated cross-section: 6 mm², Screw connection, FUSE 5X20 mm

- W-Series, Fuse terminal with LED 250 AC, Rated cross-section: 6 mm², Screw connection, FUSE 5X20 mm

-

AFS 2.5 CF 2C BK -Fuse terminal, PUSH IN, 2.5 mm², 250 V, 10 A, Black AFS 2.5 CF 2C 12V BK - Fuse terminal, PUSH IN, 2.5 mm², 12 V, 10 A, Black AFS 2.5 CF 2C 24V BK - Fuse terminal, PUSH IN, 2.5 mm², 24 V, 10 A, Black AFS 4 2C BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black AFS 4 2C 10-36V BK - Fuse terminal, PUSH IN, 4 mm², 36 V, 6.3 A, Black AFS 4 2C 30-70V BK - Fuse terminal, PUSH IN, 4 mm², 70 V, 6.3 A, Black AFS 4 2C 100-250V BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black

AFS 2.5 CF 2C BK -Fuse terminal, PUSH IN, 2.5 mm², 250 V, 10 A, Black AFS 2.5 CF 2C 12V BK - Fuse terminal, PUSH IN, 2.5 mm², 12 V, 10 A, Black AFS 2.5 CF 2C 24V BK - Fuse terminal, PUSH IN, 2.5 mm², 24 V, 10 A, Black AFS 4 2C BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black AFS 4 2C 10-36V BK - Fuse terminal, PUSH IN, 4 mm², 36 V, 6.3 A, Black AFS 4 2C 30-70V BK - Fuse terminal, PUSH IN, 4 mm², 70 V, 6.3 A, Black AFS 4 2C 100-250V BK - Fuse terminal, PUSH IN, 4 mm², 250 V, 6.3 A, Black -

DescriptionZSI ZSI 2.5

DescriptionZSI ZSI 2.5- Z-series, Fuse terminal, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

- Z-series, Fuse terminal with LED 28VAC, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

- Z-series, Fuse terminal with LED 120VAC, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

- Z-series, Fuse terminal with LED 250VAC, Rated cross-section: 2.5 mm², Tension clamp connection, Dark Beige, Direct mounting

-

Functional components The following products are available as functional components: Switch and button components in a sealed built-in EG2 enclosure Rectifier and fuse components in a sealed built-in EG2 enclosure Logic components with AND, NAND, OR and NOR operators Diode gates with up to 40 inputs in open design Components modules for the integration of electronic elements Serial interface converter, and AD / DA converter Industrial

Functional components The following products are available as functional components: Switch and button components in a sealed built-in EG2 enclosure Rectifier and fuse components in a sealed built-in EG2 enclosure Logic components with AND, NAND, OR and NOR operators Diode gates with up to 40 inputs in open design Components modules for the integration of electronic elements Serial interface converter, and AD / DA converter Industrial- Oil & Gas

- Chemical & Petrochemical

- Paper

- Steel

- Pulp & Paper

- Electronic

- Renewable Energy

- Transportation

-

Application Designed to house systems incorporating large components or complex mounting configurations. Three-point latching and sealing provide industry-leading protection from dust, dirt, oil and water. These enclosures are used in machine tool applications for housing motor starters, drives, contactors and PLCs, as well as a wide variety of other electrical and electronic equipment. The addition of 19-in. rack-mounting accessories makes these enclosures ideal for providing rugged protection for sensitive rack-mounted components in harsh industrial environments. These enclosures are used extensively in automotive, pulp and paper, wood products, textile and similar industries. Size 60.06 x 48.06 x 18.06 - 90.06 x 72.06 x 36.06

Application Designed to house systems incorporating large components or complex mounting configurations. Three-point latching and sealing provide industry-leading protection from dust, dirt, oil and water. These enclosures are used in machine tool applications for housing motor starters, drives, contactors and PLCs, as well as a wide variety of other electrical and electronic equipment. The addition of 19-in. rack-mounting accessories makes these enclosures ideal for providing rugged protection for sensitive rack-mounted components in harsh industrial environments. These enclosures are used extensively in automotive, pulp and paper, wood products, textile and similar industries. Size 60.06 x 48.06 x 18.06 - 90.06 x 72.06 x 36.06 -

Application These enclosures are ideal for mounting equipment on panels or racks in indoor or outdoor applications where it is necessary to protect controls and instrumentation from wet, non-corrosive environments. The design features Hoffman’s exclusive PowerGlide Handle with 3-point latching for secure closure. Size 72.06 x 25.06 x 18.06 - 72.06 x 37.06 x 24.06

Application These enclosures are ideal for mounting equipment on panels or racks in indoor or outdoor applications where it is necessary to protect controls and instrumentation from wet, non-corrosive environments. The design features Hoffman’s exclusive PowerGlide Handle with 3-point latching for secure closure. Size 72.06 x 25.06 x 18.06 - 72.06 x 37.06 x 24.06 -

Application Designed to house systems incorporating large components or complex mounting configurations. Three-point latching and sealing provide industry-leading protection from dust, dirt, oil and water. These enclosures are used in machine tool applications for housing motor starters, drives, contactors and PLCs, as well as a wide variety of other electrical and electronic equipment. The addition of 19-in. rack-mounting accessories makes these enclosures ideal for providing rugged protection for sensitive rack-mounted components in harsh industrial environments. These enclosures are used extensively in automotive, pulp and paper, wood products, textile and similar industries. Four styles are available to provide maximum flexibility Size 60.06 x 24.06 x 18.06 - 90.06 x 36.06 x 36.06

Application Designed to house systems incorporating large components or complex mounting configurations. Three-point latching and sealing provide industry-leading protection from dust, dirt, oil and water. These enclosures are used in machine tool applications for housing motor starters, drives, contactors and PLCs, as well as a wide variety of other electrical and electronic equipment. The addition of 19-in. rack-mounting accessories makes these enclosures ideal for providing rugged protection for sensitive rack-mounted components in harsh industrial environments. These enclosures are used extensively in automotive, pulp and paper, wood products, textile and similar industries. Four styles are available to provide maximum flexibility Size 60.06 x 24.06 x 18.06 - 90.06 x 36.06 x 36.06 -

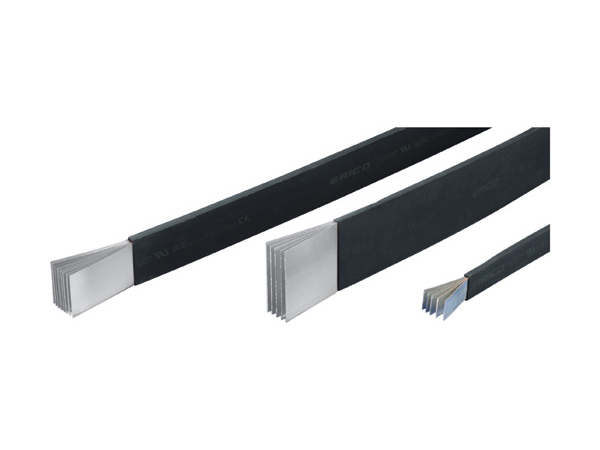

Features TD Compact Four Pole Distribution Block

Features TD Compact Four Pole Distribution Block- Minimum space for maximum power

- Protection cover and insulating screens are transparent

- Insulating screen between each row

- Easy and safe connections

- Easily clips onto DIN rail or mounts to panel with screws

- Solid bars provide reliability

- Wiring with or without terminal

- Halogen free

- RoHS compliant

- Connect nVent ERIFLEX Flexibar, insulated braided conductor or cable with lug on line side

- Tinned copper bars allows for copper or aluminum cable

- Transparent protection covers

- Easy and safe connections

- Easily clips onto DIN rail or mounts to panel with screws

- Solid bars provide reliability

- Input separated from outputs

- Supports wiring from both sides

- Design allows for visual inspection of conductor and confirmation of connection

- Large end terminals

- High percentange of fill ratio

- Wiring with or without terminal

- Halogen free

- RoHS compliant

- Attaches to four pole distribution blocks for increased wire capacity

- Direct electrical connection

- Strong mechanical assembly

- Transparent protection cover

- Halogen free

- RoHS compliant

-

Features Floating Ball Valves Size 1/2" to 8" | ASME Class Class 150 to 2500 ISO 17292 | API 6D | API 608 1 Piece / 2 Piece / 3 Piece Construction Full / Reduced bore Soft Seat & Metal seat | Flanged-Screwed-Socket weld

Features Floating Ball Valves Size 1/2" to 8" | ASME Class Class 150 to 2500 ISO 17292 | API 6D | API 608 1 Piece / 2 Piece / 3 Piece Construction Full / Reduced bore Soft Seat & Metal seat | Flanged-Screwed-Socket weld- Mirror-finished solid stainless ball

- Fine-grained PTFE seats with Cavity Pressure Relief mechanism

- Blowout-proof stem & Antistatic feature

- High integrity stem sealing – Belleville springs compensate for wear and thermal expansions

- Actuator-mounting flange conforms to ISO 5211

-

Flexible heaters are very versatile and provide solutions to a vast number of low-to-medium temperature applications. Heaters are manufactured with rugged light-weight materials providing chemical and moisture resistance with operating temperatures to 392°F. Wire elements are durable and wound precisely within the structure for optimal performance. A variety of electrical, shape and contour fittings to meet many specifications.

Flexible heaters are very versatile and provide solutions to a vast number of low-to-medium temperature applications. Heaters are manufactured with rugged light-weight materials providing chemical and moisture resistance with operating temperatures to 392°F. Wire elements are durable and wound precisely within the structure for optimal performance. A variety of electrical, shape and contour fittings to meet many specifications. -

Flat-blade connection The traditional single-wire connection – versatile, simple and cost-effective: PCB terminals with cable-lug connection – the PCF system. High current-carrying capacity up to 24 A (IEC) or 15 A (UL) 3 pitches (5.0 / 7.5 / 10.0 mm) for voltages up to 1000 V (IEC) or 300 V (UL) 3 outlet directions in relation to the PCB (90 / 135 / 180°) For mounting side by side or fixed number of poles, between 2 and 19 connector lugs Can be used with 2.8 and 6.3 mm flat blade receptacles Suitable for insulated and uninsulated receptacles For applications requiring the quick and easy connection of pre-assembled conductors to PCBs. A simple solution for simple connections: inexpensive Faston connection system for PCBs. Industrials

Flat-blade connection The traditional single-wire connection – versatile, simple and cost-effective: PCB terminals with cable-lug connection – the PCF system. High current-carrying capacity up to 24 A (IEC) or 15 A (UL) 3 pitches (5.0 / 7.5 / 10.0 mm) for voltages up to 1000 V (IEC) or 300 V (UL) 3 outlet directions in relation to the PCB (90 / 135 / 180°) For mounting side by side or fixed number of poles, between 2 and 19 connector lugs Can be used with 2.8 and 6.3 mm flat blade receptacles Suitable for insulated and uninsulated receptacles For applications requiring the quick and easy connection of pre-assembled conductors to PCBs. A simple solution for simple connections: inexpensive Faston connection system for PCBs. Industrials- Electronic

- Other

-

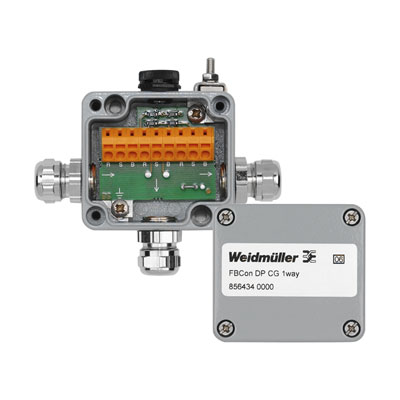

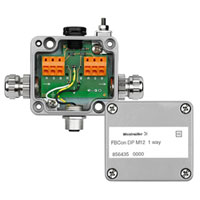

Field bus components The FBCon Fieldbus distributor is available in the industry and EEx (ia) version. They are used for coupling from 1 to 8 field devices or sensors. They are connected via spur lines. The connection to the spur line can be made with an M12 plug or directly via an EMC cable gland. Communication and device power feed are transferred by a common 2-wire line. The distributors offer the following features respective of the version: Tension-clamp connection system Overvoltage protection for the main line Current limiter for each branch line EMC cable gland M12 plug-in connectors External earthing contact Interruption-free bus operation Industrial version Bus termination integrated (not EX) ATEX explosion-proof version Pressure-equalising element Protection degrees IP65, IP66, IP67 Stainless steel versions PROFIBUS-PA compatible Industrial

Field bus components The FBCon Fieldbus distributor is available in the industry and EEx (ia) version. They are used for coupling from 1 to 8 field devices or sensors. They are connected via spur lines. The connection to the spur line can be made with an M12 plug or directly via an EMC cable gland. Communication and device power feed are transferred by a common 2-wire line. The distributors offer the following features respective of the version: Tension-clamp connection system Overvoltage protection for the main line Current limiter for each branch line EMC cable gland M12 plug-in connectors External earthing contact Interruption-free bus operation Industrial version Bus termination integrated (not EX) ATEX explosion-proof version Pressure-equalising element Protection degrees IP65, IP66, IP67 Stainless steel versions PROFIBUS-PA compatible Industrial- Oil & Gas

- Chemical & Petrochemical

- Paper

- Steel

- Pulp & Paper

- Electronic

- Renewable Energy

- Transportation

-

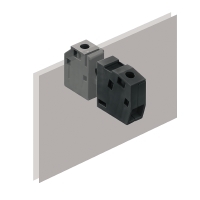

6 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. The innovative PUSH IN connection system from Weidmüller makes for a simple, tool-free wire connection on the inside and outside of devices. The sliced design and an intuitive fastening mechanism enable high-density blocks to be constructed quickly and easily. Industrial

6 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. The innovative PUSH IN connection system from Weidmüller makes for a simple, tool-free wire connection on the inside and outside of devices. The sliced design and an intuitive fastening mechanism enable high-density blocks to be constructed quickly and easily. Industrial- Electronic

- Other

-

25 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. Various types of connection on the inside, such as cable lug connections which can be encapsulated (WGK …VP) and maintenance-free clamping yoke screw connections (WGK…) with vertical and horizontal wire insertion provide the optimal connection for any installation situation. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial

25 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. Various types of connection on the inside, such as cable lug connections which can be encapsulated (WGK …VP) and maintenance-free clamping yoke screw connections (WGK…) with vertical and horizontal wire insertion provide the optimal connection for any installation situation. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial- Electronic

- Other

-

16 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. Different types of connection on the inside, such as a solder connection which can be encapsulated (WGK …VP) or a maintenance-free clamping yoke screw connection (WGK…) with vertical and horizontal wire connections, provide the optimal connection for any installation situation. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial

16 mm² : The high-current feed-through terminals of the WGK series provide a universal solution for feeding currents of different magnitude through the enclosure wall. Different types of connection on the inside, such as a solder connection which can be encapsulated (WGK …VP) or a maintenance-free clamping yoke screw connection (WGK…) with vertical and horizontal wire connections, provide the optimal connection for any installation situation. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial- Electronic

- Other

-

10 mm² : Optimal connection options for use in encapsulated devices (e.g. EMC filters and/or fully insulated transformers) The V versions of the WGK feed-through terminals with an insulated housing and clamping yoke connection on the outside, and a solder connection on the inside. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial

10 mm² : Optimal connection options for use in encapsulated devices (e.g. EMC filters and/or fully insulated transformers) The V versions of the WGK feed-through terminals with an insulated housing and clamping yoke connection on the outside, and a solder connection on the inside. The different peg types allow for a simple and quick assembly of multi-pole blocks. Industrial- Electronic

- Other

-

Feedthrough terminals for devices - OMNIMATE Power The universal solution to feed power through housing walls. Excellent for applications such as EMC filters, discrete-built inverters for drive systems and encapsulated devices. Select from our wide-ranging programme: · 4 mm²A wide service portfolio for currents up to 232 A and conductor cross-sections from 4 to 95 mm² (AWG 4/0) · Different types of connections such as a castable soldering connection, cable lug bolt connection and service-free clamping yoke screw connection and PUSH IN spring connection · Structural shapes for horizontal or vertical outgoing cable Industrial

Feedthrough terminals for devices - OMNIMATE Power The universal solution to feed power through housing walls. Excellent for applications such as EMC filters, discrete-built inverters for drive systems and encapsulated devices. Select from our wide-ranging programme: · 4 mm²A wide service portfolio for currents up to 232 A and conductor cross-sections from 4 to 95 mm² (AWG 4/0) · Different types of connections such as a castable soldering connection, cable lug bolt connection and service-free clamping yoke screw connection and PUSH IN spring connection · Structural shapes for horizontal or vertical outgoing cable Industrial- Electronic

- Other

-

Description WDK 2.5

Description WDK 2.5- Feed-through terminal, Double-tier terminal, Screw connection, 2.5 mm², 400 V, 24 A, Dark Beige

- Feed-through terminal, Double-tier terminal, Screw connection, 2.5 mm², 400 V, 24 A, Blue

- Feed-through terminal, Double-tier terminal, Screw connection, 10 mm², 800 V, 57 A, Dark Beige

- Feed-through terminal, Double-tier terminal, Screw connection, 10 mm², 800 V, 57 A, Blue

-

Description WDU 2.5

Description WDU 2.5- Feed-through terminal, Screw connection, 2.5 mm², 800 V, 24 A, Dark Beige

- Feed-through terminal, Screw connection, 2.5 mm², 800 V, 24 A, Blue

- W-Series, Feed-through terminal, Thermocouple TYPE K, Rated cross-section: 2.5 mm², Screw connection

- Feed-through terminal, Screw connection, 4 mm², 800 V, 32 A, Dark Beige

- Feed-through terminal, Screw connection, 4 mm², 800 V, 32 A, Blue

- Feed-through terminal, Screw connection, 6 mm², 800 V, 41 A, Dark Beige

- Feed-through terminal, Screw connection, 6 mm², 800 V, 41 A, Blue

- Feed-through terminal, Screw connection, 10 mm², 1000 V, 57 A, Dark Beige

- Feed-through terminal, Screw connection, 10 mm², 1000 V, 57 A, Blue

- Feed-through terminal, Screw connection, 16 mm², 1000 V, 76 A, Dark Beige

- Feed-through terminal, Screw connection, 16 mm², 1000 V, 76 A, Blue

- Feed-through terminal, Screw connection, 35 mm², 1000 V, 125 A, Dark Beige

- Feed-through terminal, Screw connection, 35 mm², 1000 V, 125 A, Blue

- Feed-through terminal, Screw connection, 50 mm², 1000 V, 150 A, Dark Beige

- Feed-through terminal, Screw connection, 50 mm², 1000 V, 150 A, Blue

- Feed-through terminal, Screw connection, 70 mm², 1000 V, 192 A, Dark Beige

- Feed-through terminal, Screw connection, 70 mm², 1000 V, 192 A, Blue

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Dark Beige

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Blue

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Dark Beige

- Feed-through terminal, Screw connection, 120 mm², 1000 V, 269 A, Blue

- Feed-through terminal, Screw connection, 240 mm², 1000 V, 415 A, Dark Beige

- Feed-through terminal, Screw connection, 240 mm², 1000 V, 415 A, Blue

-

Feed-through terminal blocks 1-tier ZDU 2.5 - Feed-through terminal, Tension clamp connection, 2.5 mm², 24 A, Dark Beige ZDU 2.5 BL - Feed-through terminal, Tension clamp connection, 2.5 mm², 800 V, 24 A, Blue ZDU 4 - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Dark Beige ZDU 4 BL - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Blue ZDU 6 - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A, Dark Beige ZDU 6 BL - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A,Blue ZDU 10 - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Dark Beige ZDU 10 BL - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Blue ZDU 16 - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Dark Beige ZDU 16 BL - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Blue Feed-through terminal blocks 2-Tier ZDK 2.5 - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Beige ZDK 2.5 BL - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Blue

Feed-through terminal blocks 1-tier ZDU 2.5 - Feed-through terminal, Tension clamp connection, 2.5 mm², 24 A, Dark Beige ZDU 2.5 BL - Feed-through terminal, Tension clamp connection, 2.5 mm², 800 V, 24 A, Blue ZDU 4 - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Dark Beige ZDU 4 BL - Feed-through terminal, Tension clamp connection, 4 mm², 800 V, 32 A, Blue ZDU 6 - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A, Dark Beige ZDU 6 BL - Feed-through terminal, Tension clamp connection, 6 mm², 800 V, 41 A,Blue ZDU 10 - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Dark Beige ZDU 10 BL - Feed-through terminal, Tension clamp connection, 10 mm², 1000 V, 57 A, Blue ZDU 16 - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Dark Beige ZDU 16 BL - Feed-through terminal, Tension clamp connection, 16 mm², 1000 V, 76 A, Blue Feed-through terminal blocks 2-Tier ZDK 2.5 - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Beige ZDK 2.5 BL - Feed-through terminal, Double-tier terminal, Tension clamp connection, 2.5 mm², 500 V, 20 A, Blue